process of setting up a pid temperature controller - Problem explanation

1. Basic process type

What functions do temp control generally have?

We know that thermostats usually have the functions of both cooling and heating. Some thermostats only have the heating function. The core purpose of using thermostats is mainly to accurately measure the temperature of the equipment or the ambient temperature to the target value you desire. The sensors that sense temperature are generally connected to the temperature controller. They notify the temperature controller of external information through the mode of transmitting information and then control it through the control instructions of the temperature controller

1. Refrigeration addition - Set the upper and lower lines of the temperature

Generally speaking, the default temperature controller at the factory is set to heating mode, with the heating mode being the reverse action and the cooling mode being the forward action. Both heating and cooling have certain practicality in different devices

How do I turn on the heating or cooling?

Take our sinny product as an example. Press and hold the S key at this time, the interface will display the P-1 screen. By clicking the up key, adjust P-1 to the p-2 screen. Then click the S key to enter the parameter menu. Click the S key continuously 11 times, and the screen will display HC. In this way, the heating and cooling operations can be modified normally. The final step is to adjust the up and down keys and then press the S key for 3 seconds to enter the "Confirm Parameters" menu. Here, we can adjust the upper and lower limit values of SV to ensure the accuracy of control

How to adjust the upper and lower limit values of SV?

The main purpose of adjusting SV is to prevent the temperature equipment from exceeding the temperature range, ensure the overheating and damage of the product, and also avoid the damage to the product caused by someone's adjustment

When the input specification is a thermocouple of model K, the lower limit of SV(set value) is not less than 100°C, and the upper limit is not allowed to exceed 600°C.

To avoid burning out, do not exceed the range that the thermocouple can withstand

2. How to adjust the basic control: Hysteresis in ON/OFF mode, switching input and output

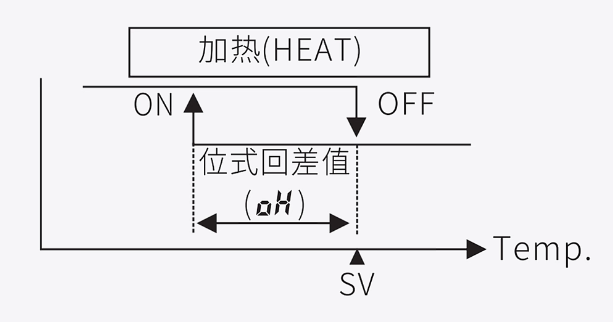

Hysteresis: A buffer period between the actual value and the current value adjustment

Input and output: TC, RTD and relay ssr are selectable

The bitwise hysteresis value can only be set when the control mode is ON/0FF

If the hysteresis amplitude is too small, unstable control output may occur due to external interference and other reasons

The input is the sensor and the output is the heating tube. If the input needs to be changed, for instance, if the thermocouple is replaced with a PT100, the temperature controller must be restarted after the replacement to ensure the accuracy of the temperature reading

Note: When carrying out these operation steps, it is necessary to have everything from preparatory work to parameter setting, confirmation of target values and actual values, installation and debugging of wiring, setting of basic parameters of the instrument, and also learn to observe

3. Basic questions

How to solve the problem of low temperature accuracy

2. What is the working process of the temperature controller?

3. What is the PID value?

4. How to effectively adjust PID parameters

First, calibrate the temperature to observe if it deviates. Then, adjust the PID parameters to stabilize the temperature. Next, check for component issues and sensor problems. Finally, test the ambient temperature to see if it has an impact

2. The controller forces the temperature to be stabilized within a range of the set value by calculating the difference between the set temperature value and the designed temperature value

3.PID:P stands for proportion, I for integration, and D for differentiation. The combination of the three forms the PID algorithm

4. The sensor information is collected and transmitted to the temperature controller. The temperature controller issues instructions through the general PID algorithm, which are then transmitted by the sensor, and finally the adjustment is completed