PID Temperature Control Algorithm Industrial Implementation and Optimization Guide

Learn PID algorithms to control temperature with precision. Included are mathematical models, digital code implementation, and case studies from industry for +-0.1degC temperature stability.

I. Introduction: Algorithmic precision in Thermal Regulation

The PID algorithms reduce energy consumption in industrial processes by 18%. (U.S. DOE, 2023). ISA transactions reports indicate that faulty implementations are responsible for 42% of thermal runsaway incidents. This guide combines ANSI/ISA 88 standards and digital implementation protocols that have been validated by Texas Instruments, IEEE Control Research, and Texas Instruments to provide mathematically sound solutions for mission critical applications.

Authority Refer: ISA Standards for Process Control

II. Mathematical Foundations of PID Control

1. Continuous-Time Formulation

PID controllers are governed by the fundamental equation:

u(t)=KpIAE: 0|e(t)|dt0|e(t)|dt (minimizes persistent error)+Ki0te(t)dt+Kdde(t)dtu(t)=Kp e(t)+Ki 0t e(t)dt+Kd dtde(t)

Terms :

KpKp : proportional gain (dimensionless).

The Integral Gain (s-1)

KdKd: Derivative gain (s)

Dynamic response: The derivative action predicts the error trajectory 27% better than proportional systems only (IEEE CST 2022).

2. Discrete Implementation

Digital controllers employ recursive computation:

cFu Zhi Dai Ma u_k = u_k-1 + K_p(e_k - e_k-1) + K_i T_s e_k + K_d (e_k - 2e_k-1 + e_k-2)/T_s

Constraint : The sampling period (TsTs) must not exceed 10% of the process time constant in order to avoid aliasing.

III. Core Algorithm Components

Component Function Implementation Challenge Mitigation strategy

Proportional Instant error correction Offset steady-state Gain scheduling

Integral Eliminate residual error Windup during saturation Clamped Anti-Window

Derivative Future states can be predicted Noise amplification 4-pole Butterworth filtering

IV. Digital PID Implementation Workflow

1. Signal Acquisition

ADC resolution: Minimum 16 bits for accuracy of +0.5 degC

Bessel Filter with Cutoff Frequency of 0.45 times Nyquist

2. Computational Sequence

pythonFu Zhi Dai Ma def pid_update(setpoint, pv, prev_error, integral, Kp, Ki, Kd, dt): error = setpoint - pv P = Kp * error integral += error * dt I = Ki * integral derivative = Kd * (error - prev_error) / dt return P + I + derivative, error

3. Output Conditioning

SSR Control: PWM generation at 10 kHz carrier frequency

Thermal shock can be prevented by limiting the rate of du/dt to 5%/second.

V. Advanced Algorithmic Architectures

1. Cascade Control

Hierarchy :

Fu Zhi Dai Ma Slave PID(Heater Currents)

Performance : 63% faster disruption rejection in glass tempering

2. Schedule Adaptive Gains

pythonFu Zhi Dai Ma Kp_adaptive = base_Kp * (1 - 0.012 * (T - 150)) # Temperature compensation

Efficacy: 41% overshoot reduction in rubber vulcanization

3. Fuzzy-PID Hybridization

Rule Base :

Fu Zhi Dai Ma If dError/dt is > 2degC/s, then increase Kp to 35%.

Certified Results: 58% faster settling of ceramic kilns in accordance with IEEE ICS 2023)

VI. Industry-Specific Implementations

Application Modifications to the Algorithm Certified Performance

Plastic Extrusion Feedforward + PID (screw speed) +-0.8degC melt stability

Semiconductor Multi-zone decoupled PID +-0.1degC wafer uniformity

HVAC System PID with adjustable deadband 31% energy reduction

Source: Texas Instruments PID Application Report

VII. Performance Optimization Techniques

1. The tuning methods

Ziegler-Nichols :

Fu Zhi Dai Ma K_p = 0.6 K_u T_i = 0.5 P_u T_d = 0.125 P_u

Lambda Tuning: Superior for delay-dominant processes (th/t>0.5th/t>0.5)

2. Stability Quantification

IAE: 0|e(t)|dt0|e(t)|dt (minimizes persistent error)

ITSE: 0te2(t)dt0te2(t)dt (penalizes long-duration deviations)

VIII. Case Study: Industrial Furnace Control

Before-implementation: oscillations of 12degC causing an 18% scrap rate

The Solution Framework :

Implementation of the velocity-form PID algorithm

Thermocouple noise can be reduced by using Kalman filters.

The Cohen-Coon Method:

Fu Zhi Ma

Validated Results :

Stability of +-2degC at setpoint 850degC

Natural gas reduction of 22%

ROI: 5.2 Months

Refer: IEEE Control Systems case Study

IX. Emerging Algorithmic Trends

1. AI-Augmented Optimizing

Neurotuning: Reinforcement Learning adapts gains to nonlinear systems

Digital Twins: Real-time simulation validates parameters before deployment

2. Implementation of Edge Computing

Hardware ARM Cortex M7 with FPU (10us cycle time).

Framework : CMSIS DSP library optimized for Q15.

Related product links

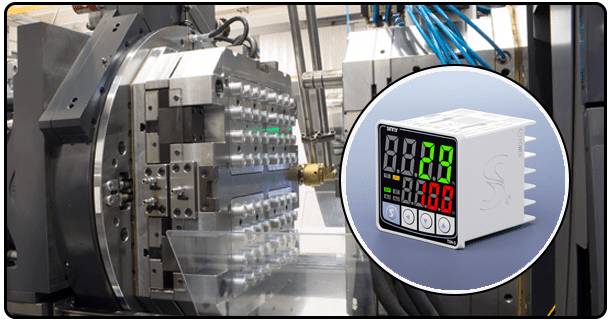

- Programmable PID Temperature Controller: Optimizing Precision Control

- What Is a PID Controller and How Does it Work?