Labs & Industry: PID-controlled water bath design for precise temperature control.

Build guides, Arduino PID Tuning, component selection and industrial applications. Expert techniques will help you achieve +-0.1degC precision.

1. Introduction

In scientific labs, pharmaceutical production and industrial processing, precise temperature control is essential. Water baths are notorious for their overshoots, long stabilization times and inconsistencies, which compromise the validity of experiments and quality. Implementing a Proportional-Integral-Derivative (PID) controller resolves these issues by delivering exceptional accuracy (+-0.1degC), rapid response, and energy efficiency. The article discusses engineering principles, implementation and optimization for PID-controlled baths. It uses authoritative resources to guarantee reliability.

2. Basics of Water Bath Systems

The water bath offers a stable environment for a wide range of applications, from incubation of cell cultures to chemical synthesis. The conventional system consists of a heated tank, a sensor for temperature, an even heat distribution mechanism, and a insulated enclosure. In industrial variants such as the ones detailed in Cole-Parmer’s technical guide for crucial processes, corrosion-resistant materials are used and redundant safety devices. In sensitive applications, the limitations of thermostatic control (on/off), become apparent. Heater cycling can cause temperature variations exceeding +-2degC and require advanced regulation.

3.Principles of PID Control Theory

The PID controllers adjust the output dynamically based on 3 error correction components

Proportional (P): Reacts instantly to temperature variations (e.g. reducing the power when the setpoint is near).

Integral: Accounts for historic deviations to eliminate residual errors.

Derived (D) : Predicts future errors by using rate of change calculations. This reduces overshoot due to thermal inertia.

Control Engineering describes how this trio outperforms simple on/off controls by adapting to changes in ambient temperature and minimizing oscillations.

3.Critical Components and System Architecture

Hardware Select

Sensor: The platinum RTD sensors (PT100), offer +0.1degC more accuracy than thermocouples in the sub-100degC temperature range (Omega Engineering).

Heater Immersion heaters from 500W to 1500W matched with bath volume. (Calculate using: P = V * DT* 0.00116/t where V is in liters and DT is in degrees Celsius, while t hours are in hours.

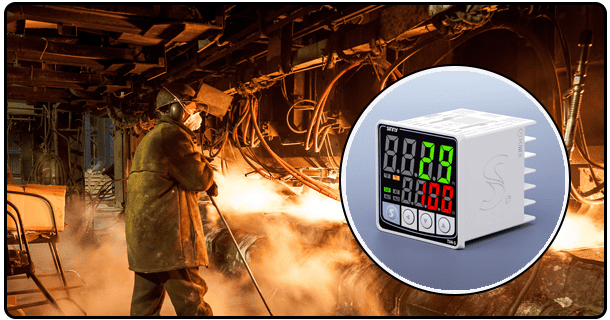

controller: Arduino/Raspberry Pi and PID libraries to prototype; industrial units such as Omega CN7500, for mission critical use.

Actuation Solid-state relays are a quieter alternative to mechanical relays for high-cycle switching.

4. Implementation Protocol

Mechanical Assembly Position the sensor close to the heater, but away from any direct contact. Use polyethylene foam to insulate the tank.

Circuit Integration Connect SSR via optoisolation to microcontroller. Fuse protection and thermal shutoffs can be integrated.

Calibration Validate sensor readings with a NIST traceable reference thermometer for multiple temperature zones.

Safety Systems : Set software limits and hardware trips (e.g. disable heaters if temperature exceeds setpoint by >5degC).

Methodology for PID Tuning

The optimal tuning is a balance between speed and stability.

Manual Method

Set Kd=0. Increase Kp to a point where oscillations are sustained (ultimate gain of Ku).

Target Kp = 0.6Ku, Ki = 1.2Ku/oscillation period, Kd = 0.075Kuxperiod.

Ziegler Nichols : Use step response data (Control Guru explains this).

Auto Tuning Commercial PIDs such as Siemens S7-1200 calculate parameters automatically via relay tests.

Use a serial monitor to log data and plot the results in Python or MATLAB.

5. Addressing Implementation Challenges

Thermal lag: Compensation using cascade loops or derivative control.

Noise Sensor: Use moving-average filters (e.g. filteredValue=0.8xfilteredValue+0.2xrawInput).

Disturbances : Integrate feedforward control to prevent predictable disruptions. Omega Engineering’s troubleshooting platform provides mitigation strategies.

6.Demonstrating the Efficacy of

Biomedical Laboratories: Maintaining a temperature of 37.0degC+0.1degC in ELISA tests, reducing the number of false negatives.

Food Process Multi-zone PID Baths provide uniform pasteurization and reduce energy consumption by 30 % compared to thermostatic controls.

Material Testing : dynamic temperature ramps (2degC/sec) with minimum deviations during transitions.

Water baths are transformed into precise instruments by PID controllers, which improve reproducibility and productivity in the industry. Cloud-based monitoring, adaptive AI tuning and cloud-based control are just a few of the innovations that have enhanced their capabilities. PID systems are the best thermal management solution, whether they're used with open-source platforms to prototype or commercial controllers that can be scaled up. The community encourages engineers and technicians to test tuning parameters, and to contribute their findings.

- The PID temperature controller guide: setup, tuning & troubleshooting

- Precision Temperature Control: West Control Solutions & PID Controllers as Science