Temperature Control PID C Code - Implementation Guide for Precision Heat Regulation

Learn the basics of PID temperature controls in C programming. You will learn how to optimize and tune PID algorithms in order to achieve precise heat management for industrial and DIY applications.

Introduction

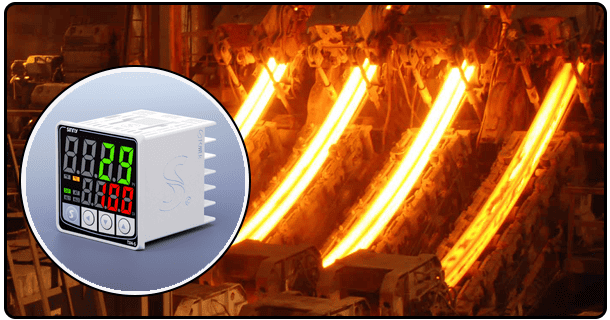

In temperature-sensitive applications, precise regulation of heat is paramount. Maintaining stable temperatures is important for all projects, from industrial automation to DIY. PID (Proportional-Integral-Derivative) control, implemented in C programming, provides a robust solution for achieving accurate temperature control.

The temperature control is crucial in many domains, including HVAC, semiconductor manufacturing and chemical processing. traditional ON/OFF controllers are often inefficient when dealing with temperature variations. However, PID controllers continuously adapt output to current error values. This ensures precise heat regulation.

This guide covers temperature control in C. It includes algorithm structure, optimization methods, applications and SEO strategies to create high-quality content.

2.Understanding PID Control in Temperature Regulation

Basics of PID Control

The algorithm controls temperature by adapting output to changes in heat levels. The algorithm is composed of three components.

Proportional: Responds proportionally to differences between desired temperature and actual temperature.

Integral: Acknowledges past mistakes, and ensures stability with time.

Derived (D): Calculates future deviations in order to avoid overshooting.

PID controllers balance these three parameters to ensure smooth transitions in temperature, reducing abrupt changes and increasing efficiency.

3. On/Off Control vs. PID

PID Controllers are more accurate than On/Off thermostats that simply turn heating elements on and off. They can maintain a consistent temperature by adjusting power gradually.

PID Implementation in C for Temperature Control

Introduction to PID programming in C

The implementation of PID requires accurate coding logic and mathematical calculations. Fundamental steps are:

Define PID Parameter.

Processing input and reading sensor data

Computing PID output using error correction.

Signals for adjusting actuators.

4. Basic Algorithm for PID in C

The PID function is a simple C function that looks something like:

C

double pidControl(double setpoint, double currentTemp) {

static double integral = 0, prevError equals 0.0

double Kp = 2.0, Ki = 0.5, Kd = 1.0;

double error = setpoint - currentTemp;

integral += error;

double derivative = error - prevError;

prevError = error;

return (Kp * error) + (Ki * integral) + (Kd * derivative);}

The function calculates the PID values by processing sensor input, and then adjusting the heating elements according.

Required Components for Temperature Control

Hardware Key Elements

The following components are required to implement PID in C:

Sensors of Temperature: Thermocouples, PT100 sensors.

Microcontrollers: Arduino, STM32, PIC-based controllers.

Actuators : Heating Elements, Cooling Fans

Power Source: Stable Voltage sources to avoid fluctuations

The components play a crucial role in Temperature Stabilization and ensure optimal results.

How to write the PID temperature control code in C

Guide to Step-byStep

Initialize the system variables.

Calculate PID.

Maintain real-time control by optimizing loop execution.

Use external libraries for a more efficient process.

Example C Code for Real-Time Temperature Control

C

#include

Double setpoint = 75.0 ; // Desired Temperature

double pidControl(double currentTemp) {

static double integral = 0, prevError equals 0.0

double Kp = 2.0, Ki = 0.5, Kd = 1.0;

double error = setpoint - currentTemp;

integral += error;

double derivative = error - prevError;

prevError = error;

return (Kp * error) + (Ki * integral) + (Kd * derivative);}

{int main() Int Main()

double currentTemp = 70.0; // Example sensor reading

double output = pidControl(currentTemp);

printf("PID Output: %f\n", output);

return 0;|Return 0}|Return 0}

The code enables temperature control in real time, which ensures consistent heating.

Optimization of PID Parameters to Stability

Fine-Tuning Techniques

The PID tuning ensures smooth and stable operation, without oscillations or overshoots. Typical strategies include:

Manual Tuning: Adjusting I, P and D values in a systematic manner.

Self-Optimization Algorithms .

Reducing overshoot by balancing the proportional and derivative factors

Preventing instability by reducing integral values:

By understanding PID tuning methods, you can improve system response and stability .

Real World Applications

Industrial Usage

PID Temperature Control is used by industries for highly-precision processes.

Semiconductor manufacturing: Assures stable production conditions

Chemical Process: Controlled reaction temperature.

Home Projects and DIY

The PID controller is widely used:

Sous vide cooking: Ensures consistency of food temperature.

Heat beds for 3D printers: Accurate filament heating

Case Studies

Many industries are adopting PID Controllers to reduce costs and improve Temperature Control Efficiency.

Optimization of Temperature Control Code PID Content

SEO strategy is essential to achieving high rankings.

Use keywords like "PID temperature control C", "real-time temperatures regulation" and "C code temperature stability". "

Use bulleted lists and clear headings to structure your content.

External & Internal Links: Refer to authoritative sources when referencing.

Image optimization: Use descriptive alt texts and compression techniques.

Title Tags & Meta description: Create compelling metadata.

Search engine optimization best practices will increase the relevance of search results and drive organic traffic.

PID temperature control in C is an effective technique to achieve stable heat regulation. Understanding principles of PID and integrating efficient C codes can help developers build temperature control systems.

Visit GitHub PID Projects or Technical Guides for more information.

- The Complete Guide to Temperature and Humidity Controllers: Applications & Comprehensive Guide

- SSR PID Temperature Controller – Precision Heat Management Guide