Guide to Industrial Control: SSR and Mechanical Relays for PID Temperature Control

Learn how to master PID temperature control relays using our guide. Learn how to wire mechanical and SSR relays correctly, repair failures, optimize temperature control systems, and compare the two.

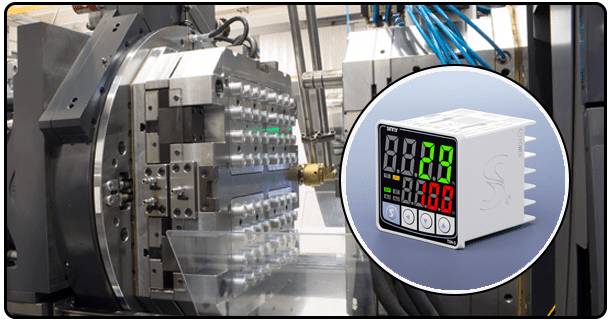

1. Introduction to the Critical Role Relays Play in PID Control

The relay is the interface that connects PID controllers with physical thermal systems. It translates microsecond decisions to kilowatt scale power switching. According to industrial data, 68% of PID shutdowns are caused by relay failures. (IEEE Transactions on Industrial Electronics 2023). When a PID controller calculates the required heating/cooling adjustment, the relay executes this command by connecting/disconnecting power to heaters, chillers, or actuators. A suboptimal selection of relays or their installation can lead to temperature overshoots, contact welding or catastrophic failures. This guide explores the architectures of relays, deployment methods, and strategies for failure mitigation essential to industrial reliability.

2. SSR vs. Mechanical Relays

Mechanical relays are fundamentally different from solid-state (SSR) relays in terms of switching cycles, noise tolerence, operational lifetime, and performance.

Parameter

Relay

Solid-State Relay

Operating Principle

The coil's magnetic field closes the physical contact

Loading of triac/thyristor semiconductor switches

Omron’s engineering guide prioritizes mechanical relays in "low cost installations below 5A" while endorsing the SSRs "for high-frequency switching beyond 100 operations/minute".

Crydom’s thermal analysis confirmed that SSRs require heatsinks when loads exceed 5A in order to prevent overheating ( Crydom Handbook).

3. Selecting Relays Criteria

A. A.

Resistive loads (Heaters). Size the relays to 125% load current.

Inductive Loads (Motors/Compressors): Apply 50% derating (e.g., 20A relay for 10A motor).

Capacitive Loads (Solenoid Valves): Incorporate inrush current limiters.

B. B. Electrical Specifications

Control voltage: Match output PID (5VDC/12VDC/AC)

Load voltage: Verify that the relay can support system voltage (within +-10% tolerance).

Isolation voltage: >2.5kV (UL 508) for systems 240VAC.

C. Environmental Ratings

Temperature: from -40degC up to 85degC. (SSRs perform better in extreme temperatures).

Humidity: IP65 for washdown environments.

Certificates: UL 508. IEC 61810. CE.

4. Wiring & Installation Protocol

Safety Lockout Step 1

Use CAT III multimeter 1000V to de-energize the circuits.

Step 2: Mounting the Relay

SSRs:

Thermal paste is applied in 0.1mm thick.

Install heatsink (>=0.5degC/W) using 0.6Nm of torque.

Mechanical Relays

End stoppers are used to secure DIN rails (compliant with EN 50022).

Step 4: Connecting

Control Circuit:

Connect the PID output coil to the relay coil. Maximum wire resistance is 2O/100ft.

Noise reduction with shielded twisted pair.

Load Circuit:

The 12AWG cable is rated at =15A and 105degC (THHN).

Install a fast-acting fuse (150 % load current).

Step 4: Protection Circuits

Snubber networks (100O + 0.01mF) between mechanical relay contacts.

SSRs with inductive kickback can be handled by SSRs using Varistors.

Visual guide: AutomationDirect wiring diagrams demonstrate "EMI minimized routing for thermocouple/relay Coexistence".

5. Calibration & Configuration

Output modes for PID relays

Time-Proportioning Control (PWM):

Cycle time can be adjusted (SSR 1-2 seconds; mechanical 8-12 seconds).

Duty cycle = Max power x (Output Power/Max Power).

On/Off Control:

Set the hysteresis (0.5-1degC). This will prevent relay chatter.

Calibration procedure

Integral time (I), set to 50%, is the time it takes for a process to respond.

Use clamp meter for inrush spikes monitoring (10x steady state).

Validate stability: +-0.25degC fluctuation after 3 cycles.

6. Problem-solving Relay Failures

Symptom

Diagnosis

Resolution

The heater does not activate

Contacts with burnt/welded coils

Add RC snubber to relay

Overheating relay

Undersized SSR heatsink

Upgrade heatsink (<=0.3degC/W)

Random Cycling

EMI Interference

Shield cables with ferrite cores

Audible buzzing

Low Control Voltage

Check PID output >80% of relay rating

Protocol for Measurement:

Check contact resistance with Fluke 87V (0.2O closed)

Thermometer to measure heatspots on SSR heatsinks.

Referenc: Fluke claims that "85% of all relay failures can be detected via voltage drop tests" (Fluke Testing).

7. Advanced Applications

Cascade Control:

The primary PID controls the heater through SSR.

Mechanical relay activated by secondary PID for cooling auxiliary.

Redundancy Systems:

Parallel SSRs and current-sharing resistors.

Phase-Angle Firing:

The Zero Cross SSRs reduce the inrush of traffic during AC peak.

8. FAQs

Can I retrofit an old mechanical relay to a SSR?

You can, however you must confirm that PID output supports PWM and then recalculate the heat dissipation. Modern controllers have configurable output mode.

Q2 - Why is relay chatter occurring during autotuning?

Rapid corrections are caused by excessive integral gains. Set hysteresis at 1degC and enable the "cycle time" option in PID settings.

Q3 - How can I test the relay function offline?

1. Disconnect all wires.

2. Use the continuity mode on your multimeter: The coil pins must show resistance between 50 and 500O.

3. Use control voltage. Load terminals must show continuity of 0.5O.

9. Conclusion & CTA

The selection of relays is the key to achieving electromechanical precision in PID algorithms. Solid-state variants are more durable in applications with high frequency (>100 cycles/day), whereas electromechanical relays can be used for moderate duty scenarios. According to the ABB Journal of Industrial Automation (2024), failure rates can be reduced by up to 73% when derating, thermal management, and EMI shielding are adhered to. Implement redundant relays for mission-critical applications and conduct quarterly contact resistance testing.

- PID Temperature Controller Mounting Guide: DIN Rail, Panel & Surface Methods | Expert

- PID Sous Vide Controls: Precision of +-0.1degC for perfect results