The PID parameters for temperature control: tuning guide & industrial applications

Learn how to tune PID temperatures: Ziegler Nichols methods; application-specific parameters for ovens and reactors (such as those used in a nuclear power plant); MATLAB optimization; and troubleshooting oscillations. Included are industrial case studies.

I. I. Introduction to the Precision Balancing Act

In industrial processes such as semiconductor manufacture, stability is required. Suboptimal PID parameter values can lead to catastrophic wafer failures of $500k. The three variables (Proportional Integral Derivative), form a mathematical structure that corrects temperature errors through continuous error calculations. According to International Society of Automation, properly tuned PID circuits can reduce energy loss by up to 18% for thermal systems and prevent hazardous oscillations within exothermic reactions ( ISA 88 Standard).

II. The Core Parameters of PID Decoded

1. Proportional Gain

Function : Produces corrective output that is proportional the instantaneous mistake (e.g. 10degC deficiency - 80% of heater power).

Risk: Excessive gain induces destructive oscillations; insufficient gain causes sluggish response

Rule Of Thumb Initial Setting = 100%/Process Gain ( Control Guru).

2. Integral Time I

Function Eliminates persistent off by adding historical errors

Unit: Minutes/repeat (reset rate inverse)

Constraint : Disable on/off valves in order to avoid windup

3. Derivative Time (D)

Function : Calculates future errors based on rate of change (slope).

Limitation of Application: In noisy environments, the signal is suspended (over 1% variance).

III. Tuning Methodologies Compared

Method Error Tolerance Process requirements Industrial Case

Ziegler-Nichols +-5% оа инормаии Packaging machines

Lambda Tuning +-2% Time constants that are known HVAC chillers

IMC +-1% First-principles model Pharmaceutical reactors

Auto-Tune Relay +-0.5% Baseline operation with stable baseline Semiconductor furnaces

Source: Control Global Tuning Benchmark Study

IV. Application-Specific Parameters

1. Slow-Response Systems (Kilns, Ovens)

Typical settings: D=0, P=3-8 and I=5-15 minutes

Rationale: Thermal inertia negates derivative action

Validation : Ceramic Kiln Stability improved from +-15degC - +-2degC when P=5.2 and I=8 minutes ( Ceramic Industry Journal).

2. Fast-Response Systems (Injection Molding)

Typical settings : P=15-30 min, I=0.10-0.5 min, D=1-3

Critical Adjustment: Derivative dampens overshoot during rapid heating

3. Nonlinear Processes: Exothermic Reactors

Strategy: Gain scheduling with temperature-dependent parameters

Formula: P(th) = 10 - 0.02th (th = temperature in degC)

V. Step-by-Step Ziegler-Nichols Tuning

Closed-Loop Protocol:

Set I=0 and D=0 to disable I-D actions

Increase P incrementally until oscillations are sustained

Record:

Ku

Pu

Calculate:

P = 0.6 x Ku

I = 2 / Pu

D= Pu / 8

NASA Technical Memorandum No. 112868

VI. Advanced Optimization Techniques

1. Cascade Control Architecture:

Inner Loop Flow/Temp: P=0.8 and I=0.05 min

Outer Loop Master Temp: (P=4.2 min, I=2.1 minutes)

Application: Glass tempering furnaces requiring +-3degC uniformity

2. Anti-Windup Compensation:

Back-Calculation Formula: I_adjusted = I_raw / (1 + K_aw x error)

Prevents integral saturation during output limits

3. Noise Filtering:

First-Order Lag: t_f = 2 x (noise period)

Caution: Over-filtering introduces dead time

VII. Troubleshooting Guide

Symptom Root Cause Corrective Action

Oscillations Over-P-Gain Increase D by 25% and reduce P by 25%

Persistent offset Not enough I-action Half integral time

Recovery from Slow Disturbance Conservative P Increase the P from 15-30%

Control valve Chatter High D with Noise Implement moving average filter by disabling D

Control Station Diagnostic Handbook Authority Reference

VIII. Software Tools & Calculators

MATLAB PID Tuner: Gradient descent optimization for MIMO systems

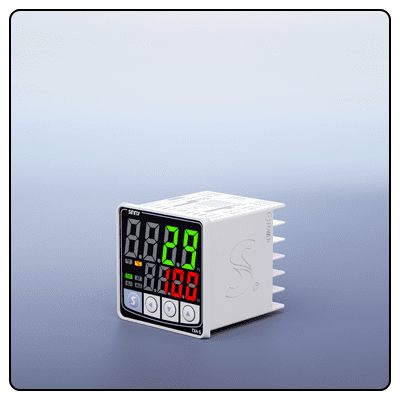

Omega iSeries : cloud-based autotuning and NIST traceable calibration

Free Online Simulator: PIDLab Interactive Tool

Rule of Thumb Calculator :

matFu Zhi Dai Ma P_initial = 100 / Process_Gain; I_initial = 3 * Process_Dead_Time;

IX. Conclusion: The Art of Scientific Tuning

For precise temperature control, it is important to match PID parameters and process dynamics. Slow thermal systems require aggressive integral actions while rapid-reacting processes need derivative dampening. Implement cascade control, with anti-windup, for mission-critical systems, and validated to ISA-88. ControlGlobal highlights that continuous loop performance monitors reduce energy costs in thermal systems by 12-22%, turning theoretical tuning into quantifiable operational excellence.

- How to wire a PID temperature controller: diagrams, safety & step-by-step guide

- PID Smoker Control Guide (2024): Setting up, tuning & best models