Article: Arduino PWM PID Temperature Control

I. I. Introduction

A. A brief overview of the temperature control requirements for DIY projects and smaller-scale

B. Arduino is a popular platform used for electronic hobbyists.

C. C. Introduction to Pulse-Width Modulation: A Control Technique

Pulse Width Modulation is an important technique for controlling the amount of power that an electronic device receives, especially an actuator such as a heater or motor. PWM is the rapid switching of a digital output between low and high states. The Duty Cycle is the most important parameter. It is the percentage of time that the output signal is high in a cycle. PWM simulates an analog signal by varying the duty cycle. In heating applications, higher duty cycles mean that the heating element will be on for more of the time. This increases the power, and therefore the temperature. A lower duty cycle will reduce the power and therefore the temperature. The method allows fine-tuning of the power.

D. Introduction to PID Control: Proportional-Integral-Derivative algorithm

Simple on/off controls may be sufficient for certain basic applications but they often fail to deliver the accuracy required for responsive and stable temperature regulation. The PID algorithm is essential in this situation. The PID strategy is a closed loop feedback control that uses the error as the difference in the target temperature and the actual temperature. This algorithm applies three different terms to the correction:

1.Proportional: This correction is proportional with the error. The correction is larger when the error is larger. This helps to get the system to its setpoint more quickly.

2.Integral: The corrective is proportional the error accumulated over time. The term is used to eliminate the steady-state errors - that is, the temperature drift when the system approaches the set point but does not reach it exactly.

3.Derived (D): Correction is proportional with the change in error rate. The term is used to predict future errors, using the current trend. It also helps to dampen the system and prevent overshoots and oscillations.

Combining these three terms can result in a better balance of responsiveness, accuracy and stability compared with simpler methods.

E. The purpose of this article is to explain how PID temperature controls can be implemented using Arduino and PWM.

This article's primary goal is to give a practical and detailed guide to implementing a PID Temperature Control System using an Arduino Microcontroller with Pulse Width Modulation for the Heating Element. The article will cover the fundamental concepts and outline all the components. It will also provide insight into how to program the Arduino so that it can execute the PID algorithms. We'll guide you through the hardware connection and give advice about tuning and testing your final setup. After reading this article, the reader should be able to construct their own Arduino PID Temperature Controller.

F. SEO Focus: Keywords like "Arduino temperature control," "PID temperature control Arduino," "PWM heating control," "DIY temperature controller. "

II. The Core Components

A. The Arduino Microcontroller - Role and basic operations (processing of inputs, control outputs).

The Arduino microcontroller is at the core of the Arduino temperature control system. Microcontrollers are a tiny computer that is built on an integrated circuit. The microcontroller contains an integrated processor, programmable I/O peripherals and memory for storing program code. In this case, the Arduino's primary function is that of the system control unit. The Arduino's main tasks are to read the temperature reading from the sensor and process it using the PID algorithm in order to determine the correct heating level. It then generates the PWM signal as well as controlling SSRs (Solid State Relays) or any other switching mechanisms to control the amount of power delivered to the heating element. It executes all the instructions programmed, making decisions in real time to maintain the temperature.

B. The selection of temperature sensors: common types (e.g. DS18B20 and DHT11/22 thermocouples with MAX6675, DHT11/22)

Temperature sensors are crucial to the accuracy and reliability. Different types of temperature sensors are used in Arduino projects.

·Sensors Digital: This sensor converts the temperature measurement to a digital code, making it easier for Arduino to interpret. The DS18B20 is a digital thermometer with a single wire that's known for accuracy, multiple sensors, and its multi-sensor capability. Other examples include the DHT11 and DHT22 which can measure temperature as well as humidity. The DS18B20 provides readings that are accurate to +-0.5degC with a resolution as low as 0.1degC. DHT temperature sensors have an accuracy of +-2degC. For accurate readings, digital sensors require library support from the Arduino.

·Analog sensors: This sensor produces an analog voltage output that is proportional to temperature. The LM35 linear sensor is a common example, as it outputs 10mV for every degree Celsius. Analog sensors are simple but can have noise. They require an analog-to digital conversion to read them (using Arduino's ADC).

·Thermocouples They are rugged sensors that can be used in a range of temperatures (from very low to cryogenic), but they have a lower level accuracy than digital sensor. The Seebeck effect is used to generate a slight voltage at the junction between two metals. Thermocouple voltages are often read using more complex circuitry, or ICs such as the MAX6675 which offers digital output and cold junction compensation for N-type thermocouples.

The selection of sensor is based on your application's requirements. This includes the temperature range required, the accuracy needed, the cost and I/O ports available on the Arduino board. The DS18B20 and DHT sensors are a great choice for most hobbyists projects. They offer a balance between accuracy, cost, and ease of use.

C. Considerations and types of heating element (e.g. resistive wires, resistance blocks, etc.)

Heating elements are the components that generate the heat needed to increase or maintain a process' temperature. There are several types available.

·Resistive wire (Heating coil): This resistive wire, which is often made of materials such as Nichrome or other similar metals, heats when an electrical current flows through it. The wire can be formed into coils or strips and then mounted into an object to heat.

·Blocks of Heating: Solid blocks are made from a thermoconductive material and embedded with resistive components. These blocks provide a uniform surface for heating and are used commonly in 3D printer hotends, laboratory incubators, etc.

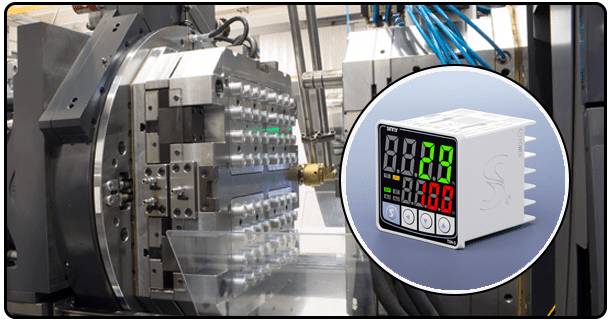

·Solid State Relays: Solid State Relays are switching devices. However, in this case they play a crucial role as an interface between the Arduino's low-power signal and the heating element. SSRs use semiconductor technology to turn on/off the main power supply. They are typically controlled via a low voltage input signal, such as the Arduino PWM output. The SSRs are faster and more reliable than mechanical relays (no metal contacts), but they also have a shorter lifespan.

In selecting the right heating element for your application, you should consider factors like power requirements, required temperature ranges, uniformity of heat distribution, cost, safety and more. The choice of switching mechanisms (SSR and relay) is also influenced by the type of power source (AC orDC).

D. Duty cycle concept and generation of PWM signal on Arduino

PWM, as mentioned previously, is a method of simulating analog signals using digital signals. PWM is supported by several pins on most standard Arduino boards. On boards with an 8-bit clock (like the Uno and Nano), these pins are capable of generating a square wave, which has a variable duty rate. The range is typically from 0% (always off) to 255 (always on). duty cycles represent the percentage in a cycle that the signal is active. A 0% duty-cycle means that the output will always be low. 50% duty-cycle means it will always be high, but only for half of the time. 100% duty-cycle means always high. The Arduino PID algorithm, when used for temperature control calculates a duty cycle (between 0 to 255) that is appropriate based on error. This value is then sent to the PWM connector connected to SSR. The SSR interprets this PWM signal to control the power average delivered to the heater element.

E. The PID algorithm: A brief recap of the terms (P, I and D) as well as its importance for dynamic control

Understanding the PID algorithm requires a recapitulation. It is important to understand the PID algorithm in order to implement it.

1.Proportional Term (P): This term produces a control out put proportional to current error. The P_output is equal to Kp*E. An increased error will result in a higher output signal that attempts to quickly correct the temperature. A high P gain, however, can make the system oscillate and overshoot its set point. The proportional gain constant Kp, which is a variable parameter, can be adjusted.

2.Integral Term (I): Iterm addresses cumulative error in time. The I term integrates error (E dt), and adds this to the integral value. I_output = KI * E dt. This term eliminates steady-state errors - temperature differences that remain even if the system is near the setpoint. The integral term will grow if the error is persistent for a prolonged period of time. This pushes the output to correct the problem. A too-strong integral can cause oscillations. The integral gain constant Ki can also be tunable.

3.Derived (D) Terms: D terms predict future errors by analyzing the rate at which the error changes. D_output = dE/dt * Kd. The system calculates error changes over time, and dampens its response by using this information. Positive D terms indicate that the system may be correcting the problem too rapidly and could overshoot. Therefore, it will reduce the output. Negative D terms indicate that the system has corrected too slowly. This results in an increase of output. D-terms help stabilize the system and prevent overshoot. The derivative gain constant Kd, is another parameter that can be adjusted.

This is how you calculate the PID output: U = Kp E + KiE + Kd*dE/dt. The calculated output is what represents the control action that you want to take, in this instance the duty cycle of the PWM. The PID method is especially effective in temperature control, as it simultaneously addresses the current error (P), accumulated error I and rate of change D. This results in a more accurate and stable response than other control methods.

F. SEO Focus: Keywords like "Arduino temperature sensor," "heating element arduino," "PWM control," "PID algorithm explained," "Arduino SSR. "

III. The PID Algorithm for Arduino

A. Set up your Arduino environment: IDE and libraries

This is because the core logic for the PID controller lies in the Arduino software. The Arduino Integrated Development Environment, a cross-platform free application created by the Arduino Team, is used to write the code (sketch). It includes a text editor and a debugging serial monitor. The program must interact with hardware, reading the pin from the sensor, calculating PID, and then writing the calculated duty cycle of the PWM to the correct PWM pin. The PID calculation can be complicated, but the Arduino community has a number of libraries to simplify the implementation. The PID_v1 is a popular choice. It provides an integrated framework for PID controls, and handles the derivatives calculations. The Arduino Library Manager is usually required to install these libraries. There may be other libraries required for certain sensor readings.

B. Read Sensor Data Code: This code allows you to read the temperature from the sensor.

First, you need to get the temperature reading from the sensor. The first step is to configure the digital pins or analog inputs on the Arduino. Next, you will need to use the right function or library in order for the temperature values. The OneWire is used, for instance, to send data over a 1-Wire network, while the read function of the DS18B20 sensor is invoked. For analog sensors like the LM35 the analogRead() Arduino function is used to read the voltage of an analog pin. This voltage can then be converted into temperature by using the sensor characteristics. The DHT Library handles the DHT sensor's specific communication protocol. To ensure that valid readings can be obtained, the code should include an error-checking function. The raw temperature value is passed on to the PID Library.

C. Write or use existing library code for the PID function on Arduino

Calculating PID is usually done within a library function. For example, the PID_v1library requires defining the structure of the PID, setting input, output and setpoint and calling the Compute()function in the Loop()function. The temperature reading is used as the input, the output is calculated PWM duty cycles and the setpoint will be entered by the user. In addition, the library requires that the user define or supply the tuning parameters. These are the proportional gain Kp, integral gain Ki and derivative gain Kd. The controller's behavior is determined by these gains. In Section VII, we discuss tuning in greater detail.

D. The importance of tuning parameters (Kp Ki Kd) and the basic methods

Tuning is the key to achieving good performance with PID. The tuning parameters Kp, Ki and Kd determine the aggressiveness of how the controller reacts to error. Stability and accuracy are dependent on finding the best values. The system may be slower to react if Kp is low. It could also have steady-state errors. If Kp becomes too high, it can cause the system to become unstable and oscillate around its setpoint. Ki can cause instability and oscillations if it is too high. This happens especially when temperatures are low. A steady state error will be left if the value is too low. If Kd is too high it can cause noise, but if it's too low then there may be insufficient damping. Although there are a number of tuning techniques, no single method fits all. Ziegler Nichols Method: An approach that involves finding the ultimate gain of a system and its ultimate cycle time. On the basis of these values, simple rules are applied to determine initial Kp and Ki. It is difficult to use this method in the real world as it can cause instability.

1. The most popular method of implementation is "Try-and-Error". This works best with a PID Library. This process begins with an initial guess for Kp and Ki and observes the response of the system to a change in setpoint. The gains are then adjusted based on observed behavior (e.g. using the Arduino Serial Monitor, to view PV, SP and calculated output). It is important to have a fast and stable response (minimal oscillations, minimal overshoots, small steady state error). This process involves tuning Kp and setting Ki to zero, followed by adding integral action and, if necessary, derivative action.

E. The duty cycle is scaled to fit the Arduino PWM range (0-255, for the majority of PWM pins).

PID libraries calculate the output control, which is often displayed as a range of values that may be far outside the range of 0-255 suitable for PWM on many Arduino boards. To produce the control signal, PID sums the I and D terms (e.g. the desired duty cycle for PWM). The calculated value must be scaled so that it fits the range of 0-255. It is as simple as this: PWM_value = maps(PID_output) lower_bound and upper_bound (0, 255);, where PID_output represents the value calculated from the library. lower_bound, and upper_bound, define the output range. The PWM_value resulting from this is written using analogueWrite(pwmPin and PWM_value);. The duty cycle is used to control the SSR which, in turn, controls the power delivered to the heater element.

F. SEO Focus: Keywords like "Arduino PID code," "PID library arduino," "tuning PID Arduino," "sensor reading Arduino," "Arduino PWM output. "

IV. Installing Hardware and Connecting Components

A. Schematic Overview Diagrammatic representations of connections: (Sensor-> Arduino, Arduino->Heating Element via SSR & PWM, Power Supply considerations).

A detailed schematic is not possible in this text. However, an overview of the concept is useful. Sensors are connected to analog and digital input pins on Arduino. The Arduino PWM pin is connected to the SSR's input. SSR output terminals are connected to power source (voltage and ground), and heating element. Arduino needs a power supply that matches its voltage (typically, 5V or DC 12V). As a precaution, a fuse must be installed on the line that supplies power to the SSR/heating elements. You may want to consider basic protection, such as a capacitor placed across the SSR's terminals. Online, you can find diagrams for certain sensor/SSR combination.