Choose temperature controller. "Fit" is better than "appropriate"!

The temperature controller, also known as the thermostat, is needed in everything from industrial production lines to household heating. As long as there is a stable "temperature demand", we all need its assistance. Depending on the different application scenarios, they can generally be divided into industrial fields, commercial fields, and civilian fields. The requirements for controllers in each scenario are not clear. The following is a detailed introduction to s from the aspects of "temperature control accuracy, scene adaptability, energy-saving performance, and stability"

1. The importance of precise temperature control ------ in industrial scenarios, and the error of the temperature controller displays how much the accuracy gap is

We know that the temperature requirements for factory product production are far greater than those for civilian scenarios. Taking the metal industry as an example, the temperature needs to be controlled within ±0.5% to ensure the stability of the reaction. We monitored three different levels of temperature controllers for 12 hours in the metal manufacturing process (0~1300℃)

Traditional thermostat

The most common type is mechanical thermostats, with a temperature range of approximately 0 to 500℃. They operate based on the principle of thermal expansion and contraction, and the measured error has reached ±0.8℃. In industry, as the temperature rises to around 130℃, "overclocking" occurs, and calibration must be carried out at regular intervals; otherwise, the temperature error will continue to increase

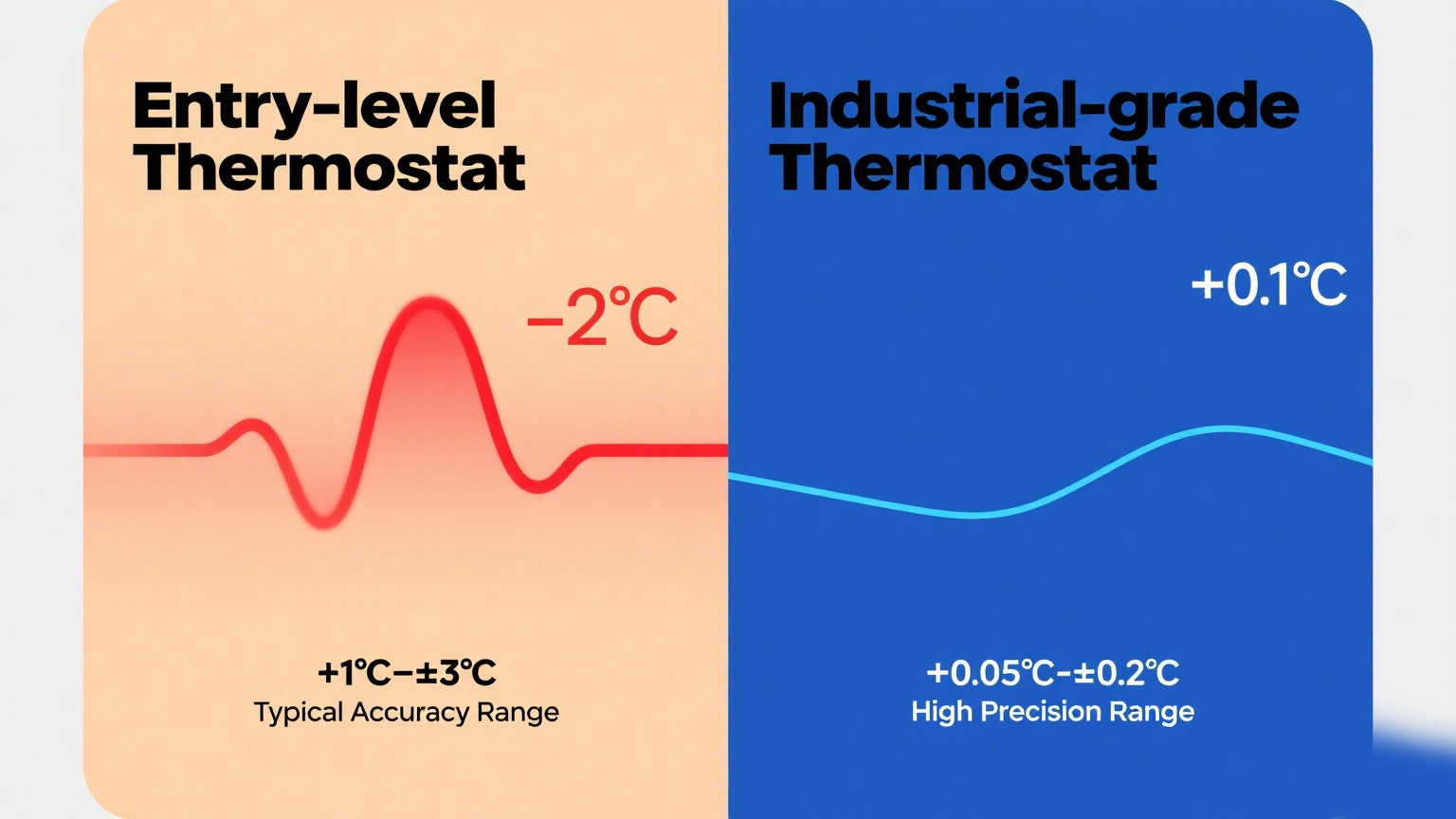

Entry-level temperature control requirements

The general accuracy of this type of thermostat is higher than that of traditional thermostats. The accuracy of this type of thermostat can generally reach ±0.5℃ and ±1℃. The response speed is very slow in the low temperature range of 0 to 100 ℃. It takes about 15 minutes for the set temperature to stabilize, which may lead to incomplete metal smelting. It is generally suitable for environmental temperature control in ordinary mechanical processing workshops and temperature maintenance in general industrial ovens.

Industrial-grade temperature controller

Adopting the "dual sensors +PID self-tuning algorithm", its error is astonishing ±0.1℃, the internal temperature fluctuation does not exceed 0.2℃, and there will be no overclocking problem as the temperature rises. The temperature switching only takes 7 minutes, and the high precision fully meets the requirements

We generally do not use traditional low-quality temperature controllers as they are time-consuming and laborious, and the effect is not very good. We usually only use entry-level and industrial-grade temperature controllers. Generally speaking, entry-level temperature controllers can already meet our normal needs. If you have a working environment in high-temperature conditions and the requirements for precision are very strict, then industrial-grade temperature controllers are your best choice. Of course, Director Wang of a certain factory has also reflected on the impact of using high-precision thermostats on costs.

2. Adaptability of the Temperature controller scenario --------- from heating and cooling temperature

Different industries require different thermostats

Food processing to refrigeration protection From drying to refrigeration, we have tested the performance of the temperature controller in different environments, such as high-temperature baking (180℃) or above, and low-temperature refrigeration (-5℃). The working conditions in different industries vary. When using traditional temperature controllers, due to the increase in temperature, the "overclocking" phenomenon often occurs. Due to the extremely large error, precise temperature control cannot be achieved. If this equipment is to be used, separate wiring is required. Only supports single-device use.

In cases like this, choosing an entry-level or industrial-grade thermostat is your best option. We have a customer who is a thermostat manufacturer for making bread. After choosing our thermostat, he gave us a good review. It's easy to operate and not prone to errors. One thermostat can handle everything. It can also be connected to a mobile phone to view the temperature of different areas. It's a great victory.

3. Energy conservation and stability of Temperature controller ------- industrial large-scale mechanical equipment. The product operates 24 hours a day, with a high failure rate and high power consumption rate

The equipment in factories usually operates non-stop throughout the year, so the energy efficiency of the products is related to the electricity cost. Moreover, the failure rate of the products does indeed affect the operation and shutdown of the production line

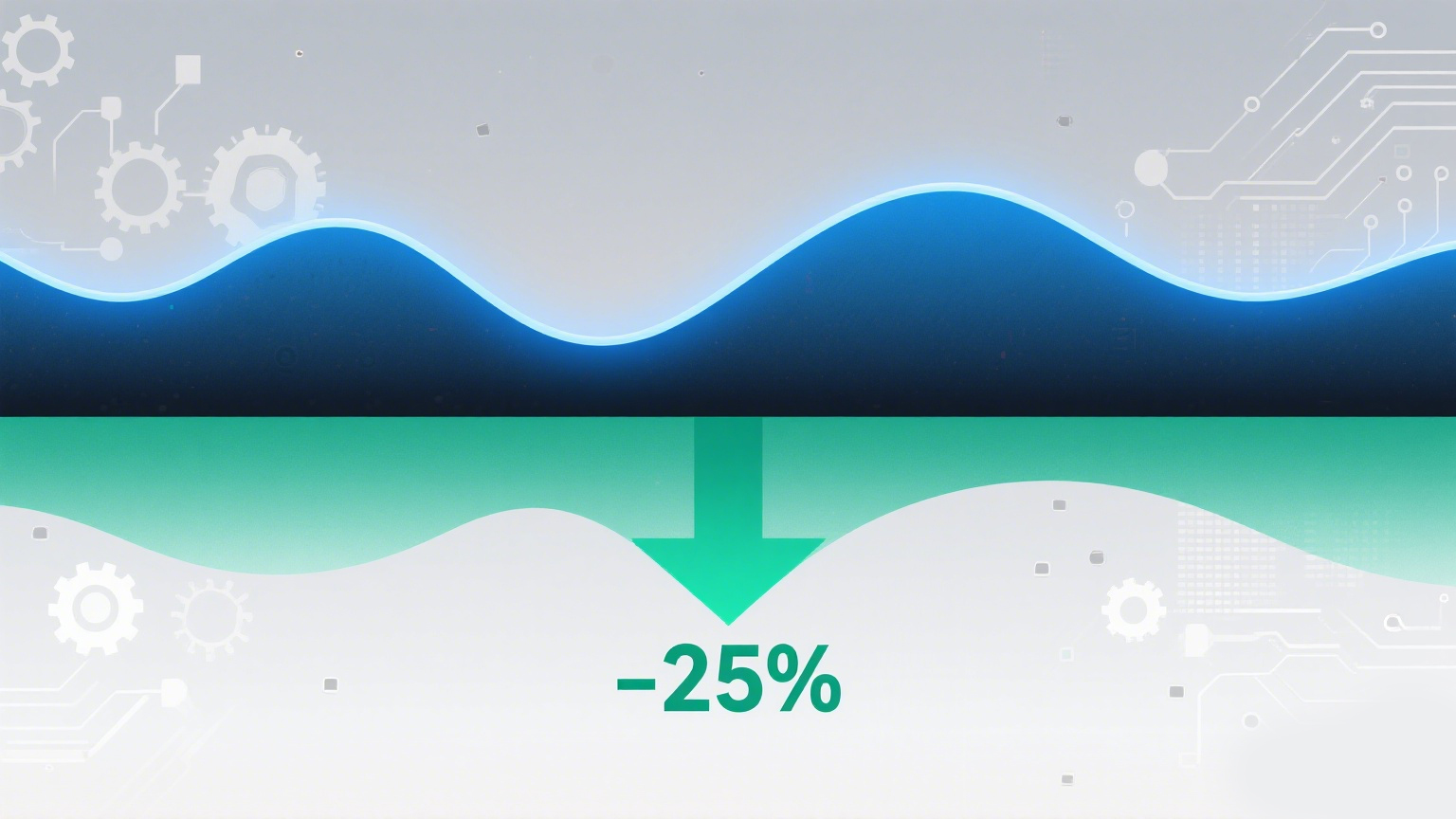

Energy conservation: The more advanced the thermostat is, the more electricity it consumes. This is because high-end thermostats feature dual chips and advanced PID algorithms, and their efficiency is often N times that of ordinary thermostats

Fault: Here's a point to mention: High-end thermostats have the function of self-diagnosing faults, and hardware faults are very rare. Don't be bothered by the trouble and choose low-end thermostats, as it will indirectly increase your time and labor costs.

4. How do different industries choose thermostats?

In industrial fields with high stability requirements: There is no doubt that industrial-grade temperature controllers should be chosen, featuring self-diagnosis, backup sensors, and PID algorithms

2. Multi-scenario requirements (pharmaceutical, chemical, packaging machinery, food, etc.) : Choosing our sinny temperature controller is your best choice. All services are in place, with an accuracy of ±0.5℃, a temperature control range of -50 to 1300℃, support for multiple types of input and output, advanced chip temperature control +PID self-tuning algorithm, allowing you to free your hands

3. High-precision demand industries: It is recommended that you steadily select the corresponding temperature controller based on your precision requirements. Generally, it is advisable to choose those with PID self-tuning algorithms. Our sinny temperature controller is also a good choice

5. Choosing "reliable" is more important than "cheap"

For factories, some low-quality thermostats often cause production stops on the assembly line due to inaccurate temperature control or loss of control. The products produced have poor temperature control and become substandard, resulting in a loss of tens of thousands or even hundreds of thousands of yuan in costs. Although low-quality thermostats seem to save costs, they actually cause huge losses, such as Production line shutdowns, high scrap rates of thermostats, inadequate food baking, inaccurate temperatures, frequent malfunctions, excessively high electricity bills, and too low temperature ranges are all hidden time costs.

We are a technology-oriented enterprise specializing in the research and development and production of industrial automation process measurement and control components. If you have any of the above questions, feel free to contact us for a free evaluation ----- take you to "sinny temperature Control manager"