Precision control explained: How do PID temperature controllers work?

The following is a brief introduction to the topic:

tuning methods, and applications in real life.

2. What is PID controller?

The PID control is an electronic system which continuously calculates the error, i.e. the difference between an desired setpoint and measured process variables (PV), like temperature. The PID controller generates output signals that minimize the error by using three coordinated measures: proportional (P), integral (I), or derivative (D). To achieve stability, PID controllers use modulation of output intensity, such as pulse width modulation, to reduce temperature oscillations. Core components are:

Thermocouple sensor measures actual temperature with a thermocouple.

controller: Calculates error and performs PID algorithm.

Actuator : Thermostatic input for a heater, cooler or valve.

Closed-loop systems allow for real-time adjustment, which is critical to precision-dependent processes.

3. The PID Actions: I, P and D

PID algorithms synthesize three control actions in order to maximize response.

Control proportional (P).

The output is a proportional response to the error. (P = Kpxe). High Kp (gains) can reduce error rapidly, but they also increase the risk of oscillations and overshoot. With P-only controls, steady-state errors (a persistent deviation from the setpoint) are often present.

Integral Control

Eliminates steady-state error by integrating past errors over time (I = Ki x e dt). This method corrects small residual offsets, but if it is not bound can cause an "integral overshoot" or excessive windup.

Derivative (D) Control:

Predicts future errors by using rate of error changes (D = Kd/de/dt). It stabilizes and dampens system oscillations, but increases sensor noise.

4. Operation of the PID in Steps

A PID temperature controller executes four sequential tasks:

Measurement:

Sensors (RTD, for example) sample the temperature and convert it into an electrical signal.

Error calculation

Comparing the value measured with the setpoint.

PID Computation:

The controller uses tuning constants to calculate output (Kp Ki Kd). As an example:

If SP is 100degC but PV is 85degC then e is +15degC.

The P-action is the immediate corrective action (e.g. 80% of heater power).

If the error continues, I-action will add power.

If temperature increases rapidly, reduce power.

Output adjustment

Thermal energy can be modulated by signaling actuators, such as PWM-driven heating systems.

Visualization A graph showing the stability of PID (smooth convergence to setpoint) and P-only (oscillatory).

5. The PID tuning methods

To achieve optimal performance, Kp, Kd, and Ki must be calibrated to the system dynamics.

Manual Tuning

Adjust Kp for rapid response first, followed by Ki to remove residual errors, and Kd, to suppress oscillations.

Ziegler-Nichols Method:

Increase Kp to a point where oscillations are sustained (Ku = gain ultimate).

Measure oscillation time (Tu).

Set Kp = 0.6Ku, Ki = 2Kp/Tu, Kd = KpTu/8.

Auto-Tuning:

For complex systems, modern controllers self-calibrate using step-response testing.

Instability and sluggishness can be caused by poor tuning. Thermal inertia, sensor lag, etc. must all be taken into consideration.

6. Apps

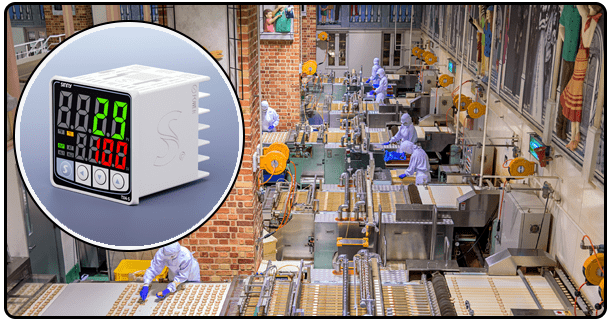

PID controllers enable precision in diverse sectors:

Industrial:

Plastic extrusion (stability of 1°C ensures uniform viscosity).

Reactors with chemical reactions (prevents the thermal runaway).

Consumer Devices

Temperature control for 3D printers' nozzles and beds

Espresso machines (optimal brew temperature).

Energy HVAC Systems balance comfort and efficiency via modulated airflow.

Case study In semiconductor etching PID controllers keep plasma chambers between 200degC and 0.5degC to prevent wafer defects.

7. Benefits and limitations

Advantages:

Near-zero steady-state error.

Adaptability is the ability to adapt dynamic, complex systems.

Energy consumption is reduced compared to on/off controls.

Limitations:

Tuning complex non-linear processes.

Sound sensitivity (D action).

The system's dead time is too long for this product.

Fuzzy logic (MPC or fuzzy logic) is an alternative for nonlinear, highly complex applications.

8. Conclusion

PID temperature controllers remain indispensable for precision thermal management, leveraging proportional, integral, and derivative actions to balance speed, stability, and accuracy. As industries demand tighter tolerances, innovations like AI-driven tuning and IoT-enabled PID systems are enhancing adaptability. Understanding PID principles empowers engineers to optimize processes ranging from laboratory incubators to industrial kilns--ensuring efficiency, safety, and quality in temperature-sensitive applications.

- Precision Temperature Control: West Control Solutions & PID Controllers as Science

- PID controllers: Mastering pressure, level, and temperature control