Temperature Control Using PID Controller: Circuit Diagram & Explanation

I. I. Introduction

Temperature control accuracy is a requirement for countless applications in many different sectors. The ability to accurately regulate temperature is essential for a wide range of applications, from maintaining optimal conditions within industrial manufacturing processes to data centres and ensuring stability in laboratory environments to the comfort and safety of residential areas. A poor temperature control can result in a reduced product quality, damaged equipment, excessive energy use, and compromised experiment results. Among the most effective and widely employed methods for achieving sophisticated temperature control is Proportional-Integral-Derivative (PID) control. The technique is a reliable way to maintain a variable in a system, like temperature, within a set point value. The purpose of this article is to explain the basic principles of PID as they are applied to temperature control and provide a detailed circuit diagram that highlights the main components and interconnections.

II. Understanding PID Control for Temperature

A. What is PID Control (Programmable Integrated Device Control)?

PID control, standing for Proportional-Integral-Derivative, represents a fundamental and highly prevalent form of feedback control loop. A control loop is composed of interconnected components that work together to adjust a variable to match the predetermined setpoint. This loop is controlled by the PID controller, which calculates the corrective actions based on deviations between actual variables and desired values. In the context of temperature control, the primary goal of PID is to reduce this error. This will allow for a rapid reaction to any disturbances and achieve and maintain the desired temperature.

B. The three components (P, I and D ):

PID's effectiveness is due to its three interconnected but distinct components that each address different aspects of error in time. It is important to understand these components in order to fully appreciate how PID regulates temperature.

1. The term Proportional generates a signal directly proportional with the magnitude of error. In this context, the error is the difference between desired setpoint temperatures and actual measured temperatures by the sensor. If e(t), the time-dependent error, is defined mathematically as 'P = Kp* e(t), 'Kp,' the gain constant, can then be used to calculate the output proportional 'P. The proportional output increases with a greater error, and vice-versa. The immediate reaction helps initiate correction and bring the temperature of the system closer to setpoint. If you rely solely on the proportional response, it can lead to a steady state error. This is a residual error that remains even after the system has stabilized. The output of the controller will not be enough to eliminate the error completely, but only large enough for the correction. Increased proportional gain can reduce this error, but if it is set too high may cause instability or oscillations.

2. Integral (I ):

Integral terms can eliminate the error at steady state that cannot be eliminated by proportional terms alone. The integral term integrates continuously and calculates the sum cumulative of the error. Integral outputs 'I,' are usually proportional to integral of error for a given time interval. This is often written as I = Ki* e(t), dt where 'Ki,' is integral gain constant. The integral gain term will accumulate if the error continues for any length of time. This corrective action pushes the system closer to the setpoint. The steady-state errors are essentially 'eliminated' over time by this action, which ensures that system temperatures eventually reach the desired values. The integral term is slow-reacting and can contribute to an overshoot when not tuned properly.

3. Derivative (D):

The derivative term is concerned with the rate at which the error changes. The time derivative is calculated, and based on the current error rate it can predict the trend in the future. D is usually proportional to error rate change, and is expressed by D = Kd* de(t/dt), where "Kd" is derivative gain constant. The derivative component can be very useful for improving the stability and stopping oscillations and overshoot. The derivative term, by adjusting to the slope, can take corrective action prior to becoming too large. This dampens the response of the system and ensures a faster, more stable convergence towards the setpoint. This is a type of Yu Jian Xing control (anticipatory), which helps to smooth the temperature changes.

C. The Control Loop

A PID system operates within a feedback loop. The typical sequence is: A sensor measures the temperature accurately within the system. The sensor transforms physical temperature to an electrical signal. This is often voltage or resistance changes. Signals from sensors are fed to the PID control. The measured temperature (Process variable or PV) in the controller is compared to the setpoint temperature (SP) entered by the user. This difference is the error. (E = PV - SP). PID controllers calculate the P, D, and I terms using this error history. This summation of the three terms produces the final output control signal. The output signal sent by the controller is then transmitted to the actuator. This is a device that can physically influence the temperature of the system (e.g. switching on or off a heater, changing the speed of cooling fans). Actuator action changes the temperature of the system. The loop measures the change in temperature and adjusts the actuator accordingly.

III. Diagram of the Temperature Control Circuit

A. Overview:

Circuit diagrams are graphical representations of electronic components in a PID system. They show the signal paths and functional connections. The circuit diagram is a blueprint that helps to understand how all the elements interact in order to reach the temperature control desired. The specific implementation may vary depending on which components are used (e.g. a PID analog controller vs. a microcontroller), but the basic structure is the same.

B. Key Components:

Circuit diagrams typically include several components that each play a role in controlling the process.

1. The temperature sensor is essential for the determination of current system status. The most common types are thermocouples (RTDs) and Negative Temperature Coefficient thermistors (NTC). Thermocouples produce a voltage change proportional to the temperature. RTDs change resistance with temperature. And thermistors show a large resistance change. The selection of sensor is based on temperature ranges, accuracy and environmental conditions. Signal conditioning is required because the output from the sensor cannot be directly used by the PID control.

2. The Signal Conditioning Circuit is a crucial intermediate step that prepares the output signal of the sensor for the PID controller. Raw signals from sensors like thermocouples and thermistors may be weak, nonlinear or outside of a normal voltage/current range. Signal conditioning circuits perform necessary functions such as signal amplification (converting the sensor's response from non-linear to linear with temperature), noise filtering, and possibly signal conversion (from voltage to current, or vice versa). A lookup table, digital conversion, or an operational amplifier circuit could be used to achieve linearization. The signal is then presented in an accurate, stable and compatible format to the PID control.

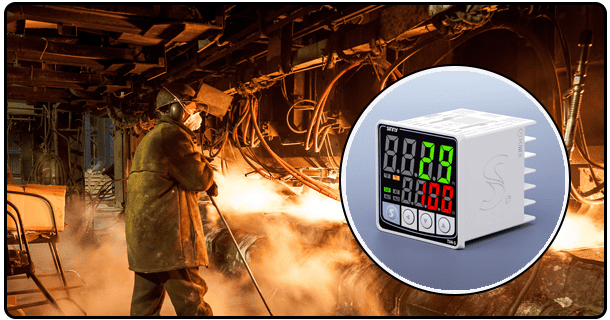

3. PID Controller Unit (also known as PID Controller Unit): The brain of the system that performs the calculations. PID units can be implemented using different methods. One common method is to use a microcontroller equipped with software libraries (such as Arduino, Raspberry Pi or specialized PLCs) in order to implement the PID algorithm. There are also standalone analog PID control ICs that integrate all the required operational amplifiers, circuitry, and other components. The controller is given the sensor's conditioned signal (which represents the PV or Process Variable) as well as the setpoint temperature that the user has defined. The controller calculates proportional integral and derivative terms using the error and its accumulated history (E = PV - SP). Final control outputs are typically voltage signals (e.g. within the range 0-5V, 0-10V, or 4-20mA) or current signals (e.g. between 0-20mA, and 4-20mA).

4. Actuator : An actuator is a device that translates an electrical signal sent by the PID control into physical actions which affect the temperature of the system. Actuator selection is based on application. Solid-state relays are used to switch heating elements and cooling loads. Motor-driven fans can also be used for forced-air cooling. Solenoid valves control fluid flow for heating/cooling system. The actuator is the device that receives and executes commands. It can heat, cool, or modify the temperature.

5. The circuit must have a reliable and sufficient power supply. Power supply: The unit transforms the main voltage (e.g. AC 230V), into low-voltage DC (e.g. +5V (or +12V or -12V), for sensor, signal conditioning, controller PID, and possibly user interface components.

6. A user interface (optional but common ):) is usually incorporated to facilitate monitoring and operation. It usually includes elements such as a display, e.g. an LCD screen, that shows the temperature and setpoint as well as the system status. Input devices, like potentiometers, allow the user to manually adjust the PID parameters.

C. Diagram explanation:

Imagine a diagram.

These components can be represented visually in a simplified block diagram. The main blocks of the system would be represented by rectangular boxes: Temperature Sensors, Signal Conditioning Circuits, PID Controllers, Actuators, and Power Supplies. Arrows indicate signal direction. The sensor, for example, would display an arrow that pointed towards the conditioning circuit. A PID controller would receive an arrow from the conditioning circuit, labeled "Process variable (PV). Setpoint input will also be a arrow that enters the PID Controller, labeled "Setpoint" PID Controller would then send out an arrow towards the actuator, labeled "Control Output". Actuator will then show an arrow indicating its impact on "Process", (the controlled environment), and this will feed back to Temperature Sensor, closing the loop. Power Supply arrows would connect to the required blocks. The feedback system is clearly shown in this visual.

D. Optional ):

Take a look at a simple way to control the water temperature in a tank by using a heater element. Temperature is measured by a temperature sensor, such as an RTD submerged in water. The RTD signal is then sent to the signal conditioning circuit, which linearizes and converts this signal to a voltage of 0-5V. The conditioned voltage is sent to the PID controller along with the setpoint voltage defined by the user. This controller will calculate the outputs P, I and D. The PID output will increase if the water temperature is low (Error > 0,) and a Solid State Relay can be activated. SSR activates heating element to heat water. Sensors measure the increased temperature of the water, resulting in a lower error that is processed by the PID controller. The PID controller reduces the output when the water temperature reaches a setpoint. This results in a zero or near-zero error.

IV. The Circuit (Step by Step)

As shown in the circuit diagram below, the operation of the system can be explained by a series of steps:

Measurement of Temperature: A temperature sensor constantly monitors the temperatures in the system (e.g. the air inside a room or the liquid within a tank). The sensor generates an electric signal that corresponds to the measured temperature.

Circuit for Signal Conditioning: The raw sensor signal is sent through this circuit. This circuit linearizes the response of the sensor to guarantee a direct relation with the true temperature. It also filters any electrical noise and transforms the output into a standard format that can be used by the PID controller (e.g. a 0-5VDC voltage).

Calculate error: Input the conditioned temperature, which represents the PV (Process Variable), into the PID Controller. The user's desired temperature (the Setpoint) is simultaneously inputted into the PID controller. The error (E), calculated by the controller, is the difference between Setpoint and Process Variable.

Calculation of PID: This error is immediately processed by the PID controller using its own algorithms. The PID controller calculates the Proportional Term based upon the current error. It then integrates this error in time, addressing any persistent off-set (the Integral Term), before calculating a derivative term that is based upon the rate of change. The final output control signal is produced by combining these three components.

Generation of Control Signal: This control signal is generated using the PID algorithm and sent by the controller to an actuator. The output signal is typically within a certain range (0-5V), and indicates the desired degree of heating, cooling or another action.

Action of the Actuator: Receives the signal. The actuator will activate the heater if the signal is indicating a temperature increase (e.g. a positive voltage). The actuator may activate the cooling fan or turn off the heater if the signal is indicating a decrease in temperature.

Adjustment of Temperature: Action taken by the actuator has a direct influence on the process temperature. The system is heated or cooled.

Loop of Feedback: After the action by the actuator, the temperature sensor will measure the temperature. The updated Process Variable is based on this new measurement.

Repetition: This sensor will send this new temperature reading to the PID control circuit, and if needed to the signal conditioning system. On the basis of the updated information, the controller calculates the error E = SP – PV and adjusts the output control. Actuator receives new signal of control and adapts action. The cycle of measuring, calculating, acting, and receiving feedback is repeated continuously. This allows the system to respond dynamically to temperature changes and other disturbances.

A. The importance of tuning:

The PID algorithm is a powerful framework. However, the performance of the PID system depends on how well its parameters are tuned: the proportional gain Kp, the integral gain Ki and the derivative gain Kd. The controller will respond to errors in a certain way based on these parameters. The temperature control system can perform poorly if it is not tuned correctly. This could be due to insufficient heating/cooling, slow response times or excessive overshoots beyond the setpoint. The system will respond quickly and accurately to the set temperature. It will also operate smoothly and steadily.

B. B. Common tuning methods:

Tuning the PID Controller is the process of determining the best values for Ki, Kp and Kd. There are several methods, from basic rules of thumb to sophisticated techniques.

Ziegler and Nichols tuning is a method that's often cited, which can be useful to get a good starting point. The method begins by identifying the critical gain (Kc), and critical time (Tcp), for a system. The critical gain (Kc) is the maximum gain that causes the response of the system to an input step to become unstable. It then begins to oscillate at a constant frequency. Critical time is defined as the duration of an oscillation when this critical gain has been reached. Ziegler and Nichols provide empirical formulas for estimating the PID parameter values once these experimental values have been determined:

To calculate the Kp value for a proportional only (P) control: Kp = 0.5*Kc

For a Proportional-Integral (PI) controller: Kp 0.45 * Kc, Ki 0.83 * Kc / Tcp

For a Proportional-Integral-Derivative (PID) controller: Kp 0.6 * Kc, Ki 2 * Kc / Tcp, Kd Kc * Tcp / 8

The initial values of the parameters can be adjusted manually or by using more sophisticated methods.

Manual tuning is another option. It involves carefully monitoring the response of the system to minor adjustments made in PID parameters. Typically, the process begins with tuning Kp to get a stable but fast response. After Kp has been set to a reasonable level, the Integral (Ki), is then tuned in order to remove the steady state error. The Derivative (Kd), which dampens oscillations, is then tuned. The trial-and error approach is a method that requires patience, and an understanding of system dynamics.

C. C.

It is not always possible to determine the exact values for Kp, Kd, or Ki that are required for the best performance. They are dependent upon the specific characteristics of the system. The tuning is influenced by the thermal mass (how much heat must be added or taken away) of the system, the heat transfer coefficients and the level of precision desired. System with high thermal masses tend to be slower and require smaller gains. Systems with rapid response time may tolerate larger gains. Tuning is often required if system conditions or configurations change.

VI. The PID control in temperature systems has many advantages

The PID controller is the best choice for temperature control tasks because it offers many advantages.

A. The PID controllers can achieve very high accuracy levels in the temperature control. The system is able to track and maintain the setpoint with minimum deviation by using the PID terms.

B. Stability: In particular, the derivative term plays an important role in improving the stability of the loop. This helps anticipate errors and take corrective actions in advance, reducing oscillations. The system will respond in the same way even if disturbances occur or if setpoints change.

C. Flexible: The PID algorithm can be used to solve a wide range of problems regarding temperature control, from simple heating systems in homes to industrial processes that require strict temperature control. The Kp, Ki and Kd parameters can be easily adjusted for optimal performance in different operating conditions.

- The Proportional-Integral-Derivative (PID) Controller: A Comprehensive Overview

- Understanding Solid State Relays (SSRs)