Digital PID temperature controller: High precision control

1. Introduction: Evolution of digital PID controllers and their necessity in temperature regulation

The temperature is a key physical parameter that governs many processes in countless industries. Maintaining optimal temperatures is essential for a variety of applications, from pharmaceutical synthesis conditions to a comfortable commercial climate. Accurate temperature control isn't just beneficial, it can be a requirement for safety, regulatory compliance, process efficiency and product quality. The 4-digit PID digital temperature controller is examined in this article, including its advantages and architecture.

2. At its heart, a basic temperature control system is made up of several components that work together.

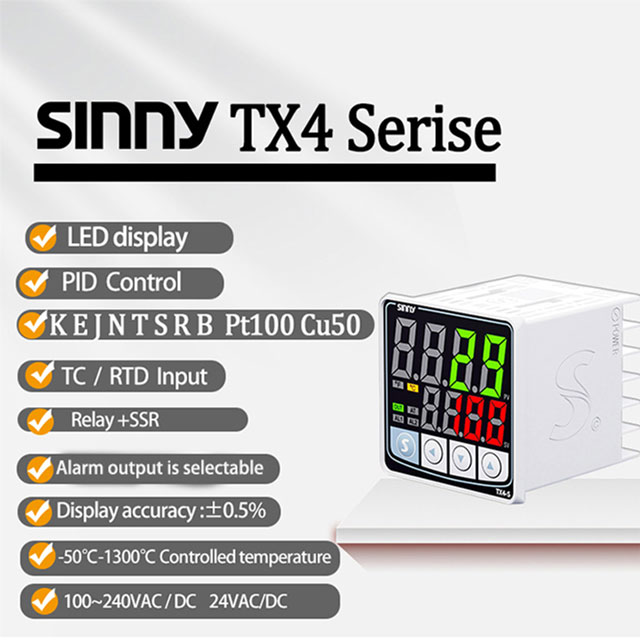

The sensor is the first component. Its primary purpose is to determine the temperature in the process. This is done by the process variable (PV),. The most common temperature sensors are thermocouples (also known as resistance temperature detectors or RTDs), thermistors and thermistors. Each of these has different ranges, accuracy and response times. The controller is used to process the measurement. The controller then compares this measured PV with a target temperature that has been predefined - the Setpoint (SP).. The error is calculated by comparing the measured PV to the predefined target temperature - strong>setpoint (SP)/strong>. This error is processed by the controller using a sophisticated algorithm based on PID. The calculated output signal is used to control the actuator. This device can physically influence the process in order to bring the temperature closer towards the setpoint. The most common actuators used in temperature control are heating coils, cooling coils and fans. The process is what determines the temperature of the system, whether it's an oven, reactor or room. This process is controlled by the actuator, while the sensor monitors the temperature. The feedback loop closes and allows for constant adjustment and feedback. Manual control is simple for small tasks but its limits become evident in more complex applications. The human operator lacks the precision and speed required to maintain stable temperatures in dynamic environments or under tight specifications. Also, they can become tired and make mistakes. Automation, especially using PID controllers overcomes this limitation by offering a repeatable and systematic method of achieving and maintaining desired setpoints.

3. By considering the time-dependent error, the PID controller is arguably the most common

controller used in industrial process controls. It calculates an output to move the process variable toward the setpoint. PID calculates an out put signal to push the process variable toward the setpoint. PID calculates an out put signal to move the process variable toward the setpoint. PID calculates a signal to be used as a driving force for the process variable by taking into account the time-based error. PID calculates an out put signal to move the process variable toward the setpoint. PID calculates a signal to be used as a driving force for the process variable by taking into account the time-based error. PID calculates an out put signal to move the process variable toward the setpoint. PID calculates an out put signal to move the process variable toward the setpoint. PID calculates an out put signal to move the process variable toward the setpoint. PID calculates a signal to be used as a driving force for the process variable by taking into account the time-based error. PID calculates an out put signal to move the process variable toward the setpoint. PID calculates a signal to be used as a driving force for the process variable by taking into account the time-based error. PID calculates an out put signal to move the process variable toward the setpoint. PID calculates a signal to be used as a driving force for the process variable by taking into account the time-based error. PID calculates a signal to be used as a driving force for the process variable by taking into account the time-based error. PID calculates an out put signal to move the process variable toward the setpoint. PID calculates an out put signal to move the process variable toward the setpoint. PID calculates a signal to be used as a driving force for the process variable by taking into account the time-based error. By considering the time-dependent error, the PID algorithm generates an output that is intended to move the process variable toward the setpoint.

- Theoretical Control of Temperature Using PID Controller Theory

- A Guide to Tuning PID loops for Temperature Control