Programmable PID Temperature Controller: Optimizing Precision Control

(Introduction)

Precision temperature control is essential in a wide range of industries. From manufacturing to laboratory research, HVAC systems and even food processing. This precision is often achieved by sophisticated feedback mechanisms called controllers. Among the most effective are Proportional-Integral-Derivative (PID) controllers, but not all are created equal. A PID temperature control that is programmable offers an important advantage. It allows you to customize its behavior to suit your application through tuning and configuration. In this article, we will explore what makes a PID temperature controller programmable. We'll also discuss how you can configure the device effectively and why flexibility is important for accurate and reliable temperature regulation. Engineers and technicians can achieve maximum performance by understanding these units.

What is the programmable PID temperature controller?

(Section : Definition and core benefits)

A PID temperature control , also known as a programmable temperature controller , is an electronic device that automatically maintains a process parameter (usually temperature) within a setpoint by altering its output signal according to the error between the measured Process Variable (Process variable PV) and setpoint. A PID controller is different from simple on/off controls that turn the system on or off. It uses three components to control its algorithm.

Proportional: Responds to current error. Output changes in proportion to error magnitude. Higher Proportional Gains (Kp), however, result in stronger corrections. However, too many can lead to instability.

Integer (I): Responds to the error accumulation over time. The purpose of this function is to remove any residual error in the steady state (the "offset") by integrating error signals. Integral Time (Ti), a parameter, determines the speed at which this error accumulates and influences output. Smaller Ti values mean faster correction of persistent errors.

Derived (D): Responds to rate of error change. This parameter predicts the future and dampens oscillations to improve stability. Derivative Time parameter (Td), controls the amount of 'future action' that is expected based on error rate.

User Interface (UI), and Configuration Capabilities are the key features that distinguish programmable controllers. Users typically can:

Set your target temperature.

You can adjust the parameters P, I and D.

Choose the control mode (P, PID, or PI) you want to use.

Limit SP: Set the upper or lower limit for the variable process.

Set alarm outputs and settings.

Adjust display units (e.g., Celsius/Fahrenheit).

Some units are capable of customizing setpoints or changing the schedule.

The controller can adapt the control strategy to match the dynamic of the process that it manages. This leads to better accuracy, stability and responsiveness than fixed parameter controllers.

The Key Features and Components of a PID Programmable Controller

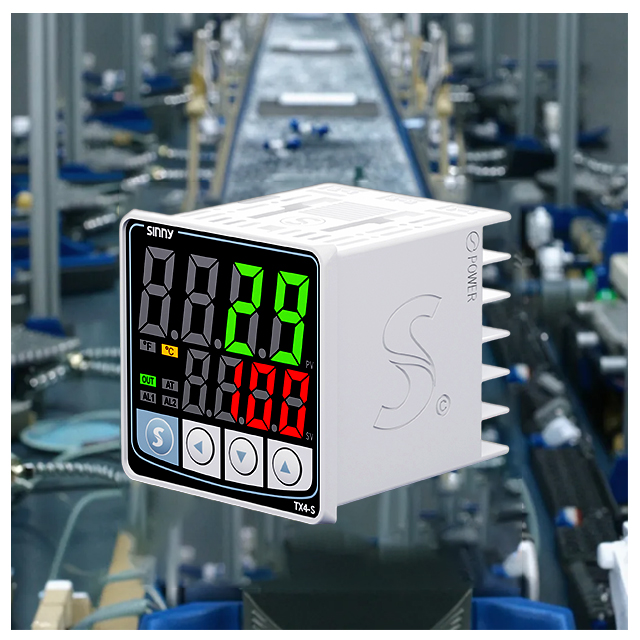

Interface Display: A LCD screen or LED display that displays the Setpoint, Process Variable and other parameters. Navigation and input are done with buttons or a rotating knob.

Input terminals: Connectors to:

Sensor input: Receives temperature signals such as thermocouples, Resistance Temperature Detectors, Pt100, or thermistors. Several inputs can be used with any sensor type, while others are specific for certain types.

Output terminals: typically includes:

Output Control: This is usually a solid state relay (SSR), or mechanical relay output. The output signal, which is often switched by a relay, controls the actuator at the end (heater or cooler).

Analog Output: Less common models have a voltage signal or alternating current that represents the percentage output.

Output Alarm: Separate relay contacts used to alert high/low temperatures.

Memory Internal: Retains the parameters programmed, as well as user presets and calibration data.

Parameters for Configuration: The parameters that users can adjust include:

Setpoint (SP),

Proportional Band or Gain

Time Integral (Ti).

Derivative Time (Td)

Lower/Upper Setpoint Limits

Lower/Upper Alarm Limits

The output mode (e.g. heating control, cooling control)

User Presets

(H2 Heading)

How to program and configure a programmable PID controller

(Section Configuration Process).

Entering the configuration mode of a PID controller and then adjusting parameters are required to program it. Consult the manual for your specific model and manufacturer to find out what steps you need to take. The general steps include:

To access Configuration Mode, you need to press specific buttons repeatedly (e.g. pressing the Menu button several times and then pressing 'Enter"). You can also hold a key during boot-up. Often, the display changes to 'Config" or other text.

Basic Configuration

Setpoint: Enter desired temperature.

Temperature Scale: Select degC or degF.

Type of Sensor: Select the right type of sensor (e.g. Type K thermocouple or Pt100 RTD), as it affects measurement accuracy and range. Some controllers auto-detect certain sensors.

PID Parameter Tuning:

Manual tuning: The user manually sets P, I and D values.

The Proportional Band is usually easier to set up than the Gain (Kp). A lower PB indicates a stronger proportional response. A good starting point for PB is 100/(required sensitivity).

Integral time (Ti). Enter your time in minutes or seconds. Ti values greater than 1 indicate a slower action integral. The typical values can range between seconds and hundreds of minutes depending on how fast the process is.

Calculate the derivative time (Td). Enter your time in seconds. This dampens oscillations. Begin with a small value (e.g. 0), and then increase it if necessary.

Resources like Control Engineering articles about tuning methods are helpful for manual tuning strategies.

Autotuning: Most modern controllers have an Autotune or "Autotune" function. This involves:

Start the Auto-Tune Mode.

The controller makes a slight change in the process, often by increasing output briefly.

This response is used to calculate optimal values for P, I and D.

Refer to the manufacturer's documentation for detailed instructions on how to use auto-tune.

Limiting and alarming:

The process variable must not be allowed to exceed the maximum or minimum temperature. The controller can then shut down the actuator, e.g. turn off the heater or activate the alarm output.

Set the output alarm action.

Output configuration:

Define your output range, for example, from 0% to 100%.

Use 'Bumpless tuning' features, if they are available. These allow you to change the parameters or setpoint without changing the output signal abruptly (preventing instability or overshoot).

Advanced User Presets: Store different PID parameters sets for different recipes and operating modes to allow quick switching.

Industrial Heating: Ovens (ceramic, paint baking, food processing), kilns, furnaces, heat treatment equipment.

Lab Equipment: Incubators and water baths. PCR machines. Dryers. Reaction vessels.

HVAC Systems Advanced climate control systems, thermostats requiring precision setpoints.

Food and Drink: Fermenters, chillers (chilling), proofing cabinets, cookers, pasteurizers.

Medical/Scientific: Equipment that requires stable temperature (e.g. centrifuges and incubators).

DIY Projects: Precision hobby controllers for small ovens, resin curing, etc.

The Right PID Programmable Temperature Controller

(Section : Criteria for Selection)

When selecting the right programmable PID control, you need to consider several things:

Match your specifications with the requirements of your application.

Compatibility with Sensors: Can it be used to support your chosen sensor (thermocouple or RTD? Thermistor or an external transmitter?) Verify that the input types match (e.g. mV or ohms for voltage and mA, respectively).

Control Loop Dynamics : Take into account the speed of the processes. In general, fast processes require less integral and derivative actions. Tuning range of the controller should be appropriate.

User interface (UI) : Does the display look clear and legible? The buttons are easy to operate. What features are available (e.g. multiple alarms? Trend display? Data logging?)

Price: The price of programmable PID controls varies widely depending on their features and quality. Decide on your budget, and then look at the value.

Support and Brand: Look for manufacturers who are known to provide quality products and clear documentation. Verify warranty options and customer service.

Referral: Sites such as InstrumentationTools compare and contrast different controller types, and also discuss the selection criteria.

(H2 Heading)

Use Programmable PID controllers with Care

(Section : maximizing performance and reliability)

Calibration To maintain accuracy, calibrate the temperature sensor and controller according to manufacturer's instructions or industry standards.

Considerations for Environmental Conditions: Make sure the controller suits the environment in which it will be used (temperatures, humidity, dust and electrical noise).

Safety: Follow safety precautions when handling electrical systems or hot processes. Utilise alarm functions appropriately.

(Conclusion)

Programmable PID temperature controllers represent a significant advancement over simpler control devices. The ability of these controllers to be tuned and configured offers unmatched flexibility for stable temperature control in a variety of applications. Understanding the PID components, the configuration process and the best practices will allow users to harness its power and improve efficiency, quality and reliability of processes.

- Programmable PID Temperature Contr oller

- PID Temperature Control Algorithm Industrial Implementation and Optimization Guide