Overview of the Article: PID controllers and Temperature Control

I. Introduction:

The importance of temperature control for various industries, including manufacturing, chemical processing, food production, laboratories, and HVAC.

Statement of the Problem: The challenges in achieving a stable temperature and accuracy without using advanced control methods.

The PID controller is the best solution for precision control.

This article explains what PID temperature controllers are, their benefits and the way to use and adjust them.

The following keywords are used to target the PID controller: Process control, temperature control, precision temperature control.

II. What is PID controller? The Foundation

III. What is the Mechanics of a PID controller?

The temperature application: Identify the process (heating/cooling systems) and the goal.

* Components of the System: Identify and describe each component - sensor (thermocouple or RTD), controller (hardware/software), actuator (heater valve chiller)

This is the Control Loop Sequence. It outlines each step (Read, Calculate Error, PID Calculation and Determine Output).

The loop's goal is to achieve and maintain a desired setpoint temperature with minimal deviation.

The following keywords are used to target the research: temperature control system, sensors, controllers, types of actuators, process variables, setpoint, and PID calculations.

IV. Why choose a PID controller? What are the benefits and advantages?

* Greater Accuracy: Describe the reduction or elimination of error in steady state compared with simpler methods.

Discussion of faster response time and reduced overshoot because the derivative component.

* Process Stability - Describe the smoother and more stable operation that PID controls provide.

* Applicability and Versatility: Mention the wide range of industries that it is used in.

Refer to its position as an essential tool for modern industrial control.

Compare and contrast the alternatives: Briefly describe their limitations.

* Target Keywords: Temperature control accuracy, PID advantages, process stability, overshoot minimization, steady-state error reduction, industrial control standard, bang-bang control comparison.

V. Implementing the PID controller

Please describe briefly how components could be integrated into a system as simple as an oven.

Key words: controller configuration, PID implementation and temperature sensor integration.

VI. Tuning The Controller: Critical Art and Science

The importance of tuning: Stress that the Kp (Proportional Gain), Ki, (Integral Gain) and Kd, (Derivative Gain), are crucial to performance.

Discussion of tuning challenges: How incorrect tuning may lead to oscillations, instabilities, and excessive wear of the actuator.

* Common tuning methods: Explain trial and error (Ziegler Nichols as an example), automated tunning, and analytical approaches.

* Tuning objectives: Describe the balance of speed, minimization overshoot and steady state error.

Mention briefly considerations such as filtering noisy signals.

* Target Keywords: PID tuning process, Kp Ki Kd parameters, tuning methodology, Ziegler-Nichols tuning method, PID parameter optimization, system response optimization.

VII. Reality Check: Limitations and considerations

Discussion of non-ideal factors, such as sensor noise, actuator saturation, inaccuracies with system models, and delays during implementation.

* Complexity of the process: Mention highly complex or nonlinear processes that may need more sophisticated control strategies.

Please note that high-speed computing may be required for very rapid processes.

Please briefly mention the importance of periodic calibration for sensors and controllers.

* Keywords to be targeted: nonlinear process, controller complexity, nonlinear PID, model inaccuracies and delays, modelling errors, system delays.

VIII. Conclusions: PID control has a lasting value

Now, the Complete Article Draft:

Note: This text has been formatted to make it easy for you to copy and paste into Word. The headings have been structured to allow for Table of Contents creation. )

Understand and implement PID controllers for temperature control

I. I. Introduction

persistent errors called steady-state errors. This is where the Proportional-Integral-Derivative (PID) controller emerges as the dominant and highly effective solution. The article explores the fundamentals, benefits, application, and considerations when using PID controllers to control temperature, which is a key technique in modern industrial automation. PID controllers enable engineers to create, optimize, and implement temperature control systems that are unmatched in precision.

II. What is PID controller? The Foundation

A PID controller, at its heart, is an closed loop feedback mechanism that automatically adjusts a process parameter (PV), to a setpoint desired (SP). This is achieved by continuously computing an value which represents the difference between the setpoint (SP) and the PV measured. This controller is unique in its ability to calculate this error, and then apply corrective actions based on the three terms that are complementary:

The proportional control (P) component: This part reacts to the magnitude in the error. The P-term output is directly proportional to error, and is calculated by Output_P=Kp*Error where Kp represents Proportional Gain. Higher Kp leads to larger corrections for any error. This results in an initial response that is faster. If Kp is set too high, however, it can cause the system to become sensitive, and the oscillation around the presetpoint. The P-control alone leaves a residual error or steady state error which can be undesirable for many precision applications.

Integral Control (I): The term is used to describe the steady-state errors left behind by P controls. The error is accumulated over time and the I term reacts by adding up past errors. The output is proportional the the integral error. This is calculated by: Output_I= Ki*(Error), where Ki is the Integral Gain. This component continuously corrects outputs to remove any difference that persists between setpoints and measured values, reducing the error. It is therefore crucial to achieve long-term accuracy. However, if I control is not balanced properly it can cause instability.

Control (D) Derivative: The component reacts to the change rate in the error. The component predicts future potential errors by analyzing how fast the error develops. The output is proportional with the rate of error change, and is calculated by Output_D=Kd* d(Error/dt), where Kd represents the Derived Gain. The D term anticipates changes and allows for the controller to take corrective actions before temperature deviates significantly from setpoint. This reduces overshoot, dampens system oscillations, and minimizes the deviation of the setpoint. Derivative action, however, can be affected by measurement noise and could potentially increase unwanted fluctuations.

This combination is what gives a PID control its true power. Engineers can create a fast, stable and robust control response by tuning Kp, Ki, or Kd to their specific needs.

III. What is the Mechanics of a PID controller?

When applying a PID to a system of temperature control, you are managing a "process".

The controller is controlled by a loop that consists of key components which work together:

Sensor Measures the temperature of an object (PV).

Controller: The "brain" is . The controller can be a computer, a PLC, a microcontroller or a special hardware device. The controller compares the temperature reading from the sensor to the set point defined by the user, calculates any errors, then uses the mathematical algorithms of the PID algorithm to find the signal.

The Actuator: It receives the signal of the controller, and then adjusts to the desired temperature. For example, you can modulate the cooling fluid flow (using a valve to control chilled water flow) or adjust the power delivered to the heating element. Actuator action reduces the error calculated by controller.

Control loops are continuously active, usually in rapid feedback cycles.

Read The sensor is polled to determine the temperature.

Calculate error: When the controller calculates an error, it will use (Error = PV - SP).

Calculation of PID: The controller uses the error value and the historical values for I and D to calculate the components P, I and D using the formulas that involve Kp, Ki and Kd.

Determining Output: By adding the components P, I and D, the controller produces a single output control signal. The signal will be scaled to the actuator's specific size and format.

Actuate An actuator is a device that receives a control signal, and then adjusts it's action to move the temperature toward the presetpoint.

Loop continues: This process is repeated from the first step, creating a feedback loop that strives to minimise error.

The temperature is adjusted continuously to ensure that it remains close to the set point, compensating any disturbances. This maintains process stability.

IV. Why choose a PID controller? What are the benefits and advantages?

PID controllers are widely used for temperature control because they offer a number of benefits that other control methods cannot. The synergy between the terms P, I and D allows for an optimal control system.

High Accuracy Integral is a powerful term in this respect. It actively eliminates the steady state error, which is a problem with simpler control systems such as on/off and proportional. The process temperature will be much closer to its exact setpoint. This is important for applications that require high precision such as pharmaceutical formulas or semiconductor manufacturing.

Improved Dynamics and Reduction of Overshoot: Derivative D provides a forward-looking Control. It anticipates temperature changes in the future by adjusting to the rate at which the error is changing. It reduces overshoot, the extent of the temperature exceeding the setpoint as it approaches, and dampens oscillations. This leads to smoother transitions between setpoints.

Process stability: The PID controls excel at maintaining process stability. A well-tuned loop of PID provides stable responses compared to hunting behavior of proportional controls or slow settlement of on/off controls. This loop can counter minor disturbances effectively without causing large fluctuations. It ensures consistent conditions in the process.

Versatility: PID's fundamental algorithm structure is highly adaptable.

Reliability and Established Standard: Years of research, design, and application in the field have made PIDs a reliable standard for industrial automation. The control system manufacturers offer a large library of PID blocks pre-configured for DCS and PLC platforms. This ensures reliability and easy implementation. The widespread usage of PID blocks means that there is a large pool of resources and expertise for optimization and troubleshooting.

Compare with Alternatives: Simplicity Bang-Bang Control The classic thermostat (which switches between completely on and off) can be too crude and lead to temperature fluctuations and inefficiency because of the cooking effect. Pure proportional control is prone to the steady-state errors mentioned above. Other advanced control strategies, such as fuzzy logic and model-predictive control, are available for complex systems or nonlinear ones. However, for many temperature control applications, PID provides a good balance between performance, simplicity and cost effectiveness.

The PID controller is a powerful, precise, and reliable tool for controlling temperature dynamics. It's the ideal choice for industrial and commercial applications that require accurate thermal regulation.

The PID controller in practice

To ensure that the PID controller functions correctly, it is important to consider both software and hardware aspects. Theoretically, the principles of PID are clear. However, the success of implementation depends on choosing the right components and correctly configuring the controller.

Core Hardware Components.

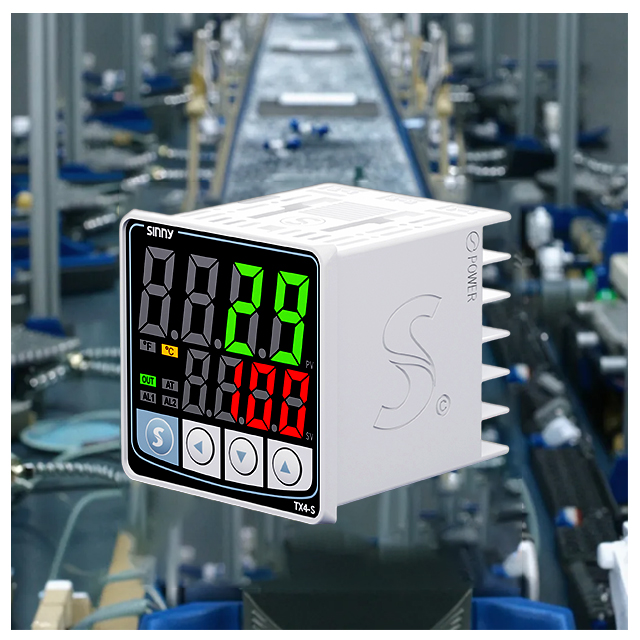

- What Does A Digital Temperature Controller Do?

- The PID control for temperature: principles, implementation & tuning