Temperature difference controller - A Comprehensive Guide

In the field of temperature control, single-point temperature controllers often fail to meet complex scenarios. For instance, many industrial and mechanical devices require simultaneous temperature monitoring of multiple points. As a temperature control system with two monitoring points, the temperature difference temperature controller precisely fills this gap and has become an important component for safety protection in many industries. Next, in this article, we will explore the differences between temperature difference controllers and traditional temperature controllers, as well as the practical dimensions of multi-scenario applications, interpret the problems that a single temperature controller cannot overcome, and provide valuable technical references for temperature control in different fields.

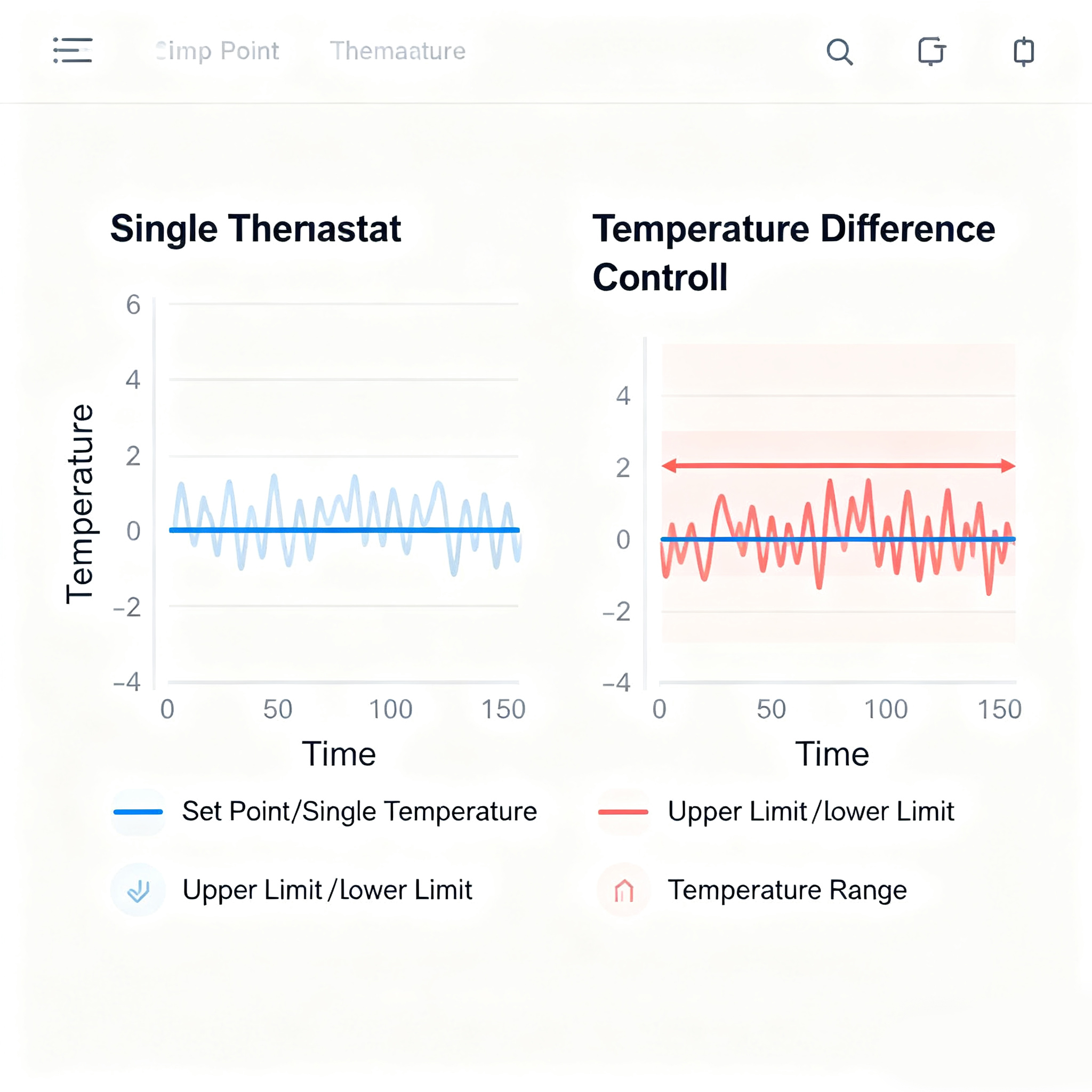

difference between a single temperature air controller and a temperature difference controller:

A single temperature controller has only one sensor inside to monitor one temperature point, so it can only monitor the temperature of one point.

2. The temperature difference controller is equipped with two built-in sensors or can be connected to two specific sensors externally, which can measure the temperature at two points respectively.

3. Control logic: The temperature difference thermostat is triggered based on the "temperature difference threshold", and a single thermostat is triggered by a "single temperature threshold".

Product technical parameters that must be considered when selecting a model

1. Temperature difference range The common temperature monitoring range of thermostats is 0 to 50℃, which depends on your temperature control accuracy. The more industrial-grade the equipment, the more precise the temperature control instrument is required.

2. Temperature measurement accuracy: Generally ±0.1 to ±0.5℃, which serves as the measurement error of the sensor

3. Output signals: Mainly relays, analog quantities, and SSR outputs.

4. Power supply voltage: Generally, it is 220vfor household use and 380v for industrial use (for high-power electrical appliances).

5. Adjustment methods: Knob adjustment, key adjustment, and remote adjustment mode via AP

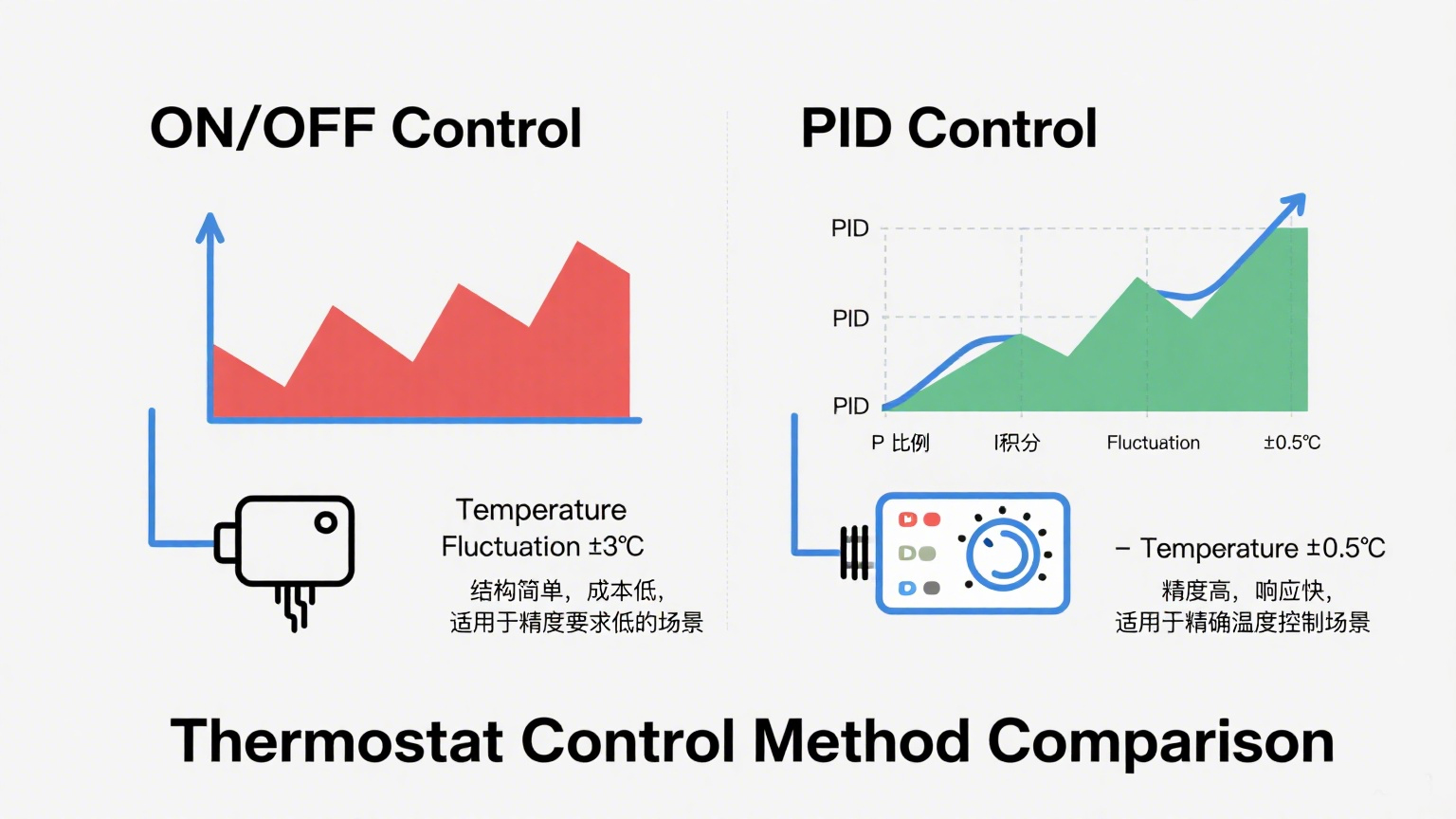

Different types of control logic thermostats

1. Switch temperature difference control logic: By outputting "on" and "off" output signals, it controls the threshold range of temperature. It is suitable for a single scenario, has a relatively low cost, and is highly practical.

2.PID temperature difference controller: Through the PID algorithm, it dynamically adjusts the output at a rapid change rate based on the magnitude of the temperature difference deviation.

working process of the temperature difference controller

1. Temperature collection - temperature difference calculation ----- threshold judgment ----- dynamic adjustment -------- status feedback

Note: The temperature is collected by the sensor, the temperature difference threshold is calculated and judged by the microprocessor, and the dynamic output adjustment is made. Finally, the actual detection and observation data are obtained.

Compared with traditional thermostats, the irreplaceable nature of temperature difference controllers

The temperature difference temperature control processor and sensing elements are superior to those of traditional temperature controllers. Therefore, in terms of processing response, the temperature difference temperature controller is higher than the traditional single temperature controller.

2. The temperature difference controller has two monitoring points. Due to the fact that the data linkage effect is higher than that of a single monitoring point, the temperature difference controller has more advantages in measurement.

3. Traditional thermostats are more suitable for some household and small-scale scenarios, while temperature difference controllers are applicable to industrial equipment temperature difference balance, cold chain anti-frosting, medical environment temperature difference protection and other devices.

Case: For a traditional thermostat installed inside a refrigerator, with a temperature modulation of -18℃, the surface of the thermostat drops to -18℃, but the interior of the refrigerator may be -17℃. Due to the increase in temperature, the product may thaw

For differential temperature controllers: There are 2 temperature measurement points (2 sensors), and the thresholds (T1 and T2) of the 2 points can be monitored respectively.

The difference between T1 and T2 is Δ T. The two are adjusted in coordination to keep the temperature range always within the required threshold range, achieving equilibrium

The application fields of temperature difference controllers

1. Industrial equipment: In the production process of products with heating and cooling, such as clinker extruders, there are two monitoring points in the heating section and cooling section for monitoring. The difference between T1 and T2 is compared by distribution to ensure that the system adjustment neither exceeds the upper limit value nor falls below the lower limit value

2. In the medical field: The temperature difference between the equipment and the external environment. Newborn babies need an appropriate temperature in the incubator. If there is only one temperature controller, a sudden drop in the indoor temperature controller will cause an imbalance between the temperature inside the training incubator and the indoor temperature, which can easily lead to the baby catching a cold. Therefore, a temperature difference controller with two monitoring points must be used to monitor the temperature and issue early warnings. Doctors can adjust the temperature in a timely manner based on the data from the two monitoring points.

Conclusion

The value of a temperature difference controller lies in addressing the temperature difference issues of equipment that requires multiple monitoring points. First, you need to clarify whether your requirements include this type of temperature controller (specifying the temperature range, accuracy, and temperature control processing speed). Based on these problems, a single temperature controller can no longer meet your goals, and you can only choose a temperature difference temperature controller. However, if it is for household use, a single thermostat is sufficient (low cost and high cost performance).

- How to set pid values in temperature controller

- Why does your PID always go out of control? These optimization "pitfalls" must be avoided