How does a pid temperature controller- work

I believe that when everyone uses a thermostat in their daily life, they are always troubled by these several problems. Abnormal temperature control effect, troublesome operation/adaptation, poor stability/durability, and frequent errors

1. Problem points

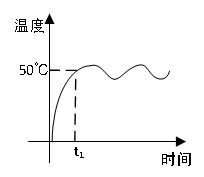

The temperature "rises too high" or "drops too low" (with severe overshoot)

The temperature is "just a little short of the target" (with static deviation)

The temperature fluctuates frequently.

It's troublesome to use and can't be installed/is incompatible

"Unable to connect to the device" (sensor/actuator incompatible)

"Display incomprehensible/Operation complex

Stability and durability issues: "It doesn't last long and frequently malfunctions.

2.In our home environment, the elderly are not familiar with complex thermostats. The temperature may be set too high or drop too low (with severe oversetting), failing to achieve the desired effect. The screen display is unclear, such as kitchen grease covering the thermostat making it hard to see. There are also situations like the electric oven getting burnt, as well as a series of problems encountered in industrial environments

For instance, what we often see is setting the temperature of the temperature control meter at 20℃, but the actual temperature remains stable at 18℃, never reaching the target and always just a little short of it (reaching too low), or setting it at 50℃, but only stopping when the actual temperature reaches 55℃ (reaching too high).

Another issue is that the temperature fluctuates back and forth within a certain range, constantly fluctuating within the target value range, failing to achieve

the desired effect

3. Some people find it difficult to install the temperature controller when using it due to incompatibility, or they can't connect the device, which causes them a lot of trouble and they don't know what to do

| 1 16 din temperature controller |

| 4 1 din temperature controller |

| 1 2 din temperature controller |

| 1 4 din temperature controller |

| 1 8 din temperature controller |

4. Another issue is that the display page is hard to understand - Xiaobai, I wonder if you have encountered any problems here

Why does such a problem occur?

Ok. First of all, let's take a closer look at the principle of temperature control PID

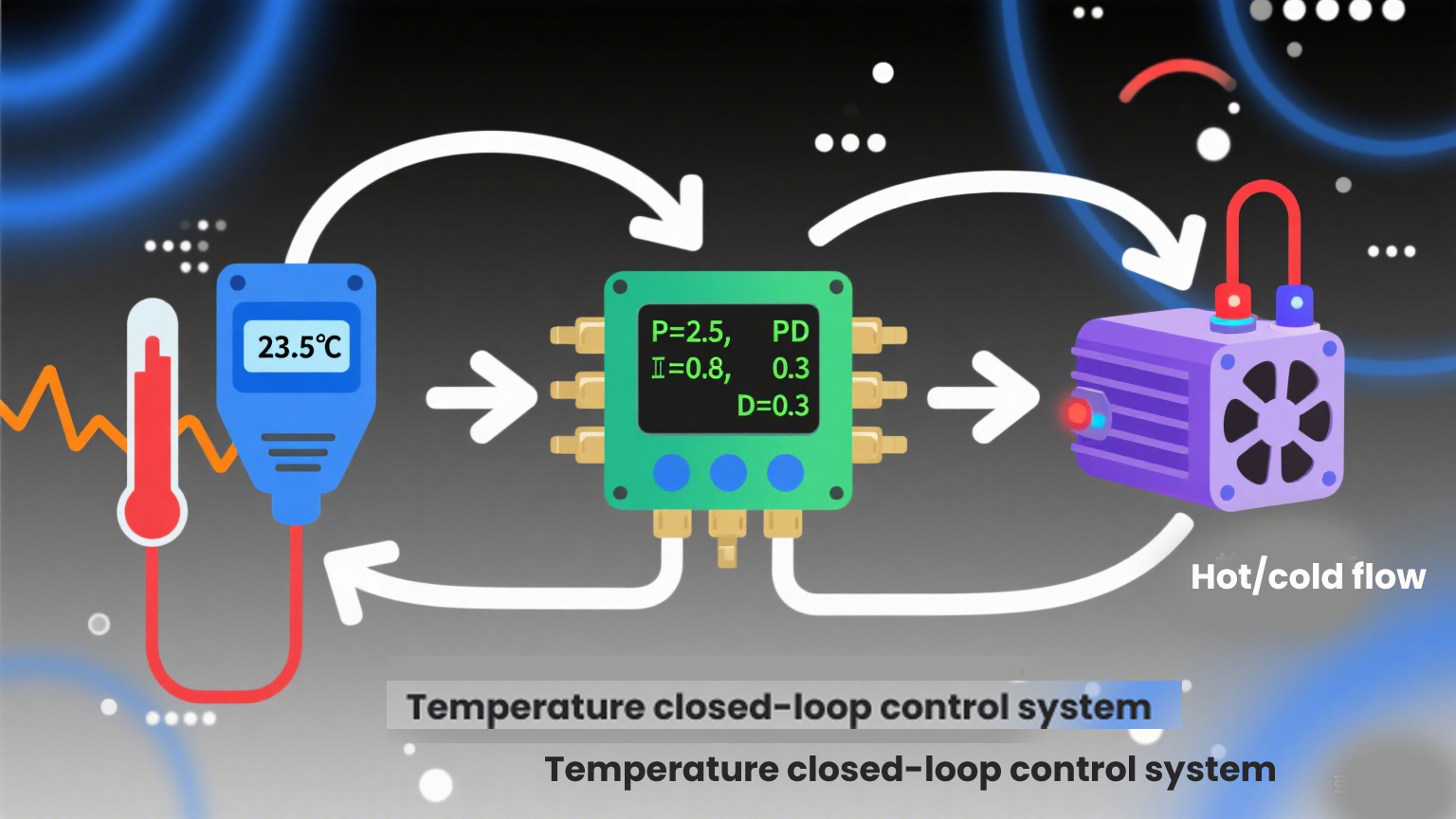

The PID principle, also known as the PID algorithm, is collectively referred to as: signal acquisition → algorithm calculation → execution and output

PID, proportion, integral, differential --------PID control

The core objective of PID: To address "temperature deviation

The three steps of PID: proportion, integral, and differential - the corresponding letters are represented as: proportion (P), integral (I), and differential (D)

1.P ratio: Adjust the output based on the current deviation size: The greater the deviation, the stronger the adjustment force; conversely, the smaller the deviation, the weaker the adjustment force

For instance, take "adjusting the faucet" as an example: if the water temperature is far from the target (for instance, the target is 30℃ but the actual temperature is 10℃), open the hot water valve to the maximum. When approaching the target (the actual temperature is 28℃), close the valve slightly. Controlling the deviation well is the role of "P" - quick response

2. The i-integral adjusts the output based on the cumulative amount of past deviations. For instance, if the actual temperature is always 3℃ lower than the target, the integral will continuously "intensify" the adjustment force until the deviation gradually decreases and disappears. (Just like if the water temperature is always 2℃ lower than the target, the valve is gradually opened a little wider until the water temperature meets the standard.) To avoid leaving "residual deviation", this is what we often call "static deviation" in our daily life.

3.D Differential: We commonly call it "braking prediction". In our daily life, when we drive, we stop at red lights and go at green lights. Before getting completely close, we gently press the brake in advance. The differential process follows the same logic - predicting the "future trend" of the deviation and intervening in advance. For instance, if the deviation rapidly increases (such as a sudden drop in temperature), increase the adjustment intensity in advance. If the deviation rapidly decreases (the temperature quickly exceeds the target), reduce the force in advance.

This is the function of PID, proportion, integral and differential

So, what components are needed to use a temperature controller?

Temperature sensor/actuator/power module/connecting wire

What roles do they respectively play? ---- temperature measurement - temperature control - execution

1. Temperature sensor The purpose is to collect the temperature of the target environment/object and feed it back to the controller - usually a single wire is used to collect the signal. Common types include K,E, and J wire thermocouples and thermal resistors (PT100 CU50), such as K type/J type, which are relatively heat-resistant and suitable for use in industrial furnaces and ovens, while PT100 has high precision and is suitable for use in normal temperature scenarios

2. It receives instructions from the controller and executes "heating/cooling/on/off". When the controller detects that "the current temperature is less than the target temperature", it quickly sends a power-on heating instruction to the actuator. After the actuator is powered on, it heats up and releases heat until the temperature reaches the target value. Then, the actuator sends another instruction to stop releasing heat, just like a household water heater. You need to set the water temperature to a certain level.

Perception and judgment - Instruction Sending - Execution of heating - Stop heating

3. Power module: It provides stable power for controllers, sensors, and actuators. Most industrial controllers require DC24V (with a switching power supply, such as 24V/2A), while household controllers mostly directly use AC220V.

4. Connecting wires: Transmit power, temperature signals, and control signals. The power wire is responsible for delivering the energy for the operation of the equipment. Signal wires are responsible for transmitting temperature data (sensing signals) and control instructions (decision signals).

To sum up, "When the deviation is large, make a sudden adjustment (P); when the deviation accumulates, make up for it (I); when the change is rapid, apply the brakes first (D) - the three work in coordination to achieve - fast, accurate and resolute.