Why does your PID always go out of control? These optimization "pitfalls" must be avoided

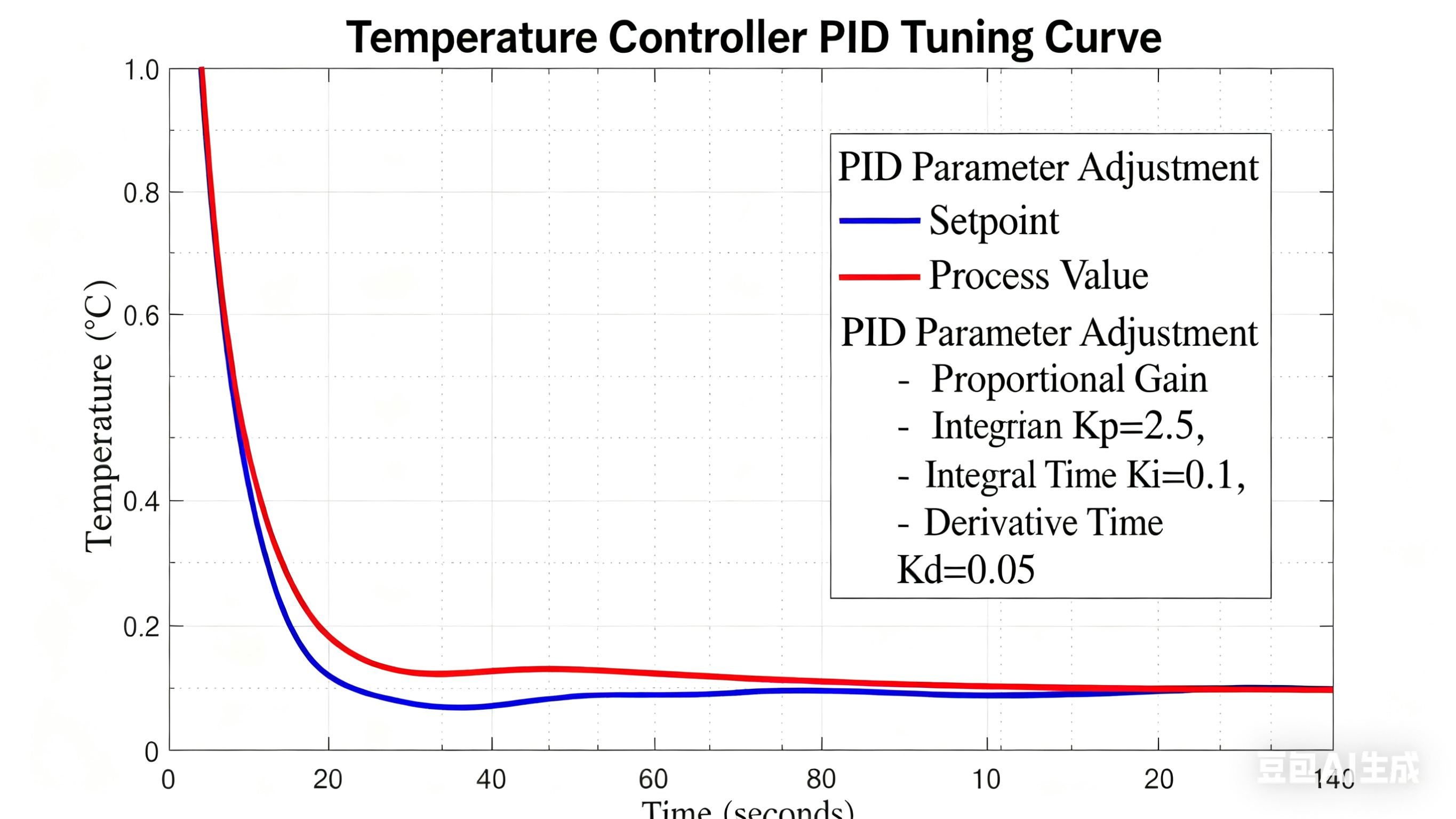

The core of PID tuningis to first understand the logic of the controlled object, then adjust the parameters in sequence, and subsequently use the PID algorithm to assist in judgment (stable and precise control)

1. Adjust the parameters directly without looking at the equipment

If you directly input the P I D value without understanding the characteristics of the controlled object, the system is prone to losing control.

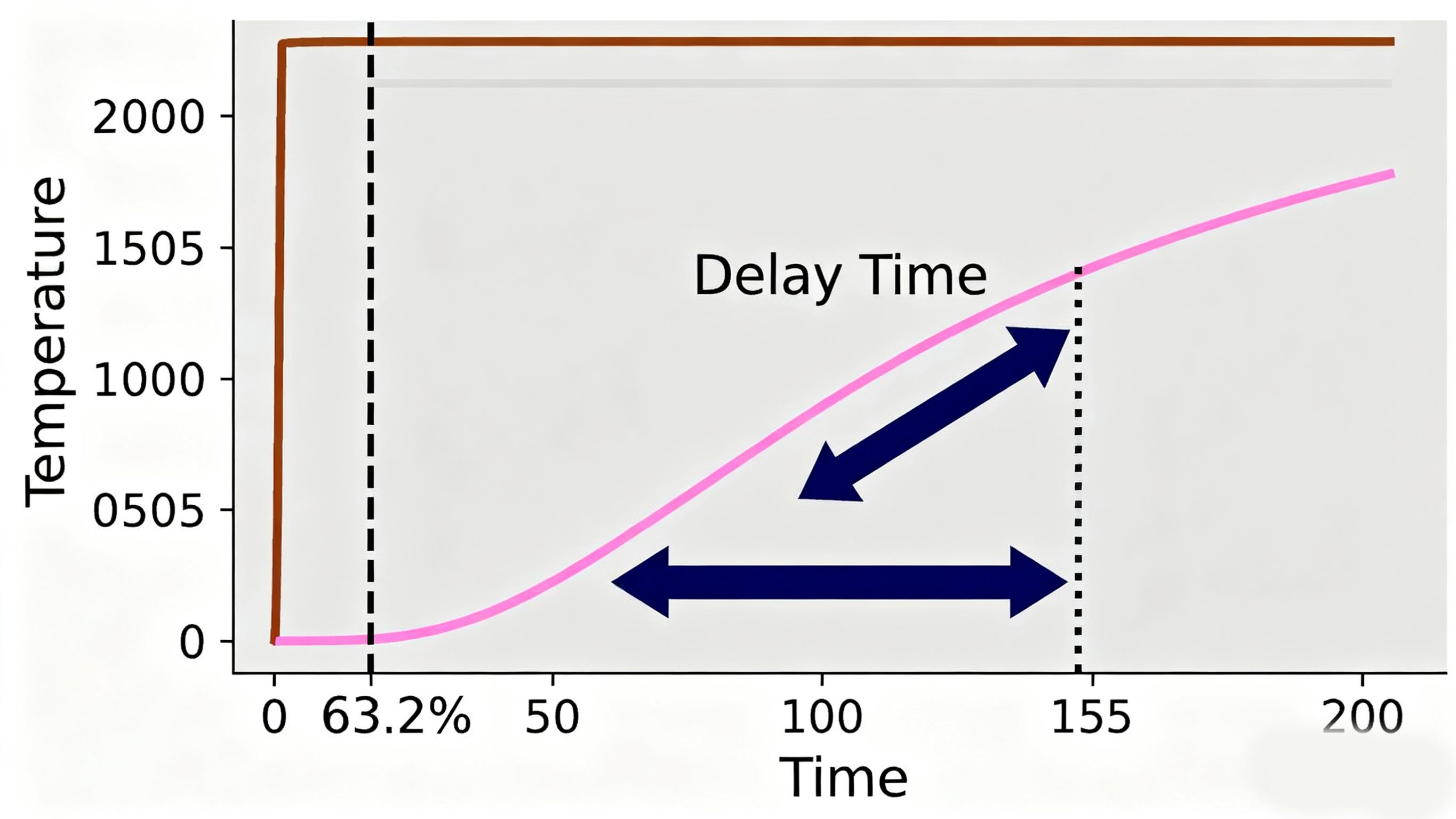

The essence of PID is to adjust parameters reasonably based on the controlled object. First of all, an open-loop test must be conducted before the adjustment to obtain the parameters of the controlled object

1. Give the system a stage input, for example, for the transition from 20℃ to 40℃, use one input

2. Record the output curve to obtain the lag time, time constant and changes in gain value

3. Calculate the initial parameters (such as P=1.2T/(Kτ), I=2τ, D=0.5τ) according to the Ziegler-Nichols formula, and then fine-tune the results

2. Only adjusting P without adjusting I and D makes the system uncoordinated

P: Adjust according to the deviation ratio

I: Accumulate deviation and eliminate static error

D: Prevent deviation and avoid excessive adjustment

Adjusting only the P value cannot make the system coordinate and will not reach the target value

Adjustment: First adjust P, then I, and finally D

Gradually increase the p value until there is no obvious deviation. At this point, adjust the I value and observe that the static deviation decreases. Observe the overshoot phenomenon. If the overshoot is too large, adjust it slowly and do not over-adjust the I value. Finally, adjust the D value as the "brake" of the temperature control system. It determines the last step and the final link. Slowly increase the D value to suppress the over-screen phenomenon. Just keep the fluctuation within the target range.

3. Parameter adjustment is too fast and it is incorrect to achieve it all at once

Excessive adjustment of parameters can easily lead to overshoot, lag, and the system is prone to losing control. During the process of adjusting the P value, both I and D will have certain influences. We should adopt the "small-step iterative method". Each time the parameters are adjusted, the change range should not exceed 15% of the change range. Fine-tuning bit by bit, and finally finding the appropriate parameter result

4. The lagging importance of "system latency"

In a system with a delay, the process of adjusting parameters until the system is executed requires the "brain" of the thermostat to carry it out. This process will have a certain delay period. When you make adjustments, the temperature won't rise, and when you want the temperature to drop, it won't fall either.

The temperature control system - "deviation feedback is not timely", which is equivalent to you adjusting the parameters at point A, and the system only executes when it reaches point B

How can it be avoided?

Gradually reduce P and increase I, allowing the integration to accumulate data slowly and eliminate errors. The delay time is calculated based on the adjustment of P and I, and the system's delay time is directly set.

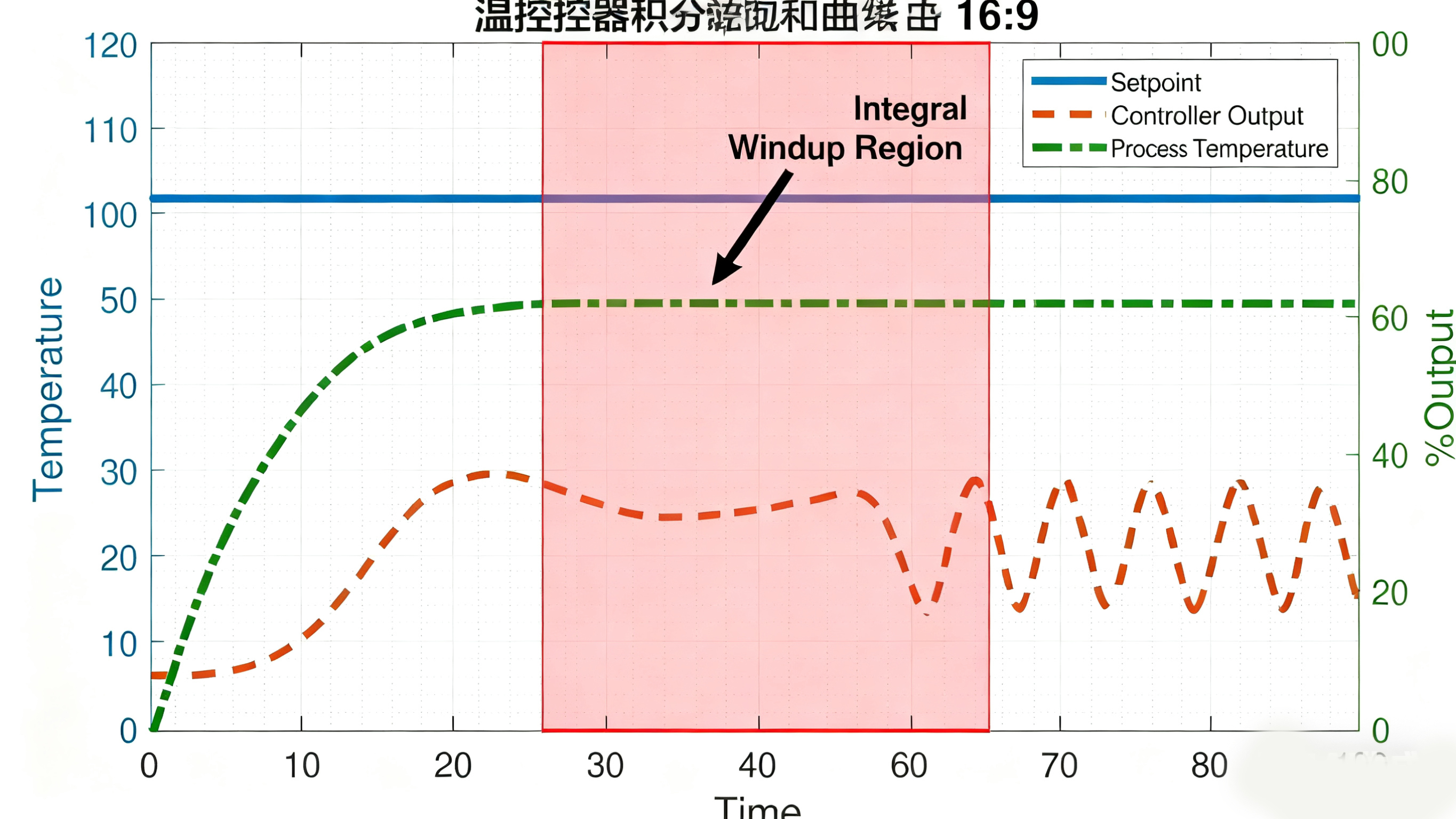

5. Confusion between "integral saturation" and "insufficient parameters"

The actuators of the temperature controller all have a maximum tolerance value. When the system experiences integral saturation, that is, the temperature keeps rising but fails to reach the desired result, this is the maximum output power of the system. If the P value is further adjusted and the temperature becomes larger and larger, exceeding the target temperature value, and the I value is further increased, the saturation will become larger and larger, deviating more and more from the target value. That is, when the deviation accumulates larger and larger, At this point, the actuator can no longer handle it. As I increases, the saturation will become larger and larger. Saturation is not caused by insufficient I.

How can it be solved?

First, it is necessary to determine whether the integration is saturated, and then decide whether to adjust the value of I

Activate the "integral separation" or "anti-integral saturation" function judgment of the controller. When the deviation exceeds 10% of the set value, pause the integration. When the deviation is less than 5%, restore the integration.

6. Over-reliance on automatic tuning and never manual adjustment

Automatic tuning is very reliable. However, when tested under different working conditions (such as when the motor is loaded with 20%, 50%, and 80% loads respectively), it may sometimes be inaccurate and manual adjustment is required. But in most scenarios, automatic tuning can solve the problem

7. Ignore "Measurement noise"

The sensor signal noise system, when the D is increased to suppress overshoot, has a large output noise and an extremely high out-of-control rate

D is for adjusting the "rate of change of deviation", and noise is for "high-frequency minor deviations". D will amplify these minor deviations, causing frequent fluctuations in the controller output and leading to loss of control.

The solution is that the noise must be addressed first before adjusting the D value

The three golden rules for Tuning

First, thoroughly understand the equipment before adjusting the parameters: The characteristics of the equipment are the root, and the parameters are the leaves. If the root is unstable, the leaves will definitely be chaotic.

Adjust step by step slowly: start with P, then I, and finally D. Change one at a time, take small steps, and remember the curve well.

Test several working conditions: Don't just look at the laboratory. All on-site conditions must be taken into account. Test them before use.

- Temperature difference controller - A Comprehensive Guide

- What is the principle of an analog temperature controller? Comprehensive Guide