Setup, Tuning & Industrial Solutions for PID Temperature Controllers

Learn how to master PID temperature control. Includes a step-by-step guide for tuning, the best controllers for ovens/3D printers and case studies of industrial implementation.

I. I. Introduction to Precision Temperature Domination

To comply with FDA requirements, industrial sterilization autoclaves require stability of +-0.5degC. This is not possible with conventional thermostats. Unlike basic on/off controls exhibiting +-5degC fluctuations, PID (Proportional-Integral-Derivative) algorithms dynamically modulate power through continuous error computation, reducing energy consumption by 18-30% according to Department of Energy 2023 findings. The mathematical controllers turn thermal instabilities into precise instrumentation. This is especially important for semiconductor production, where even a 0.1degC difference can result in the scrapping of $500k worth of wafer batches.

Authority Refer: Instrumentation Standards (ISA-5.1) for Industrial Control Validation

II. PID Control Core Mechanics

1. P-Action (Proportional)

The proportional component produces an immediate correction that is proportional to the magnitude of error. For instance, a 10degC temperature deficit might trigger 80% heater power. Insufficient gain can cause a sluggish reaction, but excessive gain will result in dangerous oscillations. Control Guru simulations show that the initial setting for stable operation should be close to Process Gain.

2. Integral Action

By accumulating past errors, integral action removes persistent steady state offset. I-time, measured in minutes/repeat as the inverse of reset rates (the process dynamics), must be calibrated. According to ISA-77, the optimal I-time is 3 x the process dead-time. Importantly, disabling integral action is crucial when controlling valves on/off to avoid destructive windup.

3. Derivative (D) Action

The derivative functionality calculates the rate of change in error (dE/dt) to predict future deviations. This adjustment reduces the overshoot in rapid heating phases. To avoid the amplification measurement artifacts, you should suspend any derivative actions in environments where there is >1% noise.

III. PID vs. On/Off Thermostats: Performance Benchmarks

Metric PID control Thermostat Turn On/Off Industrial Impact

Temperature stability +-0.1-1degC +-3-10degC Avoiding batch rejection of pharmaceuticals

Energy Efficiency Reductions of 18-30% Cycling losses Savings of $45k/year on 500kW ovens

Lifespan of Equipment Relay longevity 2.3x Contact Wear Reduction in maintenance costs by 32%

Process Compliance ISO 9001:2008 Certified Validation fails Avoids FDA audit penalties

Source: Omega Engineering Comparative Analysis

IV. Top 5 PID Controllers by Application

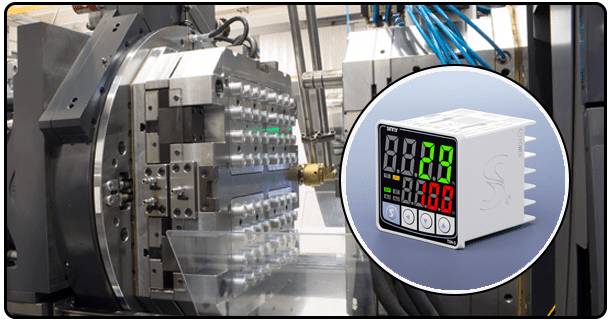

1. Industrial Kilns & Ovens

Watlow Model :

Feature 32-segment Recipe Programming with SPC Data Logging

Validated settings (per Ceramic Industry Journal). P=4.2 min., I=8 minutes, D=1.

2. Additive Manufacturing

Model : Duet 3.

: Real-time Extrusion Control with 100kHz Sampling

Settings: P=22, I=1.2 min, D=0.1

3. Food Processing

InkBird Model ITC-308

Features: Dual SSR 15A outputs for Heating/Cooling

Settings: P=7, I=5 min, D=0

4. Lab Applications

Model: Omega CNi3254

Feature: NIST-traceable calibration certificates

Settings: P=3.8, I=12 min, D=0.5

5. Building Management Systems

Model: Siemens PX876

Feature: Modbus/BACnet integration

Settings: P=1.5, I=0.3 min, D=4

V. Step-by-Step Implementation Protocol

Phase I: Hardware Configuration

Stage Power: Use opto-isolated ssrs when loads are >10A. (NEC compliance 430.122)

Sensing RTDs or Type K thermocouples.

Safety: Independent over-limit controllers (ANSI/ISA-84.00.01)

Phase 3: Tuning Methodology

Use relay auto-tuning to calculate ultimate gain (Ku), oscillation period, and other parameters

Use the Ziegler-Nichols Formula:

Fu Zhi Dai Ma P = 0.6Ku I = Pu/2 D = Pu/8

Validate using a 5% change in the setpoint; optimize with 1/4 decay

Phase 3: Anti-Windup Configuration

Use back-calculations to limit integral accumulation

error

VI. Industry-Specific Tuning Protocols

1. Extrusion of Polymer

Challenge : Viscosity Changes with Barrel Temperature

Solution : Adaptive "P-gain": P = 8 + 0.05T (degC).

Plastics Today : BASF reduces scrap by 31% ( Results ).

2. Heat Treatment Furnaces

Challenge : Thermal lag

Settings: P=2.1, I=22 min, D=0

Cascade Control with Inner Thermocouple Loop

3. Biotechnology Incubators

Settings: P=12, I=0.8 min, D=0.3

Protocol for Calibration: Verification of boiling water and ice point (0degC).

VII. Advanced Optimization Architectures

1. Cascade Control

Structure : Master PID(chamber)-Slave PIDs (heater current).

Parameters :

Slave: I = 0.05, P = 0.8 (fast response).

Master: I=1.2, P=3.5 (slow correction).

Application: Glass tempering (+-3degC uniformity)

2. Feedforward Compensation

Function : Preventive adjustment of measurable disturbances

Algorithm Output_ff=K_ff * (dT_ambient/dt).

3. Fuzzy Logic Adaptation

Implementation : rule-based gain adjustments for nonlinear Systems

Effectiveness: 63% faster stability in ceramic kilns. ( IEEE Transactions).

VIII. Troubleshooting Matrix

Symptom Root Cause Corrective Action

Temperature offset Integral windup Reduce I-time by 30% when clamping is enabled

Cyclic oscillation Over-P-Gain Reduce P to 25% and enable D=0.5

Slow Disturbance Recover Conservative Gains Reduce I-time by 40%; increase P time 20%

Control chatter EMI Interference Install the ferrite cores and enable moving average of 2 seconds

Referencing Control station Diagnostic Protocols

IX. Emerging Technological Innovations

AI Tuning Siemens PID4.0 utilizes neural networks to optimize gain in real time

Wireless IoT Controllers: Phoenix Contact with Cloud-based Analytics

Digital Twins : Rockwell Studio 5000 Simulation for Pre-Deployment Validation

X. Conclusion: Engineering Thermal Perfection

PID controllers convert volatile thermal processes through constant mathematical correction into precision instruments. Implement cascade architectures that are validated to ISA-5.1 standard for mission-critical applications. Omega CNi3254 is a NIST traceable controller that can be used in industrial applications. Entry-level systems such as InkBird are sufficient for simple applications. IEEE Control Systems Magazine confirms that properly-tuned PID loops can reduce energy costs by up to 22% and eliminate nonconformances.