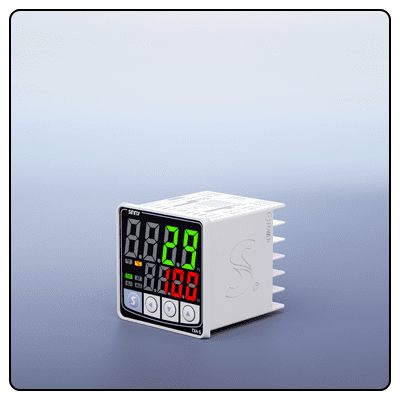

Instantaneous precision control with Plug-and Play PID temperature controllers

Discover plug-and-play PID temperature controllers - simplify your temperature control projects! These auto-sensing devices are easy to install and offer precise PID regulation. You'll find tips on selection, installation, and the best applications for industrial, laboratory, or home use. Temperature control made easy.

1. Introduction: Instant and Reliable temperature control is a necessity

The regulation of temperature is essential in a wide range of applications and industries, from home comfort to precision scientific research or the harsh conditions of manufacturing. It is important to maintain specific temperatures, not only for efficiency, but also for product quality and reproducible results. This level of control is traditionally achieved by carefully integrating a temperature sensing unit, an advanced controller that executes the PID algorithm and a control actuator. While powerful, this setup can be a challenge due to the complexity of wiring, installation, and human error.

Plug-and-play PID controllers are a major advancement in thermal management. They allow for a more democratized access to automated, precise temperature control. The controllers combine key functions, such as sensor detection and configuration automatically, in a single package. The plug-and play nature of these controllers simplifies installation and makes sophisticated PID controls accessible to even users with little technical knowledge or limited time. Plug-and-play PID Controllers are a popular option for applications that require rapid temperature control. They offer reliability, speed and ease-of-use by automating initial set-up and minimizing wiring.

2. What is Plug-and Play?

How the PID loop's core components are configured and integrated is a crucial factor in determining how easy it will be to implement. In traditional PID controllers, the user is often required to select and configure sensor types manually, set PID parameters and connect carefully sensors, actuators and power sources. Manually configuring PID parameters, selecting sensor types, connecting sensors, actuators, and power sources can take a lot of time, be prone to error, and require specialized knowledge.

In the context of PID Controllers, "plug and play" refers to a philosophy of design that seeks to reduce manual input. Plug-and-play PID Controllers are designed to be ready for use right out of the box. Auto-sensing technologies are often used to identify and configure the connected sensor automatically. Many models allow the user to set the initial parameters of the controller, including the temperature setpoint, hysteresis, and the difference between upper and lower setspoints, with little input. The controller is ready for operation with little fuss. This contrasts sharply with standard PID controllers that require a more complicated setup.

The plug-and play approach simplifies everything, from the initial installation through to the basic operation. It does this by automating many tasks based on hardware connected. It is important to achieve reliable temperature control while reducing complexity and user work.

3. What are the main advantages of choosing a plug-and play PID controller? The design philosophy of plug-andplay offers many compelling benefits over more traditional and complex PID systems. This makes them especially attractive in modern applications, where speed, ease-of-use, and simplicity of operation is paramount.

Installation Time and Complexity are Reduced Dramatically: This is the most important benefit. The initial configuration of the system is automatically configured and many of the connections (sensor or actuator or both) are pre-wired. This allows the user to simply connect the power, attach a sensor probe and connect an actuator (if it is not already integrated). The traditional approach requires manual wiring and meticulous component matching.

Reduction of Setup Time and Work: The initial configuration is simplified beyond just the installation. Users can spend more time using the controller because of features like automatic sensor detection, automated tuning algorithms (in certain advanced models), or predefined setpoints. It is especially useful in situations where technicians are required to quickly install several units or have limited technical knowledge.

No Technical Experience Required: Plug and play controllers lower the barrier of entry to implement sophisticated PID controls. Users with little or no background in electronics, control theory, or even basic electronic principles can successfully operate and deploy a PID Controller thanks to the intuitive interfaces. It is now possible to control temperature in different settings by non-technical personnel, hobbyists and students.

Less Risk of Error by the User During Setup Manual Configuration Steps are a Common Source of Error in Traditional PID Setups. This can result in unstable control, wrong temperatures or even damage to equipment. Plug-and-play controllers reduce the risk of user error by automating these configuration steps. This leads to a more stable and reliable operation.

Scalability and Quick Configuration (Where applicable): Although the initial set-up is plug-and play, advanced models have user-friendly GUIs to change settings, view logs or adjust advanced settings at a later date. It allows rapid reconfiguration when needs change. Some systems may also allow for easy network integration or daisy chaining to control multiple units or zones.

Improved Reliability through Simplified Connections: Less manual connections means fewer failure points. Pre-connecting sensors and actuators, where applicable, ensures compatibility. It also reduces the chance of incorrect or loose connections or wires that can compromise performance and safety.

4. Key Features of Plug-and Play PID controllers

These controllers rely on specific features for their rapid deployment and ease of use. The features have been designed to automate and streamline the configuration and setup process.

Auto Sensing: One of the core features is to detect automatically the type and range of the temperature sensor (e.g. specific thermocouple models like K,J,T,E; RTD common types such as PT100 or PT1000). It eliminates manual selections in the menu of the controller, saving you time and decreasing the chances that the wrong configuration is selected.

Auto Configuration: Based on autosensing and plug-and play controllers, many configure parameters automatically based on detected sensors. It could be setting up the output range of the sensor, selecting the right input range, or calculating the initial gains for PID. Some even use an auto-tuning process to optimise the response of their control loop.

Inputs and outputs pre-wired: Plug-and-play Controllers come equipped with terminals that are already wired for sensors and actuators commonly found in standard applications. It might, for example, have terminals that are suitable for standard thermocouple sensors or common heating elements. Standardization eliminates the need for users to connect and source potentially incompatible parts.

User-Friendly Interfaces: The ease of use can be enhanced with user-friendly interfaces. It could be as simple as a graphical LCD screen with menus and touch buttons or a computer or smartphone software or app that walks the user through setting up and operating. It is important to simplify the navigation of controller functions.

Connectivity options that are standard: Plug-and-play controllers include connectivity features to facilitate remote monitoring and control. These could include USB to transfer data or configure software, Wi-Fi, Ethernet, for remote access and network integration, or Modbus, depending on which model is targeted.

Basic safety features: Simplicity is important, but so is safety. The majority of plug-and play controllers have basic safety features such as low and high temperature alarms that can activate alerts or safety shutdowns.

5. Plug and Play PID controllers excel in Ideal Applications

Plug-and-play PID Controllers are suited to a wide range of applications that require precise temperature regulation and speed.

Consumer Electronics and appliances: Plug-and-play controllers for PIDs in smart homes are perfect for managing temperature sensitive electronic equipment, creating stable environments to accommodate specific appliances such as smart ovens or advanced coffee machines requiring temperature precision control.

Education and Hobbyists Use: Plug-and-play controllers are a simple way for universities, colleges and hobbyists to integrate PID controls into projects that involve robotics or electronics prototyping. They can also be used in science experiments that require temperature control, such as incubators, chemical reactions chambers and soldering stations. They are easy to set up, allowing educators to concentrate on the teaching of principles instead of installation. Hobbyists also can easily experiment with them without any technical expertise.

Small Businesses and Retail: Plug-and-play options are a quick and easy way to regulate temperature in settings such as small cafés that have precision brewing machines, retail environments with temperature-controlled displays for certain products (i.e. medication or food), and kiosks. They offer an efficient and effective solution without requiring extensive technical assistance or downtime.

Lab Prototyping Plug-and-play PID Controllers are a great way to speed up the prototyping process for researchers and engineers who develop new products or processes involving temperature control. The quick setup allows rapid testing of temperature control strategies.

Situations Requiring Rapid Implementation: Plug-and-Play is a great option for any scenario in which a temperature-control system must be quickly installed and functional. It could be for temporary installations, applications based on events, or in situations where systems are being replaced.

6. Choosing the right Plug-and Play PID controller

Although plug-and play simplifies things, it is important to make a careful choice based on the application requirements in order to get optimal performance.

Important Factors for Consideration:

1. Temperature range and accuracy requirements: Determining the temperature range and level of precision required for your particular process. Verify that the controller plug-and play, as well as its sensor and actuator connections (if it is integrated), can work within these parameters. Verify accuracy and resolution.

2. Sensor compatibility (Make sure auto-detection covers your needs ):) Confirm the plug-and play controller's auto-sensing can detect the type of sensor and the range you plan to use. Consult the specifications of the sensor types supported by your manufacturer. Plug-and-play units may not be able to support a particular sensor.

3. Actuator control needs (Heating/Cooling power, type ): Determine the required power (voltage and current), as well as what kind of actuators you'll be controlling. Check that the output terminals of the controller and its power rating match. You must ensure that the output capability of the controller matches the requirements for the actuator if you are connecting it yourself (which may happen if your controller prewires only the sensor).

4. You should consider the connectivity requirements (Local control, remote access, data logging ):) when deciding how to configure and monitor your controller. Are you going to use local controls that are simple? Are you going to use a smartphone application or a remote network connection for adjustments and monitoring? Do you require data logging? Select a controller that suits your requirements and infrastructure.

5. Environmental Specifications: In which locati0n will the controller go? It should have a NEMA rating or IP to ensure it is protected from moisture or dust.

6. Prices of plug-and-play controllers can vary widely. Although they can save time in the installation process and reduce errors, their initial costs may be more than the cost of the basic components. Compare the benefits of the future against your budget.

Compare Plug-and Play Options: Before selecting a model, consider the above features. Search for technical or product comparisons and reviews that describe the performance of each model, its ease of use, as well as specific features. Take into account the support and reputation of the manufacturer.

7. Install, set up, and operate

Installation of plug-and play PID controllers is simple. The specifics of the installation process vary depending on the model. However, it is usually very straightforward.

The Simplest Installation Process: A Conceptual Guide (Step by Step)

Safety first: Always disconnect power from the controller before installing any equipment.

Quick Start Guide: Find and read the quick start guide of your manufacturer.

Connect power: Plug the power cable into the controller power input terminals. Make sure the voltage is in accordance with the specifications specified in the user manual. Check connections twice to ensure they are correct.

Connect Sensor: Attach temperature probes to processes that are being monitored. Connect the sensor cable with the input terminals on the controller. If it's not an integrated sensor, make sure that the cable is connected properly and is compatible. It is likely that the auto-sensing function will detect it upon power up.

Connect Actuator: Connect heating/cooling element (actuator), if it is not already integrated, to designated output terminals on the controller. Verify compatibility with the type of power and requirements.

Turn on the Controller: Plug the power supply into the controller.

Quick Installation: Turn on your controller. Plug-and-play should be enabled. It is possible that the controller will automatically detect and show a setpoint default. You can adjust your desired setpoint temperature using the intuitive interface. Now the system is ready to automatically adjust the actuator when necessary. Basic operations can be observed directly on the display of the controller.

Basic Controls and Understanding User Interface: The interface of most plug-and play controllers is relatively straightforward. You can find options for viewing the temperature and setting the setpoint. Status messages are also displayed. The quick-start guide will provide a thorough explanation of how the controller interface works.

8. Maintaining and basic troubleshooting

Like any other electronic device, plug-and-play controllers require little maintenance. However, they can be helped by basic care, and troubleshooting if problems arise.

Care and Maintenance for Plug and Play Controllers: Inspect the unit regularly for signs of damage or dust buildup (ensure adequate ventilation) and make sure the sensor cable (if applicable), is connected securely and that the actuator functions correctly. Clean and dry the area surrounding the controller.

Addressing common issues (e.g. no response, incorrect readings, sensor/actuator connection challenges): Some of the most common problems include the controller failing to power on (check the power connections), inaccurate temperature readings from the sensors (verify the connection and check for obstructions), actuators not performing as expected (verify that the actuators are powered, verify connections), or error messages displayed by the system. The basic troubleshooting usually involves:

Checking power connection.

Assuring that the sensor has been properly installed and is connected (even when auto-sensing fails).

The actuator connector should be checked.

The interface allows you to review the basic settings and setpoints.

If possible, reset the controller according to the instructions.

You can check for error codes on your interface.

When professional support might be needed: After following the instructions of the manufacturer, performing basic troubleshooting with no success or when the system is complex or involves safety interlocks or critical processes, it's best to engage the technical support from the manufacturer or hire a technician who's qualified for the diagnosis and repair.

The Plug-and Play PID controllers are a major advancement in thermal management. These controllers combine powerful PID capabilities with unprecedented installation ease and quick readiness. They make temperature control more accessible for users who lack technical knowledge or have tight deadlines. Plug-and-play PID Controllers are a great choice for many applications. They can be used in smart home automation, educational projects, small industrial or commercial uses, etc. The plug-and play nature of the controllers makes it easier to achieve reliable thermal control. A plug-and play controller is a great choice for anyone looking for a reliable and simple-to-implement PID system. It offers a good balance between performance and functionality, and stands out as an example of modern engineering.

- Instantaneous precision control with Plug-and Play temperature controllers

- Step-by-Step Guide, PID Tuning, Applications