PID Controlled Heaters: Science and Benefits

1. The following is a brief introduction to the topic:

Precision thermal control is a key element in reproducibility of science and quality assurance. Heating blocks integrated with Proportional-Integral-Derivative (PID) algorithms deliver unprecedented temperature stability, outperforming conventional thermostatic systems by orders of magnitude. The specialized instrument consists of metal thermally-conductive blocks with integrated sensors and heating elements. They are controlled by PID microprocessor controllers which dynamically change the power output. These instruments are used in pharmaceutical research, material testing and electronic manufacturing where fluctuations of +-1degC can affect reactions or products. The PID system achieves tolerances of +-0.1degC, which is a requirement that cannot be negated for applications such as PCR amplification and chemical synthesis.

2. What are PID heating blocks?

Four components are included in the operational framework.

Heaters: Ceramic or resistance wire assemblies that generate heat when electrified.

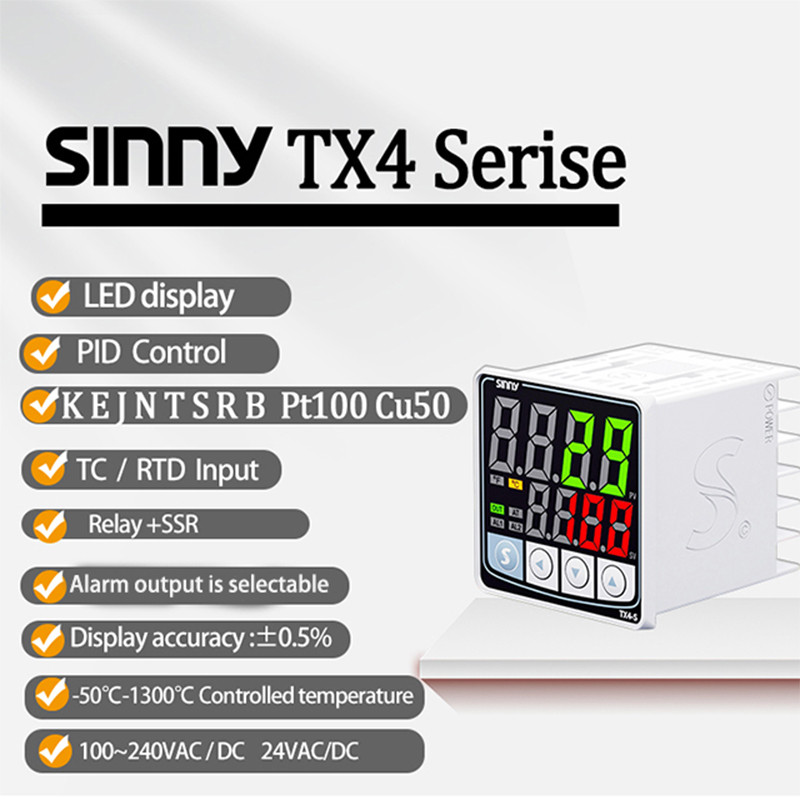

Sensors High accuracy RTDs or thermocouples are embedded into the block.

PID controller is a microprocessor that performs real-time errors correction through three computation actions.

Proportional (P): Adjusts the power in proportion to temperature error (e.g. +5 degC error equals +50% power).

Integral (I): Eliminates drift by correcting residual errors that have accumulated with time.

Derived (D) : Predicts future deviations by analyzing the rate of change, thus preventing overshoot.

User interface: digital displays and tactile/software control for setting point programming.

Omega Engineering’s technical guide explains that this "closed loop feedback system" creates an equilibrium in thermal ranges by using millisecond adjustments based on sensor data.

3. The benefits of PID-controlled heating blocks

Accuracy Maintains stability of +-0.1degC compared to +-5degC for bang-bang controls, which are critical in enzyme reactions.

Quick Stabilization Reduces soak times by up to 60% by reducing overshoot by using predictive D-control.

Energy Efficient: The dynamic power modulation reduces electricity use by up to 30% compared with relay-based system.

Equipment life-span extended: Reduces thermal cycling stresses on heating elements and samples.

Process reproducibility: Allows for identical thermal profiles to be achieved across several trials. This is noted by Cole-Parmer in their industrial analysis.

4. Top Apps

Molecular Biology Uniform heating of microcentrifuge tubes for PCR digestion, ligation and restriction digestions.

Analytical Chemistry Sample preparation via controlled vial digest for HPLC/GCMS.

Electronics Manufacturing : Thermal cycling and reflow soldering tests for PCB assemblies.

Materials Science : Testing of composites and polymers under isothermal conditions.

Food Safety Labs : Precision media tempering, incubation and Torrey Pines Scientific modular systems.

5. How to choose the right PID heating block: A Buyer’s Guide

Choose units that are aligned to operational needs:

6. Comparing DIY and Commercial Units

Home Improvements

Arduino-based kits, such as Instructables open-source designs (for example), offer customization at a low cost using MAX6675 temperature sensors and SSR relays. Uncalibrated sensors can lead to +-5degC errors, while inadequate insulation is a fire hazard.

Commercial Systems

Thermo Fisher, Grant Instruments, and other brands provide traceable calibrating, technical support and redundant safety system. The auto-tuning algorithms of these brands dynamically optimise P-I.D. values to suit varying loads. This is a feature that DIYers are rarely able to achieve.

7. Best Maintenance and Safety Practices

Calibration Validate sensors quarterly using NIST-certified reference standards.

Cleaning Remove any residues using isopropyl ethanol to avoid thermal inhomogeneity.

Safety protocols

For corrosive materials, use PTFE coated blocks.

Employ fume hoods during volatile reactions.

Magnetic thermal cutoffs can be integrated into the controller without a PID.

Troubleshooting : Uneven temperatures are often caused by loose contacts on sensor elements or degraded heaters. Lab Manager Magazine recommends maintaining maintenance records for audit compliance.

8. Future Trends

IoT integration: Remote monitoring in real-time via cloud platforms, e.g. Thermo Fisher Connect.

Machine learning: adaptive PID algorithms which self-optimize vessel geometry.

Sustainable design: phase-change materials compatible with renewable energies and thermal buffering.

Advanced Materials Graphene blocks with ramp rates of 200degC/sec.

9. The conclusion of the article is:

The convergence of thermodynamics and precision engineering is exemplified by PID-controlled blocks. They enable innovation in research and industry by overcoming the limitations of conventional heating methods. Commercial systems provide the necessary reliability for mission critical applications. DIY projects are a great way to get started, but they can be a good entry point. As thermal management evolves toward smarter, greener solutions, PID technology remains the bedrock of temperature-dependent processes.

- Mastering temperature stability: the definitive guide to PID control

- Understanding Dual Loop PID Temperature Controllers: Advanced Control for Complex Systems