What is the principle of an analog temperature controller? Comprehensive Guide

1.analog temperature controller

Core principle: By comparing the actual temperature with the set temperature through physical and electrical signals, the target range of the two is narrowed by adjusting the heating and cooling modes. The physical signal received by the temperature control element is linearly converted and amplified, and the output is driven in a proportional relationship. Through the linear control element, the continuous signal is converted into the power of the actuator.

Working principle: "Detection - Regulation", by detecting the difference between the actual temperature and the set temperature, it controls the execution to perform self-adjustment work, making it hover within the set value range and eventually stabilize

2.Temperature: Physical signal converted into command to enable the actuator to self-adjust ---------- "temperature" converted into "electrical signal"

The function and classification of temperature physical components

Common temperature-sensitive components: thermocouples, NTC and PTC resistance electronic components, pt100.

The main function of a resistor is to divide the voltage and reduce the ratio of the output voltage. By limiting the output, it indirectly lowers the current and thereby reduces the temperature.

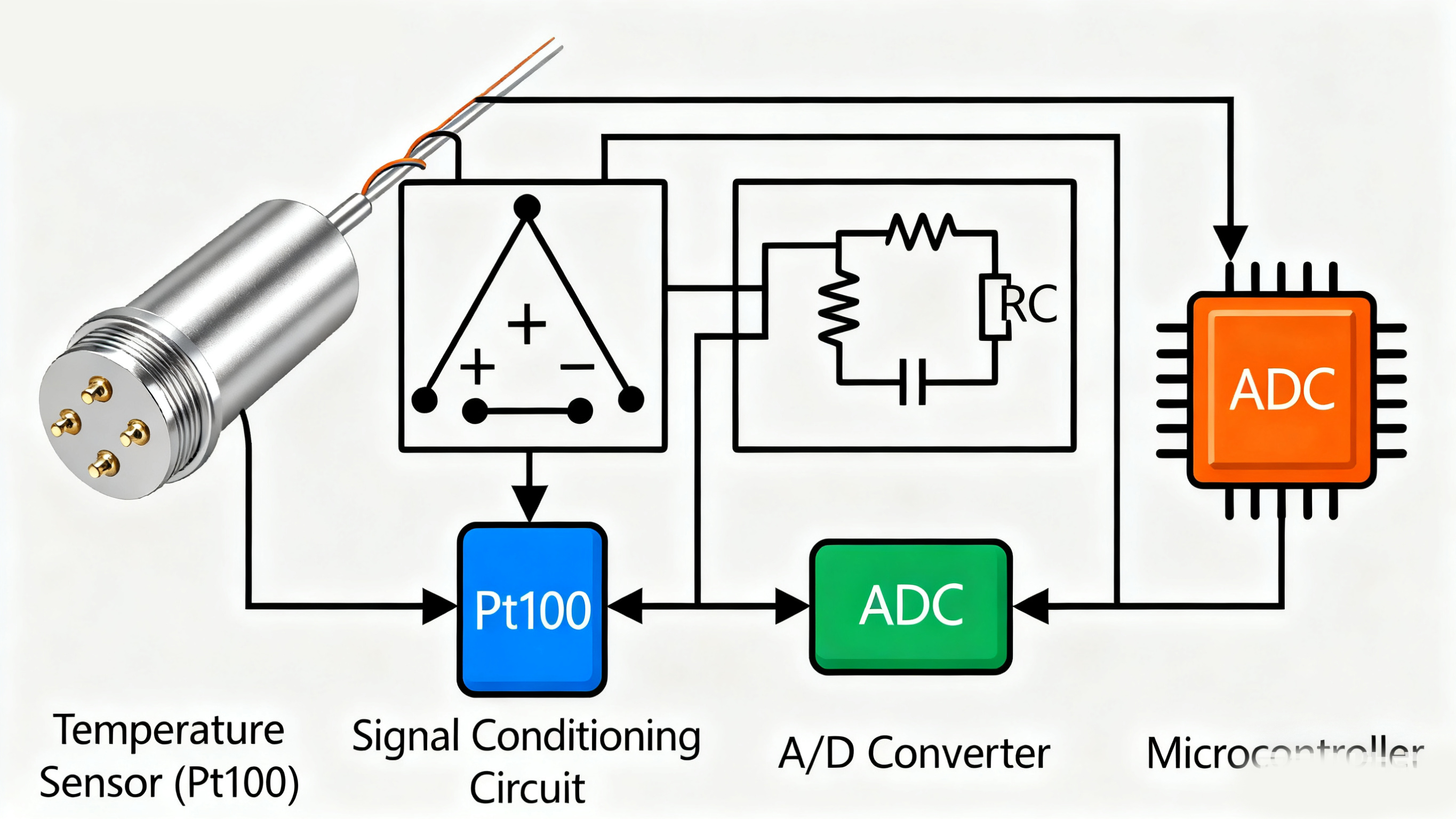

Signal: The sensor measures the temperature sensed by the sensing component and converts the designed measured temperature into a continuous electrical signal

Linear compensation: Control accuracy, through the connection relationship between resistors, converts it into voltage transmission

Filtering and denoising: The electrical signal is output as an analog quantity, and the signal is filtered, denoised and amplified by components to achieve a stable output where the actual value is comparable to the set value

3.output electrical signal = "Target temperature"

Adjust the voltage by the knob position, and use the voltage as a reference to control the target temperature range. If the potentiometer is connected to a 7V voltage, the voltage range at this time is 0 to 7V. At this point, adjust the voltage to see what the actual temperature value is.

ON/OFF is the "decision-making stage" that controls the temperature controller. By adjusting the potentiometer, the temperature instrument senses different temperatures and approaches the set value until it reaches a stable temperature. At this point, the temperature fluctuates continuously until it reaches the target value.

Positional control: Temperature detection and regulation, reference setting, hysteresis comparison, drive execution

When everyone is choosing component types, anti-inductive interference design, self-heating effect, and key points for debugging, it is essential to select and use them properly

Temperature detection element: Select based on the temperature range

Comparators/operational amplifiers: To avoid errors, select those with ultra-low voltage

Drive components: The current must be greater than the actuator load, and pay attention to the rated voltage

Anti-interference: Select a 50HZ power grid, separate strong current from weak current, and connect freewheeling diodes in parallel at both ends of the relay coil

Debugging: Vref matches the Vt corresponding to the temperature

Self-heating: Series resistance limits the current to prevent excessive current from causing the component temperature to rise too high and resulting in inaccurate measurement accuracy

Summary: The core of analog temperature control lies in "analog closed loop", which enables automatic temperature control and can achieve low cost, high reliability and flexible control

- Why does your PID always go out of control? These optimization "pitfalls" must be avoided

- Types of Relays A Comprehensive Guide