A Guide to Tuning PID loops for Temperature Control

I. I. Introduction: PID tuning in temperature control

Process Control Engineering is a key component of industrial systems today, as it ensures that they operate safely and efficiently. Among the most ubiquitous control strategies is the Proportional-Integral-Derivative (PID) controller. The effectiveness of PID controllers in managing dynamic processes has been widely recognized. Although PID controllers can be used in many different domains, the implementation of these devices for temperature control presents unique opportunities and challenges. In many applications, such as chemical manufacturing, material processing, environmental chambers, heating, ventilation and air conditioning systems, maintaining precise and constant temperatures is essential. The PID loop must be tuned properly to achieve the performance desired - quick response, minimum overshoot and tight control of the setpoint. A temperature control system that is not tuned properly may show instability, low accuracy and slow behaviour. This can lead to reduced efficiency, decreased product quality and safety risks. The purpose of this article is to present a guide for tuning PID circuits, specifically designed to control temperature. It draws on established process engineering principles.

II. The Basics of PID Systems and Temperature Control

The PID controller calculates an error value which is the difference in the Setpoint (SP), the setpoint desired, and the Process Variable measured by the sensor. The controller then takes a correction based on the following three terms:

Proportional: Controller output is proportional with the error. The output will change more if the error is larger. The proportional approach helps reduce error, but leaves an offset at steady state.

Integral: The output of the controller is corrected based on a cumulative sum over time. The steady state offset is eliminated by this term, which continuously corrects the output to zero.

Derived (D): Controller output is affected by rate of error change. The controller predicts errors in the future based on current trends, which helps to improve stability and dampen oscillations, thus speeding the response.

A sensor, such as a thermistor, RTD, or thermocouple (as an example), measures the temperature of the loop (PV). The PID controller compares this measurement to the setpoint temperature (SP). This controller generates a signal based on the calculated error. The output signal is usually used to drive an actuator. This could be a heater, cooling coil, valve that controls a refrigerant's flow or any other device capable of changing the thermal conditions in the system to bring the SP closer to PV.

The temperature sensor, the controller (often a part of a Programmable Logic Controller or Distributed Control Systems (DCS), the actuator, and the control process (e.g. the reactor or ovenQiang) are all key components in this loop. Effective tuning requires an understanding of the interactions between each component. Tuning strategies are influenced by the different temperature control applications, which require varying degrees of precision and speed.

III. What is the importance of tuning for optimal temperature control?

A PID system must be tuned correctly to perform optimally and meet the intended needs of a temperature-control system. Poorly tuned PID loops can exhibit several negative behaviors. An overshoot is when the temperature of the system exceeds its setpoint, before it stabilizes. This can damage sensitive materials and cause safety concerns. Instability manifests as a temperature fluctuating around the setpoint. This makes the system difficult to control and unpredictable. A slow response or long settling times means that the system is taking too much time to maintain and reach the temperature setpoint after a change. This leads to reduced efficiency and throughput. steady state error or offset refers to the temperature difference between final and setpoint temperatures. This indicates that the integral term is not performing well.

It is the primary objective of PID to set up the gains so that the loop achieves an ideal balance. The loop should be able to respond rapidly to any changes in the system, to settle near the setpoint, with little overshoot or oscillation and to accurately track the setpoint, even when there are minor errors with the sensors, such as a load change. The tuning process is often neglected, resulting in poor performance. This can lead to significant operational and economic consequences.

IV. Common tuning methods for temperature loops using PID

There are many ways to tune PID controllers. These range from simple empirical methods to sophisticated, modern approaches. The selection of the method depends on many factors, including the complexity of the systems, the available tools and the expertise of the engineers.

A. A.

Since decades, these methods have relied on the empirical observation of process responses.

Ziegler Nichols Method: Probably the most popular manual tuning method. This method is a systematized way of determining initial PID gain based on a process's response to frequency. This procedure usually involves two stages:

Open Loop Method: Integral and derivative actions of the controller are disabled (set at zero). The controller's output is changed in a step-wise manner (usually while the system has reached steady state). This is done by identifying the ultimate gain (Ku), which represents the maximum gain that the system can achieve before it exhibits oscillations. Then, the ultimate period (Tu), or the duration of the oscillations (the period), are determined. Ziegler & Nichols provide empirical formulas that can calculate approximate PID gain (Kp) using these values. As an example, Kp could be set to 0.6* Ku with integral time Ti equaling 0.5* Tu. It is important to note that these rules can be applied directly for temperature loops that have significant dead times.

Step-Response Method: A second alternative is to apply a step change directly to the variable in the process (if safe and possible) and observe the response of the system. The step curve is used to estimate parameters such as the process gain Kp, the time constant T and the dead-time L. Ziegler and Nichols formulas are again applicable to derive the initial gains from these estimations. The response must be carefully interpreted to use this method.

Ziegler-Nichols is a good starting point. However, the gains that result often require further refining through trial and error or by watching the closed loop response.

Method of Critical Point: In this method, the critical point is determined by finding the gain where the system stops oscillating and becomes stable. Then, the formula used to calculate PID parameters can be applied. In many applications in real life, such as complex temperature control systems, it is considered to be less robust and practical than Ziegler's-Nichols.

B. B. Modern/Advanced tuning methods:

Tuning techniques have evolved along with control theory and computer power.

Tuning Software: The majority of modern Distributed Control Systems and Programmable Logic Controllers have auto-tuning features built in. They follow a similar procedure to open-loop but they are automatized. These tools apply small signals to the process, measure its response, calculate key parameters of the process (such as gain and dead-time), and determine suitable gains for PID. The tuning effort and time required is significantly reduced, particularly for those operators who are less familiar with manual tuning.

Frequency response analysis: The method consists of analysing the frequency response characteristics of a system (often by using Bode plots and Nyquist graphs) in order to calculate suitable PID gain. This method requires more advanced knowledge of control theory, but it can give a better understanding of system dynamics.

Tuning based on a model: The approach involves developing a mathematical representation of the process for temperature control. You can use techniques like Linear Parameter-Varying or Non-Linear Model Predictive Control. Advanced software can be used to calculate the optimal PID gain based on a model's performance and other criteria. The model-based tuning method is accurate, but it can also be complicated and require a lot of effort to develop.

Tuning Based on Optimization: The optimization-based tuning method is a technique that involves setting up a list of performance criteria, such as minimising overshoot and settling times, or minimizing integral absolute errors, then using algorithms to determine the gains in PIDs which best satisfy these criteria. It can be done either offline by using simulation models, or online by making gains adjustments based on the real-time feedback.

The decision between the two methods is based on the complexity of the system, available tuning tools and required performance level. Software-based autotuning, or manual fine-tuning based on Ziegler Nichols principles is often the best option for many temperature control standard applications.

No matter which method is chosen, effective PID tuning follows a systematized approach. Preparation and careful observation are essential.

A. Preparation:

It is important to define and understand the performance desired before tuning a PID. It is important to identify the time constants of the process (how fast the temperature changes in response to the controller), the dead time between the controller and temperature change, and the ultimate characteristics of the system. Define the performance criteria: How quickly the system should respond to changes in the setpoint (settling time), what is the acceptable level of overshoot, and how large is the steady state error? It is important to evaluate and guide the process of tuning. This stage also includes selecting the best tuning technique based on tools available and expert knowledge.

B. B.

Tuning involves adjusting P, D, and I gains iteratively while watching the response of the system.

Initial gain selection: The majority of tuning strategies start with a small proportional gain. It is important that the system be stable to allow you to monitor its response. It is important to select a gain that will cause the system's response to be significant, but not too high to make it unstable or to oscillate excessively when a slight disturbance occurs. This initial phase will be handled by software if you are using auto-tuning.

Only adjust proportional gains (P). Set integral and derivative gains to zero or their default value if auto-tuning is used. Increase the proportional gain in increments. Watch the response of the system to any changes in setpoint. It is important to select a gain which provides an adequate response time without creating significant oscillations. Nota: the steady-state offset (error) is shown. The initial gain P serves as a point of departure.

Integral action (I): Incorporate integral action (I), by gradually increasing integral gain. Integral term's primary goal is to eliminate steady-state errors. Integral windup can occur if the integral gain is increased too quickly. The controller will integrate the error for a very long time, which can cause the output of the controller to reach its limit (maximum or minimum) before the error is corrected. Reduce the integral gain. If output becomes saturated or unstable, increase integral time. Many modern controllers have features that prevent or reduce integral windup. Watch how the system settles. Aim for a minimal offset and acceptable stability.

Derivative Action (D): Incorporate derivative action (or derivative timing, Td) by carefully adjusting derivative gain. This derivative term can help predict errors in the future based on rate of change. It also helps improve response time by dampening oscillations. The derivative term can increase noise coming from temperature sensors, which could cause the output of the controller to fluctuate. Modern controllers often include derivative filters that smooth out the input of derivative terms, thus reducing noise. Begin with a low derivative gain or a large derivative time and see the effects. If oscillations occur, increase it slowly. Be careful not to cause noise or instability.

Final tuning: After achieving a stable basic response, continue to iterate the gains in P, I and D. Often, small adjustments will improve performance. For instance, increasing P could speed up response time but also increase overshoot. Adjusting I would eliminate the offset while slowing things down. It is important to achieve the right balance between performance and cost. If available, use graphical tools such as Bode plots and Root Locus Diagrams (more sophisticated) or simpler methods, like bump tests (adding small disturbances to the setting or making deliberate, small changes) to further refine gains. Tuning is an ongoing cycle of adjustments and observations.

C. C. Monitoring and Adjustment

The performance of the loop PID should be checked under different conditions after initial tuning. What is the response of the system to changes in load, like variations in temperature or demand? What is its response to sensor noise and minor fluctuations? To ensure robust performance in different operating situations, fine-tuning is often required. Model Predictive Control techniques (MPC) are advanced methods that can account for disruptions, optimize performance and provide a longer prediction period. They add another level of sophistication to complex temperature loops.

D. Safety must always come first. Set gains to avoid dangerous oscillations, overshoots that can damage processes, and actuator saturations that cause stress on equipment. Follow safety procedures and emergency shut-down protocols.

E. Implementation: After determining satisfactory gains through simulations or offline tests (if this is possible), incorporate them into the control system in real time. Monitor closely the loop during its initial operation and make any necessary adjustments.

VI. Temperature Control Systems: Special considerations

The temperature control system can present a unique challenge that may affect the tuning of the device and requires specific considerations.

Time delays: There can be delays in sensor responses, actuator effects on processes, or heat transfer within a system. Ziegler and Nichols formulas may require empirical adjustment, especially for systems that have dead time. Dead time is often best handled with software tuning tools.

Nonlinearity: There is rarely a perfect linear relationship between controller outputs (e.g. heater power) and temperature changes. It is possible that the system will respond differently when temperatures are low or high. For highly nonlinear systems, advanced tuning methods and piecewise linearisation may be needed.

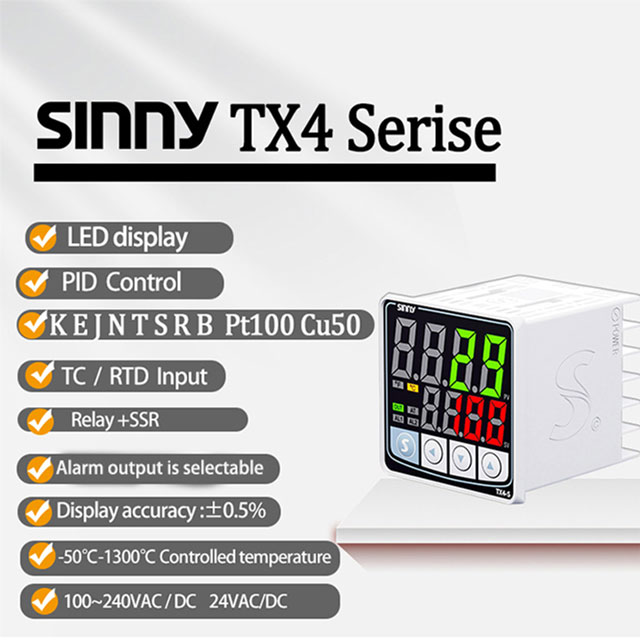

- Digital PID temperature controller: High precision control

- A Guide to Reducing Overshoot on PID Controls