How to Check the temperature controller

1.From the precise temperature control of industrial machinery to all aspects of daily life, thermostats have been integrated into our daily lives. They have created certain value for us, but while creating value, they often come with certain problems.

The core of a thermostat lies in sensing temperature and performing automatic regulation. It involves three dimensions: perception, comparison, and execution. As long as the correct techniques are mastered, most common faults can be avoided, maximizing the effectiveness of the thermostat.

1. key to precise temperature control: perception, comparison, and closed-loop execution. Perception of temperature is the foundation, comparison deviation is the basis, and automatic execution is the key

2.The reason why the temperature controller can maintain stable temperature control lies in the "sensing temperature, comparing deviation, and automatic execution" process.

Let's take a look at the common problems with thermostats and how we have ingeniously solved this series of issues. Follow my footsteps and I'll take you into the Sinny temperature control field

What are the common faults of the temperature controller? Which directions do you know roughly for the investigation?

1. Inaccurate temperature reading: Sensor failure, incorrect equipment calibration

2. The controller shows no change to the set value: it could be a wiring issue or a malfunction of the control panel

3. Temperature exceeding or falling below the upper and lower limits: Incorrect PID parameter Settings or old equipment

4. Large temperature fluctuation range: Control issues and sensor problems

5. Output error: Relay damage

6. There is a difference between the set point and the actual temperature: The controller probe has not been fully immersed in the fluid

7. The equipment stops heating/cooling, overheats or stops working normally

2.Temperature controller diagnosis

1. Preliminary investigation

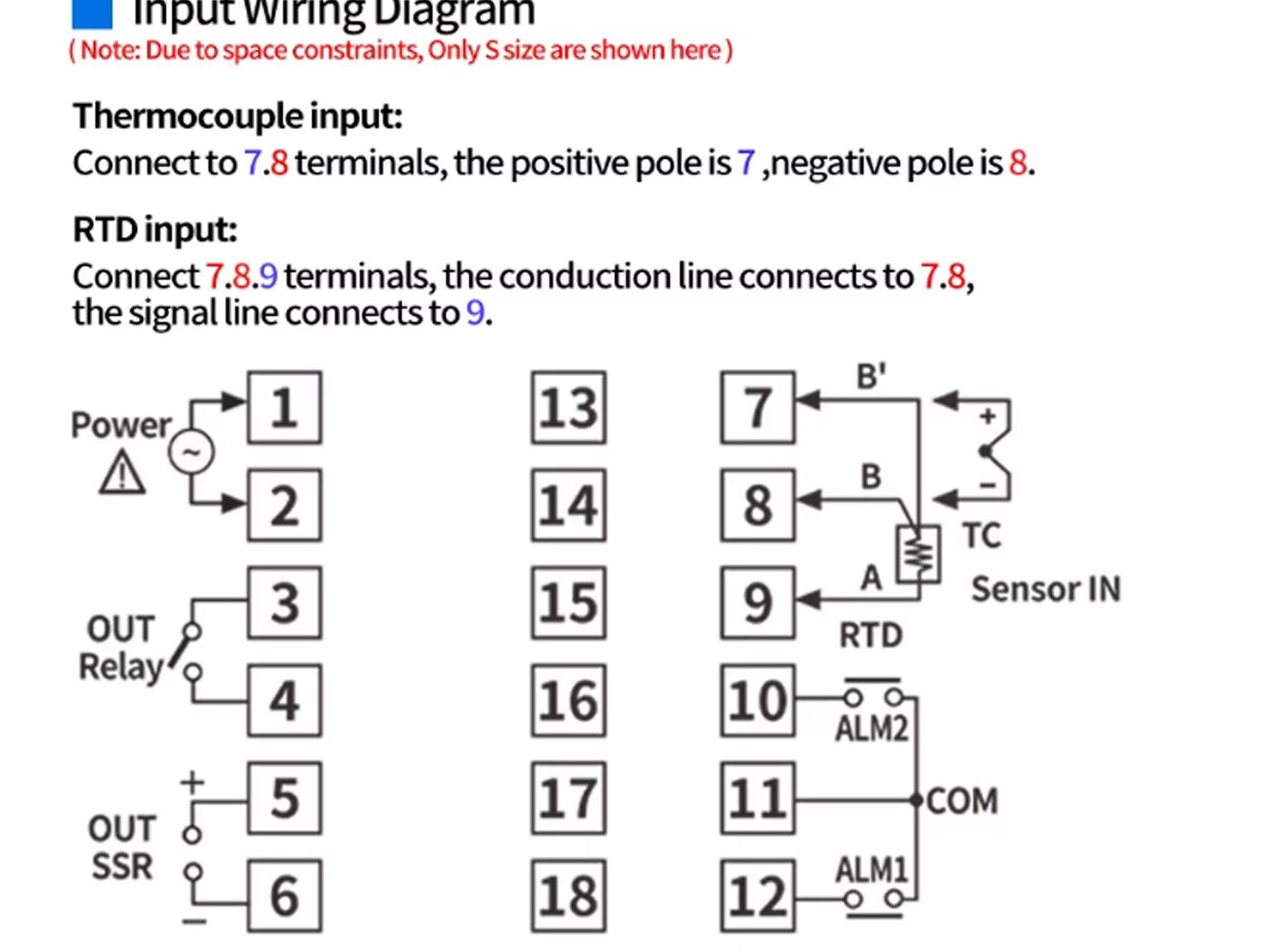

To check the temperature controller, first verify whether the selected input type on the temperature controller matches the sensor you are using and whether the power supply is reasonable. Next, observe whether there are any errors on the display, check whether the lines are correctly connected, and whether the connection points are stable without looseness to ensure the correct reading of data -----. Here, you can refer to the user manual to obtain fault clues

Sensor matching test

1. Confirm the model of the sensor: Generally, there are K E J PT100 CU50. Observe whether the type of sensor that can be connected to the equipment is correct

2. Whether the signal output by the sensor matches the signal received by the device is related to whether the device can accurately identify

3. Wiring issues: The positive and negative poles must not be reversed; otherwise, it will cause a reverse deviation in the reading

Whether the parameters are set correctly: Generally, there are two parameters, PV and SV, for adjustment. Reasonable power supply test: Each type of temperature controller has a certain specific voltage range. The household voltage for general temperature controllers is 220v, while industrial-grade temperature controllers require a voltage of 380v to maintain

Display error code test: Directly observe the screen display and compare it with the initial screen display of the product in the manual

3.temperature controller device issue "What's going on and how to solve it?"

When we have ruled out some simple problems and still cannot find effective solutions, the replacement of components becomes the key to solving the problem

1.When our temperature display reads incorrectly and the actual value does not equal the set value, check if the calibration is accurate and if the sensor is damaged or aged. An aged sensor needle will have a thick layer of oxide, or it may be covered with oil stains, dust, etc. These substances wrap around the needle and isolate the object to be measured, causing inaccurate readings. It could also be that the sensor itself is damaged. Replacing the sensor might be the best option

2. If the control parameters remain unchanged from the set values, it is highly likely that the control panel is damaged. Before doing so, first check if there are any incorrect connections in the internal circuits and if the control panel is fixed. After restoring the temperature controller to its initial state, see if there is any improvement. If there is no improvement, it indicates that the panel is damaged, and replacing the panel is the only solution

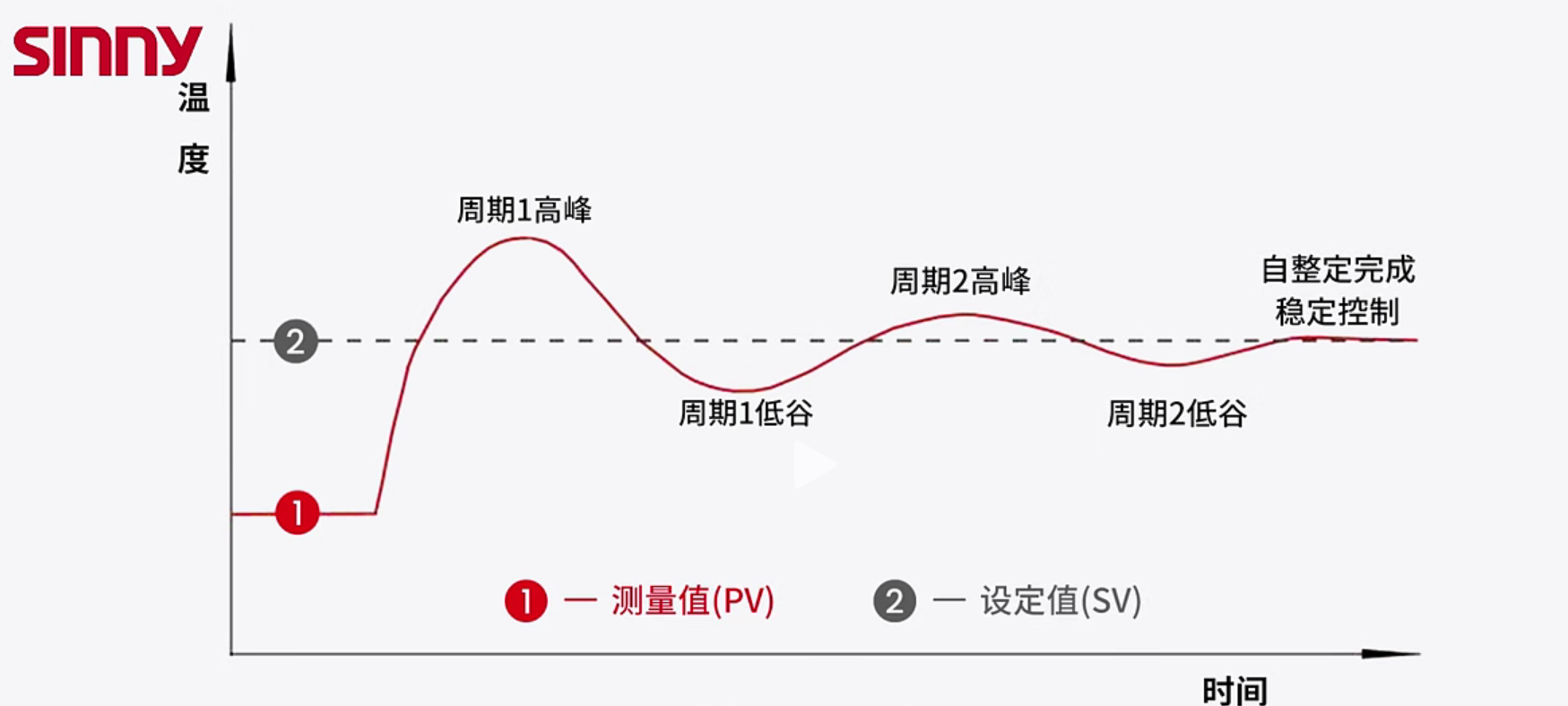

3. If the upper and lower limits of the temperature keep exceeding the standard, first check if the parameters are set correctly and how well the proportional and integral parameters are adjusted. If it is confirmed that there is no problem, it is very likely that the temperature controller itself is broken. It is recommended to replace it with a new one

3. If the upper and lower limits of the temperature keep exceeding the standard, first check if the parameters are set correctly and how well the proportional and integral parameters are adjusted. If it is confirmed that there is no problem, it is very likely that the temperature controller itself is broken. It is recommended to replace it with a new one

4. The temperature fluctuates unstably, which may indicate that the sensor is worn out or the temperature-related components are damaged. It is recommended to replace them with new ones

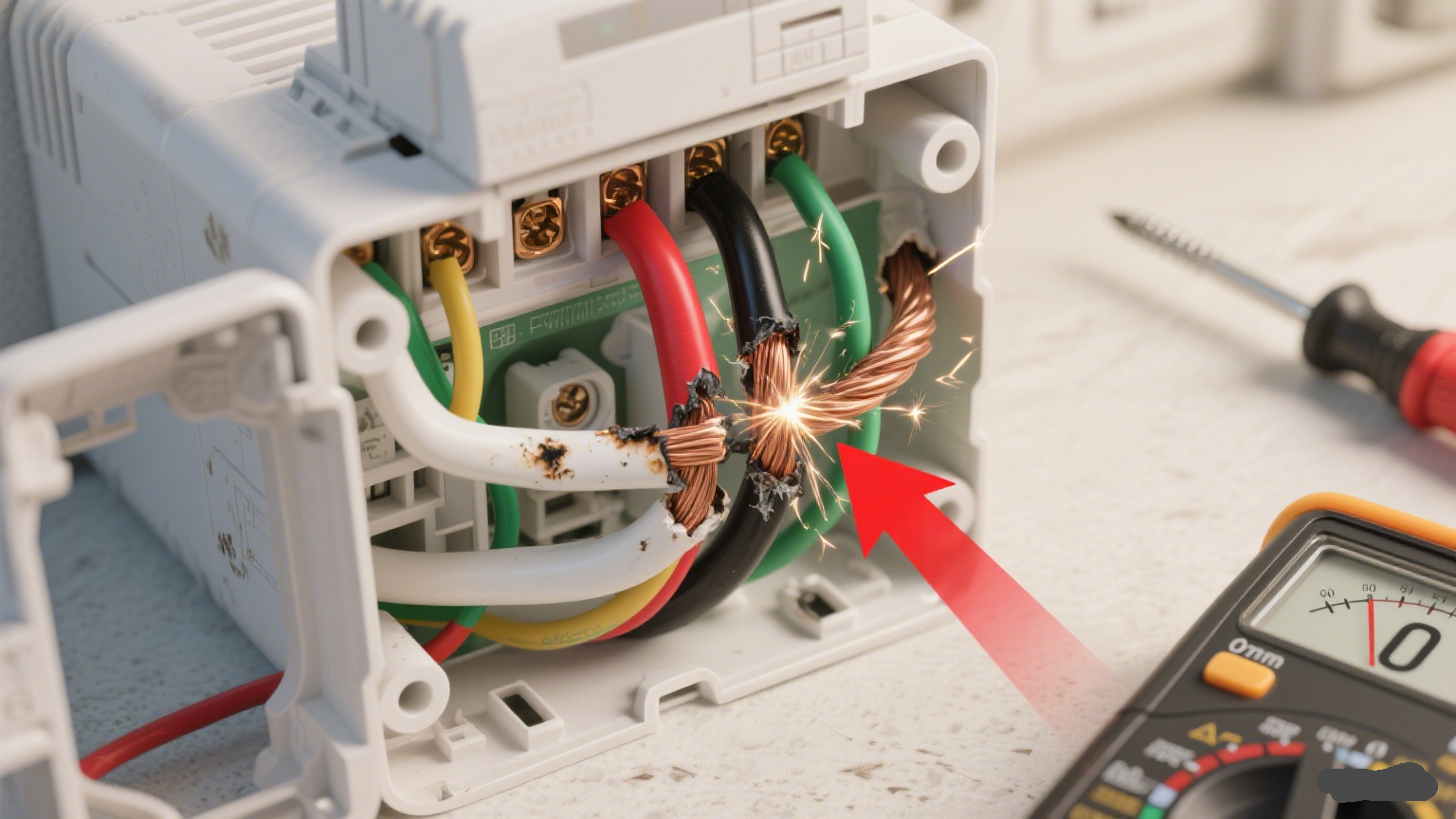

5. Heating and cooling errors are not executed. Relays are generally used to control heating and cooling. It might be that the relay is permanently worn out. Check the fuse and other components. If they are broken, replace them

If you encounter any problems that you can't solve, please contact us

4. Preventive maintenance - Extend the life cycle of the temperature controller

During the operation of the equipment, it is necessary to calibrate the equipment regularly. Long-term operation may be affected by various reasons such as the environment, resulting in poor data accuracy

1. Sensors should be maintained and cleaned regularly to reduce the production of oxide layers that corrode the sensors, avoid affecting their performance, and prevent moisture and dust

2. Terminal blocks: Open the controller housing at regular intervals and reinforce the circuits with a screwdriver.

3. Check if the fuse is in good condition at regular intervals to prevent circuit overload damage

5.Sinny temperature controller ensures your peace of mind when using it

Japanese Chuguang PC plastic material, V-0 flame retardant grade, you don't have to worry about the temperature being too high for the thermostat to handle, -50~1300℃

thermocouples and thermal resistors available on the market are basically supported

Supports temperature unit switching between Fahrenheit and Celsius/Supports Relay output /SSR output switching

powerful PID algorithm automatically cooperates and adjusts to ensure the stability of your upper and lower temperature limits

tapping process in the terminal die significantly reduces the slippage rate, preventing wire slippage and instability, and is highly reliable

With a salt spray test duration of ≥700 hours, it has extremely strong anti-corrosion ability and a long service life

It adopts Taiwan Everlight LED beads, making the digital display softer, clearer, less dazzling, more reliable and durable, and significantly reducing the failure rate such as missing pens

High-configuration components make information transmission more sensitive. The PID algorithm is fast, accurate and powerful, greatly increasing efficiency

- Choose temperature controller. "Fit" is better than "appropriate"!

- process of setting up a pid temperature controller - Problem explanation