Mastering temperature stability: the definitive guide to PID control

1. PID Temperature Controllers

Precision is the key to success in industrial processes, scientific research and temperature regulation. Among control methodologies, the Proportional-Integral-Derivative (PID) algorithm emerges as the gold standard, deployed in over 99% of industrial thermal systems. Originating from Elmer Sperry's early 20th-century maritime stabilizers, PID evolved into microprocessor-driven precision, now governing reactions demanding +-0.1degC accuracy. PID is a dynamic power-adjusting thermostat that maintains equilibrium. It's a great alternative to primitive thermostats, which oscillate randomly. Control.com highlights that this feedback mechanism is "the spine of modern automation," turning volatile thermal processes in to predictable and repeatable operations.

2. The PID Algorithm: Breaking Down P, I, and D

Three interconnected math operations are used to calculate the PID's adjustment.

Proportional (P),: Reacts instantly to the current error. When a furnace's temperature is below the target by 10degC, P can apply 70 percent of its power. But P alone causes a "droop", i.e. persistent minor offsets.

Integral corrects past errors. I-action, for example, increases the power gradually to remove residual drift if, over 30 minutes, a reactor has lost 0.2degC/min.

Derived (D) : Predicts future errors by analysing the temperature change. Preemptive power is reduced when the temperature rises rapidly towards setpoint, cutting overshoots by up to 80%.

National Instruments clarifies that the output is as follows:

Power Adjustment = P(error) + I(error) + D(Derror/Dt)

The triad is a continuous self-correcting feedback loop that continuously refines the response to disruptions such as door openings and sample inserting.

3. Why PID Dominates Temperature Regulation: Key Advantages

Unmatched precision: Stabilizes at +-0.1degC compared to +-2-5degC for on/off systems. This is crucial when performing enzyme tests or growing crystals.

Energy Efficiency Reduces energy consumption by 25%-40% through minimizing heating cycle losses.

Disturbance Resist: Compensation for changes in load (e.g. adding cold samples into an incubator) is made within seconds.

Auto-tuning: Variants dynamically recalibrate to new environmental changes or setpoints.

4. Critical Applications Across Industries

Biotech : thermocyclers that require exact transitions between 55 and 95degC for DNA amplification.

Plastics Injection molding using barrel zones of +-1degC to prevent degradation.

Food Process Pasteurization Tanks Maintain 72degC plus or minus 0.5degC to ensure safety.

Aerospace : Multi-zone PID Controlled Composite Curing Ovens (Omega Engineering 2023).

Energy : Concentrated Solar Plants regulating Molten Salt Circuits at 565degC.

5. Tuning PID Controllers: Methods & Best Practices

Manual Tuning employs empirical methods:

Ziegler Nichols : Increase P-gain to induce oscillations. Set P=0.6xcritical gains, I=0.5xoscillation periods.

CohenCoon : Optimized to handle slow processes. Prioritizes faster settlement over aggressiveness.

Auto Tuning is the dominant system in modern systems.

The controllers measure the lag/response of self-configured parameters by injecting test pulses.

Software like MATLAB Simulink allows you to simulate the tuning of your system before it is deployed.

Pro tip: Start with P, add I for droop elimination, and then introduce D >0.1xI in order to dampen the overshoot (Control Global, 2021).

6. PID vs. Alternative Control Methods

Parameter PID control Control of On/Off Fuzzy Logic

Accuracy +-0.1degC +-2-5degC +-0.5degC

Fast Response One to thirty seconds Two to ten minutes 10-60 Sec

Energie Efficiency The High-quality Low-cost The Medium

Complexity Modest Low-cost The High-quality

Ideal Use Case Precision Manufacturing Home heaters Nonlinear processes

7. Implementation: Hardware & Software Solutions

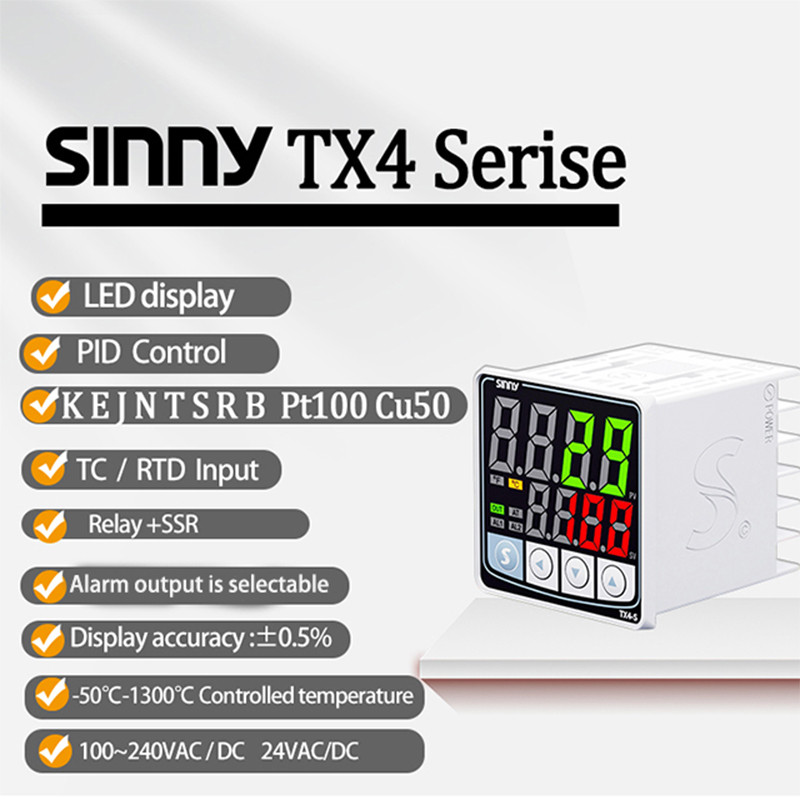

Stand-alone controllers: Eurotherm series 3500 (programmable ramps/soak profile).

Integration of PLCs Siemens SIMATIC S7 PID Function Blocks for SCADA Systems.

Open Source: Arduino PID library + MAX31855 temperature module (cost: about $50).

Industrial Software : Rockwell FactoryTalk real-time adaptive tunning.

8. Troubleshooting Common PID Issues

Overshoot/Cycling : - Reduce P-gain, increase D-action.

Stabilization : - Increase P-gain, reduce integral time.

Sensor drift: Annual calibration of RTDs per NIST SP250-98.

Electrical noise Install shielded cable with grounded conduits.

9. Future Innovations in PID Technology

AI Driven Tuning : neural networks that predict optimal PID values (IEEE 2022).

Wireless IIoT: Cloud-synced PID controllers enabling remote diagnostics via OPC UA.

Quantum QPI: Experiments using qubit feedback to nanosecond adjust the controller.

Sustainability Designs: Integrate with renewable microgrids and dynamic power throttle.

10. Conclusion & Practical Recommendations

For precision thermal management PID remains the only control that balances responsiveness and efficiency. Implementation:

Choose auto-tuning controls for dynamic processes, such as reactors.

Use IR imaging to validate sensor placement in thermal gradients.

Perform bi-annual calibrations traceable to NIST.

"Even as AI advances continue, PID’s mathematical beauty will ensure its dominance in decades to come."