Comprehensive guide to programming the Universal PID Banbitebq temperature control

Learn how to set up the Universal PID Banbitebq Temperature Control System. Discover its setup and application to obtain precise temperatures.

1. Introduction

In the realm of modern technology, Universal PID (Proportional-Integral-Derivative) controllers, such as the Banbitebq system, have become instrumental in achieving precise temperature regulation. The guide provides a detailed understanding of the components, configuration, and uses for Universal PID Banbitebq's temperature control system. This process is useful for both professionals and enthusiasts. It can lead to many opportunities, including in the industrial, medical, or domestic setting.

2. Understanding Universal PID Control

Understanding the core functions of a PID is essential to programming it. To maintain the set temperature, a PID controller uses three components that are interconnected:

Proportional: Responds to current errors by displaying a response that is proportional to difference between desired and actual temperatures.

Integral: Corrects past mistakes, maintaining the stability of the system over time.

Derived (D) This derivative focuses on the prevention of abrupt changes, by adjusting to error rates.

Banbitebq Universal PID System is distinguished by its advanced features such as accuracy and user-friendly interfaces. It can also be adapted to a variety of applications. This makes it an extremely versatile tool.

3. Required Components

The following are required to set up the Universal PID Banbitebq Temperature Control System:

PID controller: A core component of the temperature control system.

Sensors of Temperature: Choose devices like thermocouples and RTDs based on their compatibility with Banbitebq.

Heater or Cooler: Element such as fans, heaters or Peltier Modules.

Power supply: Supplies energy to the controller, and any connected components.

Microcontroller Optional: Allows for advanced programming and customization specific to use cases.

You are now ready to start the programing process.

4. Installing the Banbitebq System

Setup is essential to ensure your system runs efficiently and safely. These steps will help you:

Connecting a Temperature sensor: Attache the sensor to designated input terminals of the PID controller. Check that the type of sensor matches controller specifications.

Connecting the Heating Element or the Cooling Element to the Controller: Securely attach the heating element or the cooling element at the output terminal.

Setting Power Connections: Use a suitable power source to energize your controller. All connections must be insulated.

Safety Measures: Install fuse and relays in order to ensure safety and prevent damage.

This stage is crucial for the success of a temperature-control system.

5. Programming Universal PID Controller

To achieve the best results, programming Banbitebq requires a systematized approach.

Enter the desired temperature (Setpoint). Start by entering the temperature that you want to maintain. Setpoint is the target temperature for your system.

Set PID Parameters Change the integral, proportional and derivative values. They are essential for maintaining a balance between responsiveness and stabilty. Banbitebq controllers often feature automatic tuning, which simplifies this process.

Test-and-Optimize: Active the system and monitor its performance. Watch how fast it gets to the setpoint, and if it stays stable. Adjust the PID to minimize overshooting and lag.

You can control temperatures with precision by carefully programming your controller.

6. Application of the Banbitebq System

Universal PID Banbitebq is known for its flexibility. Here are a few real-world examples:

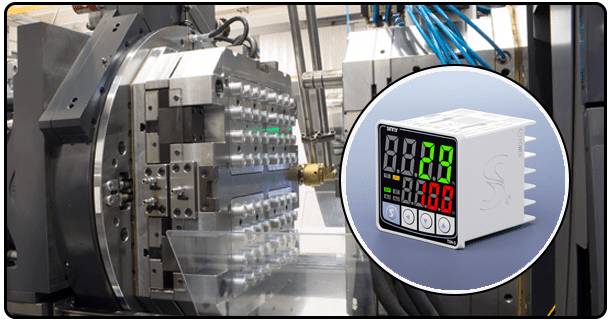

Industrial Manufacturing Regulation of temperature in furnaces, ovens and molding machines

Medical equipment: Keeping critical conditions of devices such as incubators and sterilizers.

HVAC Systems Provide consistent climate control in buildings.

Lab Experiments: Ensure precise environmental conditions for Scientific Research

Food and Beverage Process: Controlling fermentation and cooking processes.

The Banbitebq System has been a staple in many industries because of its adaptability.

7.Optimization and Maintenance

It is important to maintain your system regularly in order to extend its life and ensure reliability. These are some helpful tips.

Check Connections: Conduct regular checks on the wiring and sensors connections to check for damage or wear.

Calibrate the Sensors: Regularly calibrate temperature sensors in order to maintain accuracy.

Components to Clean: Maintain the system in a clean condition so that dust and debris do not affect performance.

Monitor performance: Constantly monitor the system behavior, and correct any deviations.

The system will be more efficient and effective with optimization efforts such as fine tuning PID parameters.

The Universal PID Banbitebq Temperature Control System is an invaluable skill, combining technical know-how with real world application. Understanding its wiring and programming will allow you to harness the system's capabilities for precise temperature control across many applications. The Banbitebq System is a reliable and innovative solution for both industrial applications as well as personal projects.

- How to program a PID temperature controller

- Engineers' Guide to PID temperature control system using PLC