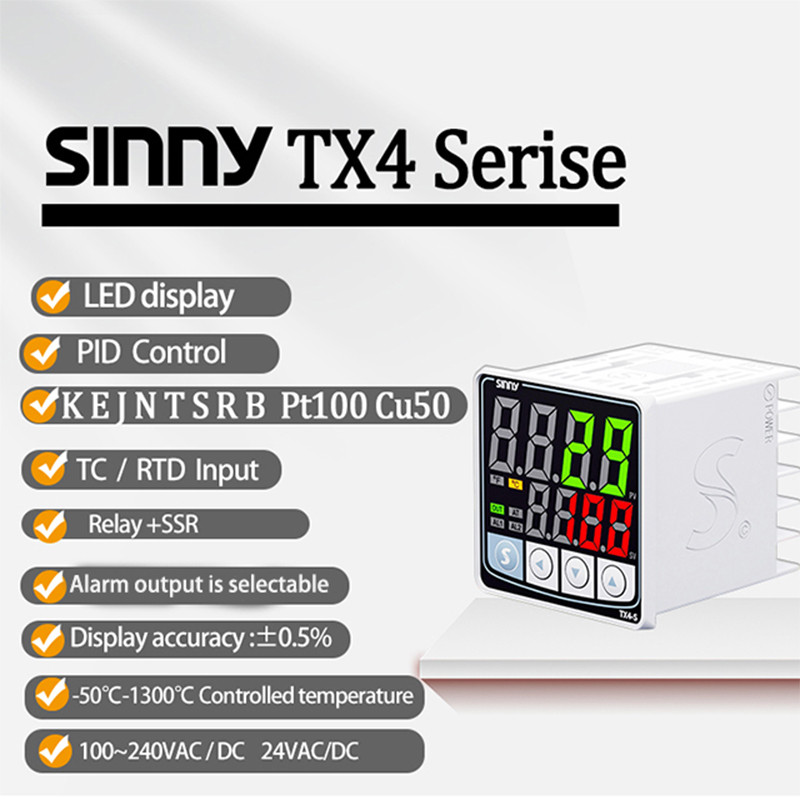

The PID SUR output: Optimize temperature controller performance & output stability

Learn how SUR in PID controllers can prevent output cycling and relay failure, while ensuring precise temperature ramps. Included are a tuning guide as well as industry applications.

1. The following is a brief introduction to the topic:

A sudden rise in temperature of only 5degC, for example, can cause delicate crystals to break, and cost millions on ruined batches. At the heart of such precision-critical systems lies the PID (Proportional-Integral-Derivative) controller--specifically its SUR (Setpoint Update Rate) output function. SUR regulates , the rate at which changes target temperatures (Set Value), directly impacting heater/cooler stability. The article discusses the role of SUR in PID controllers. It also examines its optimal output signal integrity and how it is used to prevent equipment stress or product loss.

2. Thermostats: PID and traditional thermostats Thermostats with traditional output mechanisms

The control is used in traditional thermostats. Heaters are activated at full power when temperatures fall below the threshold and then completely shut down once it's exceeded. It causes oscillations in temperature (+-5degC) of typical ovens and increases relay wear. PID Controllers with SUR, on the other hand, modulate outputs in proportion:

Power (0-100%) is continuously adjusted based on the real-time calculation of errors

SUR allows smooth transitions between setpoints. (E.g. ramping the SV up from 20degC to 150degC in 30 minutes).

Thermal shock is eliminated by eliminating output surges

Watlow’s technical analysis notes that PID systems equipped with SUR can reduce temperature variations by as much as 80% when compared to thermostatic control.

3. Demystifying SUR Output

The Setpoint Update Rate (SUR) is the rate at which changes temperature target. There are two primary interpretations:

Update Setpoint Frequency : The frequency at which SV recalculates itself (e.g. 10 times per second)

Step Up/Down Rate : the speed at which SV (e.g. 3degC/minute), transitions are made.

Critical impact

Slow-Surf: This prevents overshooting in systems with high inertia, such as industrial furnaces.

Fast Sur: Suitable for rapid response processes such as laser diode cool-down.

SURs that are mismatched can cause output devices to cycle destructively. This is similar to repeatedly slamming the brake and accelerator pedals of a vehicle.

4. SUR’s Influence on Output Signals

SUR is dynamically interacted with output hardware for stability.

Output type Impact Setting the SUR to the Optimal Level

Relay Electromechanical Limiting on/off cycle reduces contact arcing <0.5degC/sec

Solid-State Relay Reduces the thermal strain on thyristors 1-5degC/sec

Analog (4-20mA/0-10V) Current/Power Adjustments Smoothed Response time for a Matched Actuator

PWM The duty cycle is stabilized Update intervals PWM periods

Case study A ceramic kiln with relay outputs has reduced failures to contact by 70%, after setting SUR at 2degC/min. This allowed for gradual thermal expansion. Omega Engineering output guide explains signal compatibility.

5. Tuning SUR for Optimal Output Performance

SUR balances Speed with Stability.

Key Parameters :

Time to Ramp: Duration of transitioning between ramps.

Interval Update: Frequency of SV updates (e.g. 100 ms)

The tuning method :

Calculate the system's maximum thermal slewrate.

Maximum SUR (degC/min). = (Heater power [kW] / Thermal mass [kWh/degC]

Initial SUR set to 50%

Increase P/I gains by adjusting SUR

Auto SUR Features Modern controllers, such as the Omron® E5CC, detect dynamic processes to automatically configure SUR when tuning PID.

6. SUR in Real-World Applications

Pharmaceutically Lyophilization : The SUR controlled freeze-dryers increase SV by 0.3degC/min in order to avoid protein denaturement while optimizing the vacuum pump output.

Tempering : The step-down method SUR = 4degC/min allows for even cooling and avoids internal stress that can cause shattering.

Cooling for Data Centers PID controllers using adaptive SUR reduce energy consumption by 25%. ( Case Study).

7. Troubleshooting Output Issues via SUR

Output Cycling

Cause : Thermal response exceeds the system's thermal capability

Reduce the SUR time by 50% and increase the PID integral Time with Solution

Symptom : PV Unable Track SV

Cause: SUR too slow; output signals "coast" due to delayed updates

Solution: Shorten SUR update interval; verify sensor lag

Heater Alarms Overcurrent

Cause : Rapid output changes due to aggressive SUR

Solution: Enable "SUR Hold" during disturbances (e.g., oven door open)

8. Advanced SUR Features

SUR Adaptive: Adjusts ramp rates automatically based on feedback from PV (e.g. Watlow controllers when batch starting).

Multi-Segment Profiling : Programs complex SV ramps/soaks for processes like solder reflow:

Fu Zhi Dai Ma Segment 1: SUR=3degC/min - 150degC (preheat) Segment 2: SUR=1degC/min - 220degC (soak) Segment 3: SUR=4degC/min - 60degC (cooling)

Cloud Based SUR Logging : Eurotherm controllers send SUR/output logging data to Azure IoT platforms for predictive maintenance.

9. Conclusion

SUR elevates the PID controllers above conventional thermostats, by orchestrating setpoint evolution--directly determining equipment durability and output signal stability. Understanding thermal dynamics is required to implement SUR: Match ramp rates with process inertia; synchronize output hardware update intervals and use auto-tuning. AI-driven SUR, which predicts optimal ramps using digital twins, will revolutionize precision temperature control as industries embrace Industry 4.0.

- SV and PV Temperature Control: Industrial Efficiency Explained

- PID Temperature Controller Mounting Guide: DIN Rail, Panel & Surface Methods | Expert