A Guide to the TA4 Temperature Controller with SNR and PID: A Comprehensive Guide

1. Introduction

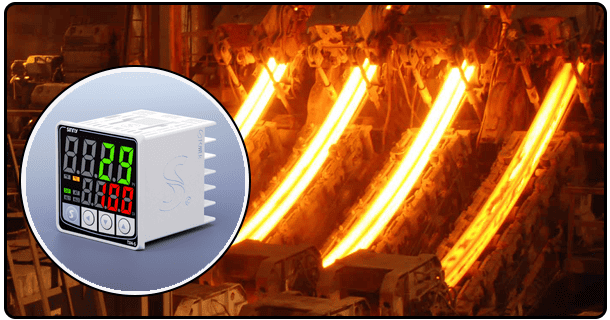

The TA4 SNR/PID Temperature Controller, a versatile and highly reliable device for temperature regulation precision in commercial and industrial applications. The TA4 SNR PID Temperature Controller is a highly reliable and versatile device designed for precise temperature regulation in industrial and commercial applications. The TA4 PID controller, by leveraging the PID mechanism that balances integral, proportional and derivative feedback ensures optimal performance, even under fluctuating conditions. This article provides a thorough overview of its working principles, features, applications and benefits.

2. Features and Benefits of the TA4 PID SNR Temperature Control

The TA4 SNR PID temperature controller is renowned as a versatile device with many features.

3. The TA4 SNR-PID Controller

To fully appreciate the TA4 PID SNR Temperature Control, it is important to understand its working principles. This controller uses the PID mechanism to control temperature:

Proportional Control This component adjusts the output of the control proportionally based on the error.

Integral control : This term addresses accumulated errors and eliminates offset over time.

Derivative control: This term predicts future errors by analyzing the rate of changes. It allows the system act pro-actively.

The TA4 SNR PID Controller can be integrated with temperature sensors for real-time feedback. The controller continuously measures the difference between actual and desired temperature, and adjusts heating or cooling systems as necessary. The dynamic feedback loop provides precise temperature control.

4. Application of the TA4 PID Controller

Its versatility allows it to be used in multiple industries.

The controller can be used to manage temperature in a variety of critical applications.

5. Setup of the TA4 PID controller

It is important to set up the controller correctly in order to get the most out of it. Here are the necessary steps:

Installation Install the controller and attach it to temperature sensors and actuators.

Calibration : calibrate the sensors connected to ensure accurate temperatures readings.

Configuration : Set the desired alarm threshold and program it.

Tuning : Use Ziegler-Nichols methods to adjust the PID parameters and optimize system performance.

Test Validate system functionality by testing under different conditions.

Follow these steps to ensure smooth and efficient temperature control.

6. Benefits of using the TA4 PID controller

The TA4 SNR PID Controller has several features that make it appealing:

Energy Efficient By minimising temperature fluctuations, a controller can reduce energy consumption and save money.

Cost Effectiveness The controller is a good investment because of its durability and ease of maintenance.

The TA4 SNR-PID Controller has many advantages that make it a popular choice for industrial and commercial uses.

7. Troubleshooting

Regular maintenance of your TA4 PID controller is vital to its longevity. Here are some solutions to common problems:

Sensor drift: Recalibrate sensors regularly to maintain accuracy.

Delay in Response: Replace worn actuators and check for issues with connectivity.

Update Your Software To Benefit from Bug fixes and improvements, update your firmware regularly.

Regular maintenance and prompt troubleshooting will preserve the controller’s effectiveness.

8. Comparative Analysis with Other PID Controls

The TA4 SNR is a superior PID controller on the market.

Enhanced stability: Compared with generic models, TA4 SNR provides better control stabilization, ensuring minimum temperature deviations.

Easy to Use: The intuitive user interface makes it easier for users than some of the complex competitors.

Compatibility with Sensors The range of sensors supported is unmatched in the industry.

The TA4 SNR has a distinct advantage over the other controllers.

9. Future trends in PID temperature controllers

Temperature management continues to be advanced by the evolution of PID controls. The following are key trends:

IoT integration: controllers with IoT capability allow remote monitoring, adjustments and control via cloud platforms.

AI Driven Control : AI powered adaptive algorithms optimize performance.

Improved sensor technology: Increased sensor precision increases the accuracy of feedback circuits.

These innovations show the relevance of PID temperature control systems and their advancement.

Its performance is optimized with proper maintenance and setup.

- Design of a Temperature Control System using PID Controller

- The Complete Guide to Temperature and Humidity Controllers: Applications & Comprehensive Guide