220v pid Temperature Controller "Precise Temperature Control" in One Step - Comprehensive Guide

220v PID Temperature Controller is usually a type of temperature controller for household voltage. It can be used under any 220v voltage, which can help users achieve precise temperature control to improve comfort and save energy. The following is a comprehensive guide to the 220v PID Temperature Controller:

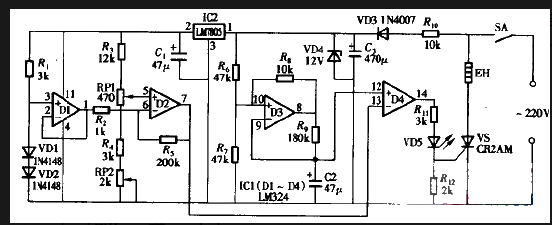

Working principle: As a commonly used 220v PID Temperature Controller, it is mainly composed of sensors, control circuits and actuating components. The sensor mainly senses the temperature signal through the needle part, converts the temperature signal into an electrical signal and transmits it to the temperature controller. Then, the control circuit compares the electrical signal brought by the sensor (the actual value sensed by the sensor is compared with the set value), and the working state is adjusted by the actuator based on the difference in the comparison.

sensed temperature ------ transmits the signal ------- and performs regulation by comparing the difference

1.First, understand why the ordinary thermostats on the market are "ordinary"

Ordinary temperature controllers are usually conventional ON/OFF temperature controllers ---- either stop or start. The machine stops when the temperature reaches the set target value and starts when it drops below. Its flexibility is very low, and it often suffers from temperature fluctuations, overclocking, and repeated jumping. It simply cannot meet the requirements of precision equipment.

The temperature controller based on the PID algorithm adopts a triple algorithm of proportional, integral and differential, dynamically adjusting the proportional value. While adjusting the parameters, it gradually eliminates static errors and automatically coordinates uniformly after judging the temperature change trend, ultimately achieving an accuracy control of ±0.1 to ±0.5℃. After stabilizing at this level, there is no fluctuation, which is something that ordinary temperature controllers cannot achieve.

2.220v voltage is suitable for both commercial and household scenarios

1.It can be directly matched with voltages for household use, laboratories, small workshops, and small equipment, etc., and has high versatility.

For large-scale industrial scenarios, the voltage is generally 380v

2. How to choose? These dimensions will help you understand

1. Check the "Temperature control range

The temperature you need to maintain in your usage scenario should be reasonably selected based on your requirements. When choosing a thermostat, it is recommended to select one with a mid-range temperature control range based on the actual required temperature. For example, if the temperature control needs to reach 50 degrees Celsius, it is suggested to choose one with a temperature control range of 0 to 150 degrees Celsius. It is necessary to avoid an "ultra-wide range" (if the temperature range is too high, the accuracy will actually decrease).

2. Check the output power

For a regular 220v voltage, a thermostat with an appropriate power must be selected. It is essential to ensure that it can drive your equipment. The size of the output power directly affects the power of the equipment it can drive (the power of the heating equipment ≤ the output power of the thermostat).

3. See if the function is suitable for you ----- make a reasonable choice

Upper and lower limit alarm function, PID self-tuning function that even beginners can adjust.

If there is a need for convenience: digital display large screen + touch screen/button, communication interface (RS485).

3. How to install and use? You can handle it yourself in two steps

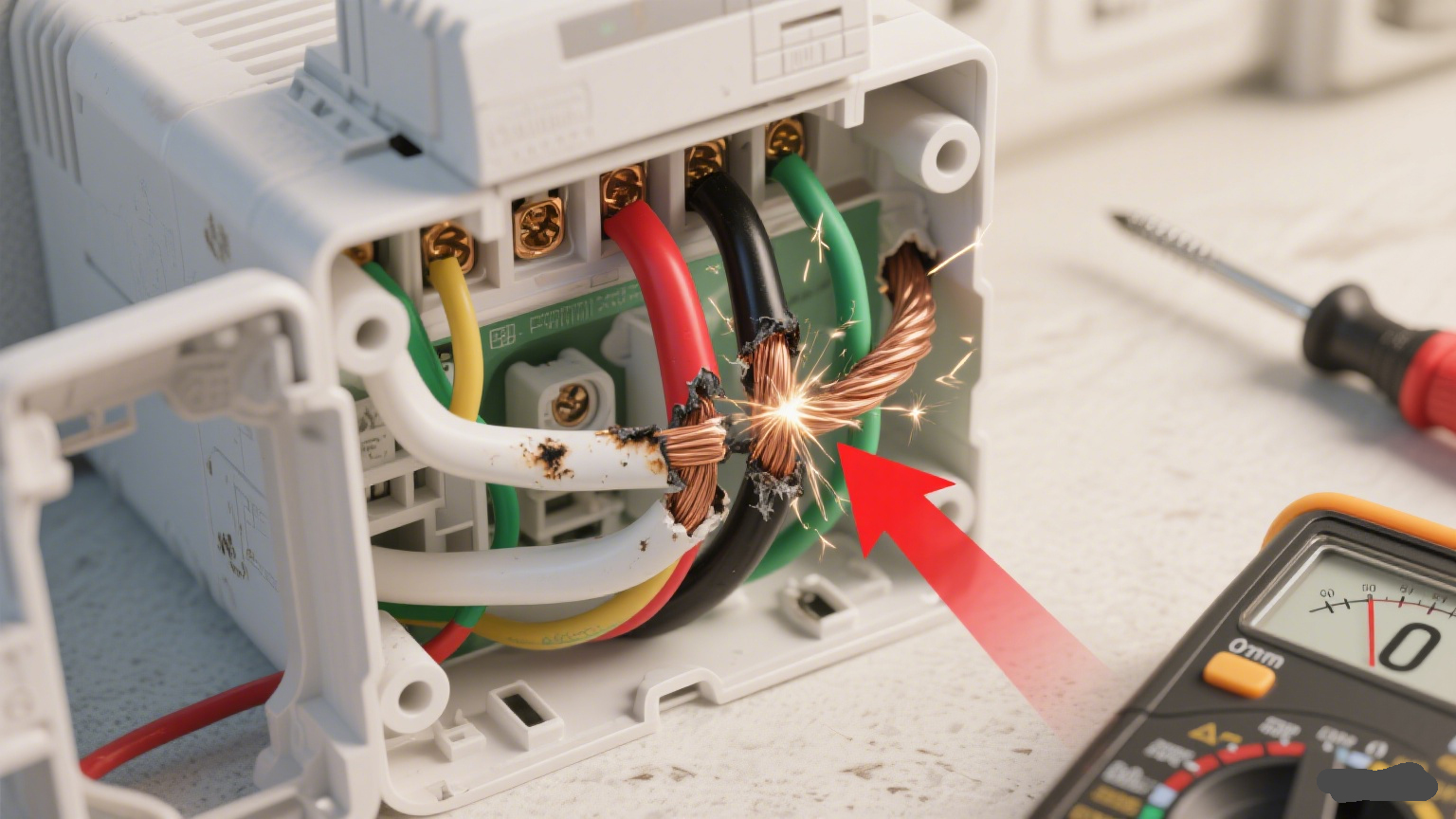

Wiring: Power input (L.N terminal) : Generally 220v voltage, connect L to the live wire and N to the neutral wire. Do not connect them in reverse; otherwise, it will cause a short circuit and burn out the equipment

2. Sensor input: Generally, a manual is provided when purchasing. Connect the positive and negative terminals according to the manual. Do not connect them in reverse; otherwise, temperature measurement will not be possible.

3. Output control: Generally, there is an OUT terminal on a thermostat, which is connected to the heating equipment. This set of wires is used to control the on and off of the equipment

4. How to Operate Precise "Temperature Control

1. Measure the temperature before turning on the machine: After connecting the power supply, observe the current temperature on the temperature control instrument and check if the sensor is functioning properly.

2. Set temperature: Generally, temperature control devices have +/- keys to control the values of PV and SV.

3. Self-tuning: The self-tuning function automatically adjusts the gap between the actual value and the target value for you, gradually approaching the target value. If manual adjustment is needed, the value of P I D can be modified.

What functions are needed in which scenarios? These items can be used as references

1. Laboratory culture dishes: Pursue high precision

2. Small processing plants: Pursue stable temperature to enhance the product qualification rate.

3. Commercial equipment: Fermentation requires low temperatures to ensure the survival rate of fungi (an appropriate temperature range is needed)

4. Medical equipment: It has relatively strict requirements for precision and stability

FAQ:

Does the thermostat consume a lot of electricity?

The power consumption of a regular temperature controller is higher than that of a pid temperature controller (due to its frequent start-ups and timeouts).

2. Will the accuracy decline after long-term use?

No. If it drops, it is most likely due to reasons such as corrosion of the needle of the sensor's temperature controller or the formation of an oxide layer

Regular cleaning/replacement is required.

3. Will the temperature get out of control due to a thermostat malfunction?

No, most PID temperature controllers have upper and lower limit alarms, overheat protection (dual slave protection) -----sinny temperature controller.

- How to Choose an Incubator Controller - A Comprehensive Guide

- Temperature difference controller - A Comprehensive Guide