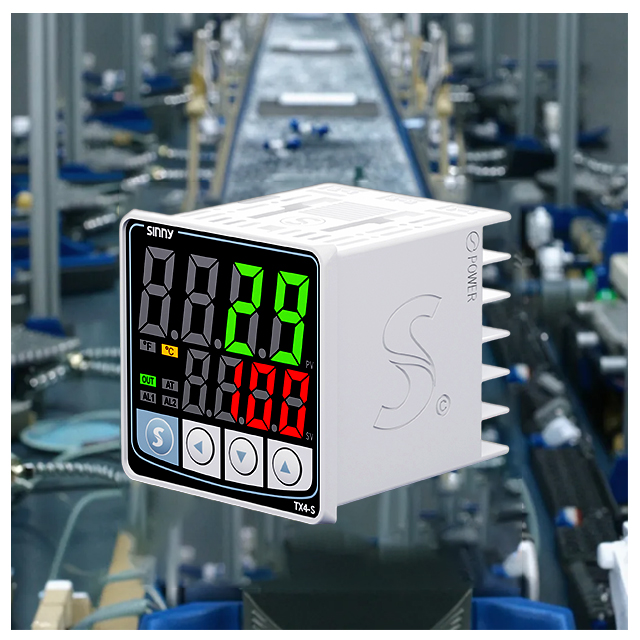

led pid digital temperature controller

1. Introduction

Proportional Action: The component that adjusts output according to the actual magnitude error. The output is adjusted based on the magnitude of an error. A small error will result in a much smaller adjustment. The proportional control reduces the error quickly, but leaves behind a residual (offset) error.

Integral action (I): The action takes into account the cumulative error over time. The output is continuously driven to remove the residual error from the proportional action. This component remembers past errors, and makes adjustments to the output in order to reach the set point, however slowly.

Derived Action (D), : The part that reacts on the change rate in the error. The Derivative Action applies an appropriate force to the system if the temperature changes rapidly. It helps stabilize the system and reduce overshoot, (when temperature exceeds the setpoint) as well as improve response times.

This combination of three tuning parameters (Kp, Kd, and Ki - these are the actions) will determine how well the controller performs in a particular application. Modern PID Controllers offer a sophisticated interface for monitoring and setting the parameters. This principle must be understood to ensure that the connection and tuning are successful. Resources such as Control Engineering’s Introduction to PID Control will help you further understand this principle.

2. Laying the Foundation for Your Connection

Planning is the key to a successful connection. This stage should not be rushed as it can result in incorrect wiring and configuration, damage to equipment, or safety concerns.

Define Your System Clarify the process or system whose temperature requires precise control. What is the normal temperature range? What accuracy is required? How much thermal mass is required and how long does it take for the system to respond? The controller and actuator specifications are determined by this information.

Choose the right controller: PID Controllers do not all have the same features. Take into consideration factors such as:

Control algorithm: Does this controller have a standard PID or advanced algorithms? (e.g. Smith predictor and filter options) Or does it offer anti-reset protection against windups.

Input types: Ensure that the controller is capable of accepting the sensor signals you intend to use.

Which output type will you choose? There are many options, including Solid-State Relays for fans or heaters, Relay outputs that control solenoids or contactors, Pulse Width modulation (PWM), outputs used to direct control fan speeds, and Analog Voltage/Current for interfacing other controllers.

Communications: Is the application requiring communication for monitoring, logging, or integration with a larger system (e.g. Modbus RTU/TCP/Profibus, Ethernet/IP, etc.)?

Interface and Display: Which level of interface do you need? What is better, a simple LCD or an advanced HMI?

Calibration is a consideration: Initial calibration may be required depending on the requirements of the application and the state at which the sensor/controller was initially installed. This will ensure that the readings are accurate and that the control system works correctly.

Bridging the measurement gap: Connecting the temperature sensor

Temperature sensors are the "nose" of the controller - they measure the temperature. Thermocouples, such as Type K, E, or J, and Resistance Temperature Sensors (RTDs, Pt100, Pt1000) are common industrial sensors.

Locate sensor input terminals: Locate the designated input Terminals on the PID Controller Panel, which are often marked "IN", THERM", "TC", and "RTD".

Determine Sensor Type: Be sure to identify the type of sensor that you're using. This type of sensor must be matched by the controller.

The Wiring Diagram is below: Consult the PID controller manual for its wiring diagram. The diagram will tell you how to connect the RTDs and thermocouples (e.g. three or four wires for RTDs and standard thermocouple) and what polarity is required.

Thermocouple Ex: Usually connected with specific connectors, e.g. BNC, DB9 or screw terminals. This diagram shows which wires connect to each terminal, and whether cold junction compensation has been built-into the controller or if an external sensor is required.

Example of RTD: Can require up to four wires, depending on whether the sensor element is used and how it's excited. Wiring diagrams will detail the proper connections for accurate resistance measurements.

If terminal blocks are available, use them. Avoid direct screw connections for greater reliability.

Calibration Test (Optional, but Recommended): Perform a basic test after wiring if you are able to access a temperature source that is known and have a thermometer calibrated. Verify the temperature displayed by the controller against the calibration. With the calibration capabilities of your controller, you may be able to make minor adjustments.

Executing Control Command: Connecting to the final control element (Actuator).

It is "the muscle" of the entire system. The PID receiver adjusts process temperature based on the signals received from the PID.

Identify Actuator Determine which device is going to adjust the temperature.

Locate the Output Terminals Look for the output terminals of the PID control, which are often marked "OUT", "AO", or "DA" (Digital/Relay-Output).

Select the output type to match with an actuator: Make sure the output of the controller matches the input requirement for the actuator.

Analog output (AO/DA). Digital/Relay output (DA): Used for switching power to devices such as contactors and relays, which then control large loads. Attention should be paid to voltage ratings (e.g. 5V logic or 24V relay coil), and the wiring configuration (normally open (NO) or normally closed (NC). It is important to set the controller output correctly (e.g. pulse length and duty cycle).

Wire an Actuator Connect your actuator in accordance with its datasheet. If you are using relay outputs to switch devices, make sure that the device is properly wired in between the NO/COM (or NC/COM depending on the application) terminals of the output and the source power. Connect the input wire of the analog actuator to the controller's signal.

Set output range/scale: Open the configuration menu of your controller (normally via buttons, an LCD screen or PC-interface software). Navigate to output and adjust the parameters to suit your actuator. Set the output range (for example, from 0-100% to 0-10V).

Connecting power to the controller: Energizing System

3. A stable supply of power is required for the PID to work. Wiring incorrectly can lead to serious danger.

Locate the Power Input Terminals. Look for the terminals "AC IN", VAC", or other similar terminals located on the back or side of the controller.

Switch off main power at source fuse/breaker.

Connect the terminals of the controller to the power source (Live, Neutral and Ground). The wiring diagram is in the user manual.

Connect the power supply, which is usually the fused cable from the AC main power.

Safety & Polarity: Check all connections. Before touching any wires, ensure that the electricity is turned off. Check the phase of AC power (L1/L2/N/G). The controller can be damaged by incorrect polarity when using DC power.

Tuning Algorithms for the PID controller

4. The controller's intelligent comes alive during configuration. Attention is required at this step.

Configuration Mode Access: Enter the programming mode using the keypad or buttons on your controller, or by using a PC-interface software. This can be indicated with specific LED patterns, or by a change in display mode.

Set Setpoint (SP). Use the keypad on the controller to enter the target temperature.

Set Input Type (Sensor Type): Choose the appropriate input type from the settings of the controller (e.g. TC Type Pt100, RTD Type K). The controller will then interpret the signal from the sensor correctly. Certain controllers offer cold junction compensation when an external sensor has been used.

Select Output Range/Type: Choose the output range/type of your controller (e.g. Voltage, Relay, PWM). Set the output range to exactly match your actuator requirements (e.g. 0-100%, 0-10V, 4-20mA). The correct control signal application depends on the scaling.

Setup of initial PID parameters (Tuning). This part is usually the most complicated. Initial parameters are often adjusted ("tuned"). Autotune or "Auto Tune", a feature of many controllers, performs an automatic test, which involves a change in the setpoint (often with a small step) to observe how it responds. It then calculates P, I and D values. Refer to manual PID tuning resources (such as the Ziegler Nichols method) if you prefer or need it. Adjust incrementally, starting with conservative values. Monitor the response of the process (minimal overshoot and quick settling) while adjusting. It is important to tune the control system in order to achieve a stable, responsive and oscillation-free operation. Honeywell application notes provide many practical tuning strategies.

Output filter and dampening: Certain controllers have an output-filter setting that smooths out noise signals coming from sensors, which prevents erratic actions. Some controllers have dampening functions that can reduce hunting or overshoot (small oscillations near the setpoint).

Bumpless Transmission: Configure bumpless transmission if the controller is capable. This allows you to change the parameters or setpoint without having the signal jump suddenly. It could cause overshoot, or even damage your system.

Save and exit: Once settings have been configured, make sure they are stored in the memory of the controller (check your manual to find out the exact save command). Exit the configuration mode.

Verification and Testing: Validating Performance

5. It is important to test thoroughly after physical configuration and connection in order to ensure correct performance and verify the operation.

Visual inspection: Check all wires for insulation, correctness and security.

Power up: Replace the fuse or breaker at the power source.

Initial Response Monitor: Look at the display of your controller. Is it showing the right temperature? Do the actuators respond? (e.g. does the heater switch engage or does the fan begin to run) Check the display for error messages.

Check Sensor Reading: Use an independent, calibrated temperature meter, or portable data loggers (such as devices made by Pico Technology, or National Instruments), to verify that the displayed temperature is the same. Check sensor calibration if necessary.

Close-Loop control: Modify the Setpoint (SP). Watch the response of the system. Is the system able to reach the setpoint accurately? Is it accurate? Are there any excessive oscillations or overshoots around the setpoints? Watch the approach rate and stability.

Final Tuning: If necessary, revisit PID parameters in light of the initial performance. For optimal performance, minor adjustments may be required. This is especially true for Integral Action to reduce steady-state errors and Derivative Action to increase stability.

Data Logging (Optional). If your controller has data logging capabilities, you can enable the data logger to log temperature data and output control data. It can prove invaluable in analyzing the performance of your system and for troubleshooting.

Common Problems and Troubleshooting: How to Solve them

6. Even with careful planning, problems can still arise. Here are some symptoms that may occur and their potential causes.

Temperature Not Changing / Controller Output Not Active:

Verify that the setpoint has been set properly and is within the range of the process.

Check that the output configuration is compatible with the actuator requirements.

Test for electrical power (lights on, motor running).

Verify the wiring from the output terminals of the controller to the actuator.

If the display on the controller does not show the desired value, check the output.

Hunting Oscillations:

Cause: Too aggressive PID parameter (too low Integral Time Ti or too high Derivative Time constant Td).

Solution: Reduce Kp or Ti. Consult the tuning section.

Look for any external problems (e.g. drafts that affect a smaller system).

If the system appears to be mechanically unstable, such as by loose components (e.g.), it should be checked.

The following are examples of slow response / large steady-state error (offset)

Cause Insufficient Integral Action (Ki) and/or overly conservative proportional gain (Kp). The filter settings could be set too aggressively.

Solution Decrease Integral Action (decrease Ti), or Increase Proportional Gain (increase Kp). Make sure the integral time corresponds to the response time of the system.

Incorrect Sensor Reading / Controller Display Drifts:

Cause : Poor wiring (loose or broken connections, interference), calibration drift of the sensor, cold junction compensation incorrect, sensor failure.

Resolution: Check sensor configuration. Verify sensor connections and wiring. Recalibrating either the controller or sensor's cold junction can be considered. Diagnose the problem with a calibrated thermometer.

The Actuator is not responding correctly:

Cause : Improper actuator wiring, actuator failure, incompatible output signals from controller, defective relay or SSR.

Solution: Consult datasheet of actuator. Verify that the wiring is in accordance with its specification. Check that the output of the controller matches the input requirement for the actuator. If possible, test the actuator on its own.

Consult the manual of the PID controller before you begin troubleshooting. Forums like Control.com and Instrumentation.com are also great resources to share experiences.

- The PID control for temperature: principles, implementation & tuning

- How to configure and connect a PID controller.