The PID control for temperature: principles, implementation & tuning

Understand PID temperature control. Learn how PID works, tune and implement it and how to troubleshoot. Included are examples and other resources.

1. Understanding PID control for temperature

The PID controller represents an important improvement over simple control strategies. A PID controller calculates the error as the difference of a process variable measured (here, temperature) from a setpoint. The PID controller adjusts process input (such as power to a heating or cooling device) according to three different terms.

The proportional action (P): This component responds to the magnitude of error. The P action will increase the output signal if the temperature falls below the presetpoint. The corrective actions are large for a big error, but small errors result in smaller adjustments. Proportional Gain Kp determines the sensitivity of such an action. Although P control is quick to respond, it can leave a residual error known as an offset if other components are not used.

Integral Action (I): The part that addresses the limitations of the P Control by taking into account the cumulative error over time. Integral summarizes past errors continuously and takes corrective actions to eliminate the residual offset caused by Proportional. The I action increases the output gradually if the temperature is consistently below the presetpoint. Integral time (Ti) determines the rate of this integral action. Although I control is effective in eliminating offsets, it can initially be slow to react.

Derived (D) action: The component predicts errors in the future by reacting on the rate at which the error signal changes. The D action will apply a brake force to the approaching approach if the temperature rises rapidly. This prevents it from exceeding the setpoint. If the temperature falls too rapidly, the D action will provide a small boost in order to offset the drop. Derivative Time Constant Td controls the sensitivity of the system to rate changes. The D-control helps stabilize the system and reduce overshoot. It also improves response time.

For effective temperature control, it is important to balance these three actions precisely. Engineers can adjust parameters such as Kp, Ti and Td to optimize performance, regardless of whether the PID controller is a standalone device, an integrated part of Programmable Logic Controllers or PC software. Sources like Control Engineering’s article about PID fundamentals can provide solid theoretical support.

2. Plan Your Temperature Control System

The implementation of a system begins well before any wires are connected.

Pick the Right Controller Find a controller for your application. Take into account factors like:

Types of input/output: Can it receive the temperature sensor signals (e.g. Thermocouple Type k, RTD Pt100)? Is it able to provide you with the correct output for your final control element?

Control algorithm: Does the control algorithm offer advanced features, such as anti-windup or filter options, and communication protocols, like Modbus?

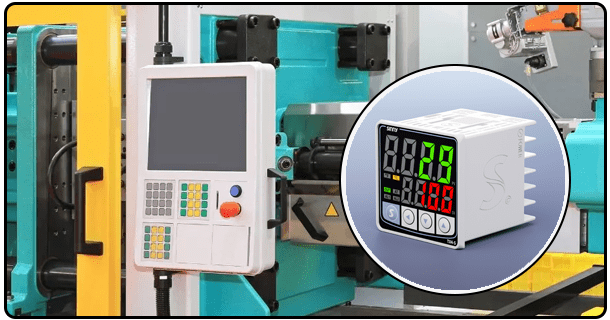

Display & Interface: Which level of interface do you need for monitoring and configuring?

Safety considerations: Defining any safety requirements such as alarms for high/low temperatures or emergency shut-down points and ensuring that the control system is able to enforce them.

Collect Documentation Access the manual of the controller, sensor datasheets, and actuator documentation. This information is essential for a successful implementation.

3. PID Control System Implementation

This step involves connecting all the parts according to their design.

Hardware Connectivity:

Connecting a Temperature Sensor: Attach the sensor of your choice (RTD or Thermocouple), to the input terminals designated on the PID Controller. The wiring diagram in the manual of the controller should be followed to the letter.

Connecting an Actuator: Wire up the final control element, such as a relay, SSR or other similar device. Connect the output terminals of the controller. Check that the datasheet of the actuator and controller match. Assuring correct wiring of load connections (NO/NC contacts, e.g.) is important for relays and SSRs.

Connecting power: Refer to the manual again for instructions on how to connect the necessary power source (normally AC orDC) at the input terminals of the controller. All connections must be insulated and secure. Wiring safety is of paramount importance.

Wiring diagrams: Stress the importance of consulting manufacturer diagrams to ensure accuracy and safety.

4. Setting up the temperature PID controller

The configuration transforms raw hardware into an operational control system. It requires the careful adjustment of parameters.

Configuring the Controller: Enter programming mode by using the keypad or buttons on your controller or through a PC-interface software.

Set the Setpoint: Define what temperature you want the system to reach.

Setting Input Type: Select the input type you want (e.g. RTD, TC, Type K voltage), and if necessary, any scaling compensation or cold junction compensation.

Setting Output Type: Select the type of output (e.g. Relay or PWM), and make sure it is compatible with the actuator. If necessary, set the range of control.

Setup of initial PID parameters: Often the most complex and crucial step. Initial parameters are often adjusted ("tuning") Most controllers have an automatic tuning feature. This performs tests (e.g. a change of setpoint in a small step) and calculates the appropriate P, I, D values. Refer to the established tuning methods if manual adjustment is necessary. You can find valuable information in resources like Tuning Strategies for PID and Control Engineering’s tuning guide. Begin with conservative values, and then adjust them incrementally as you monitor the response of your process. The key parameters are:

Proportional gain (Kp). controls the response to the error. A value that is too high can cause oscillation, while a value below this level will result in a slow reaction and an offset.

Integral time (Ti). Determines the speed at which the error is corrected. A time that is too short may cause instabilities; a time that is excessively long can result in offset.

Derived Time Constant Td: Regulates anticipation by analyzing the rate of error change. A poorly tuned system can cause noise and instability.

Set up alarms: Configure the high/low temperatures limit alarms for notifications or safety action.

Output filter and dampening: These features can be used to reduce oscillations and sensor noise.

Save Configuration Make sure settings are stored in the memory of the controller according to instructions.

5. Temperature Control Testing and Verification

It is important to test thoroughly after physical configuration and connection in order to ensure correct performance and confirm the operation.

Initial checks: Check all connections and settings, including power, wiring, and the initial setting.

Closed Loop Response: Modify the Setpoint (SP) of the system and observe its behaviour. Check for:

Response time: When does temperature change start?

Accuracy : Is the temperature reaching and maintaining the setpoint?

Overshoot : Is the temperature significantly higher than the setpoint?

Stability - Is it stable or oscillating?

Stable-State error (Offset). Does the temperature remain constant slightly above or below the setpoint when the steady state error is applied?

Actuator response: Watch the actuator to make sure it responds correctly to control signals (relay clicking, SSR changes in power, changes to fan speed).

Data Logging: Enable data logging if the controller allows it to track temperature and outputs over time. This will allow for an in-depth analysis.

PID Tuning parameters: Re-evaluate the tuning parameters based on initial performance. You may need to make adjustments repeatedly in order to get the best results. If available, use charts, calculators or simulation software.

Troubleshooting for Common Problems at Different Temperatures

Even with careful planning and tuning there can be problems. Here are some of the most common issues and possible solutions in temperature control.

Fluctuations in Temperature / Overshoots:

Cause Too aggressive proportional or derivative action (too large Kp or Td), insufficient filtering or process stability.

Solution Reduce Kp or Ti, or reduce Td. Verify output filter settings. Check that the process isn't the source of any fluctuations.

Steady State Error (Offset), Slow response:

Cause Insufficient Integral Action (Ti is too large) and/or too conservative proportional gain (Kp is too low). The filter settings could be set too aggressively.

Solution Either increase proportional gain (increase Kp) or decrease Integral action. Check that the integral time corresponds to the response time of the system.

Sensor Reading Errors:

Cause Poor wiring (loose or broken connections, noise from electrical interference, etc.), sensor calibration drift and incorrect cold junction compensation.

Resolution: Check sensor configuration on the controller. Verify sensor connections and wiring. Recalibrate the sensor, or controller's reference for cold junction. Separately calibrated thermometers can be used.

6.Actuator not responding correctly:

Cause Improper actuator wiring, actuator failure, incompatible output signals from controller, defective relay/SSR.

Solution : Consult datasheet of actuator. Verify that the wiring is in accordance with specifications. Check that the output of the controller matches the input signal requirements for the actuator. If possible, test the actuator on its own.

Stability issues (Oscillation).

Cause Too aggressive proportional or derivative action (too large Kp or Td), Integral Windup (integrator saturated).

Solution Increase Ti or decrease Kp. Reduce Td. If available, implement or test the Anti-Windup function. If necessary, reduce the output range of the controller.

Consult the manual of the PID controller before you begin troubleshooting. Control.com and other online forums can be excellent resources to share experiences.

- Overview of the Article: PID controllers and Temperature Control

- led pid digital temperature controller